Pipeline sweeping fuzzy control system of ball mill differential pressure thickness measurement system

A technology of fuzzy control system and ball mill, which is applied in the direction of electrical program control, displaying liquid level indicator through pressure measurement, program control in sequence/logic controller, etc. Inaccurate measurement values and other problems, to achieve the effect of improving the efficiency of the main engine, reducing the frequency of pull-in and closing, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

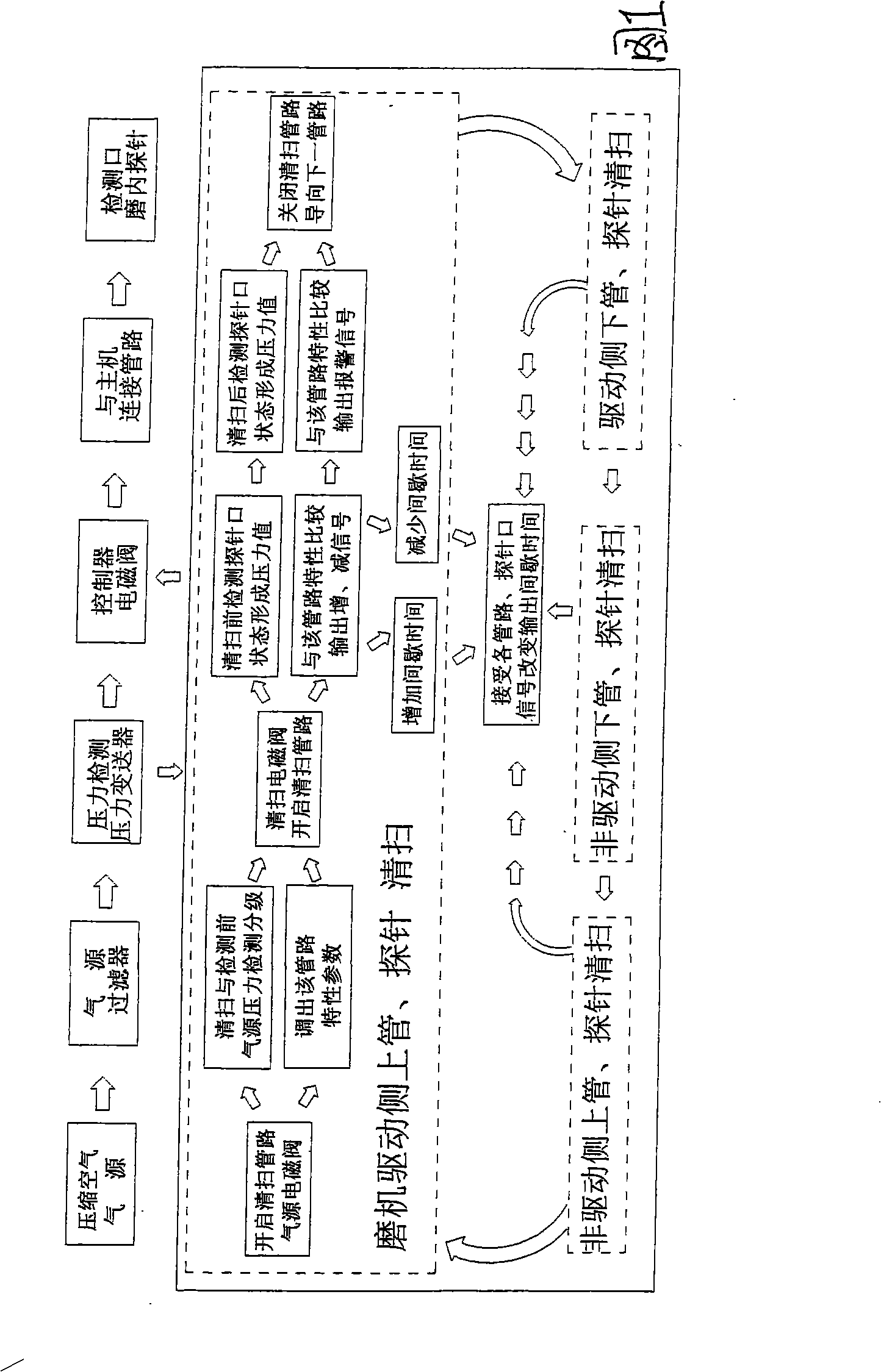

[0015] A pipe cleaning fuzzy control system for a differential pressure thickness measurement system of a ball mill, including upper and lower probes on the driving side of the ball mill, upper and lower probes on the non-driving side, and a pressure transmitter on the pipeline between the probe 1 and the gas source The pressure transmitter 2 and the pressure transmitter 2 are connected to the programmable logic controller (PLC) 3. The programmable controller controls the cleaning air source solenoid valve, The opening and closing of the solenoid valves of each cleaning pipeline obtains the pressure value formed by the state of the probe port before and after cleaning, and through comparison and calculation, the working interval time of the solenoid valve for controlling the cleaning air source and the solenoid valve of each cleaning pipeline is set to change. .

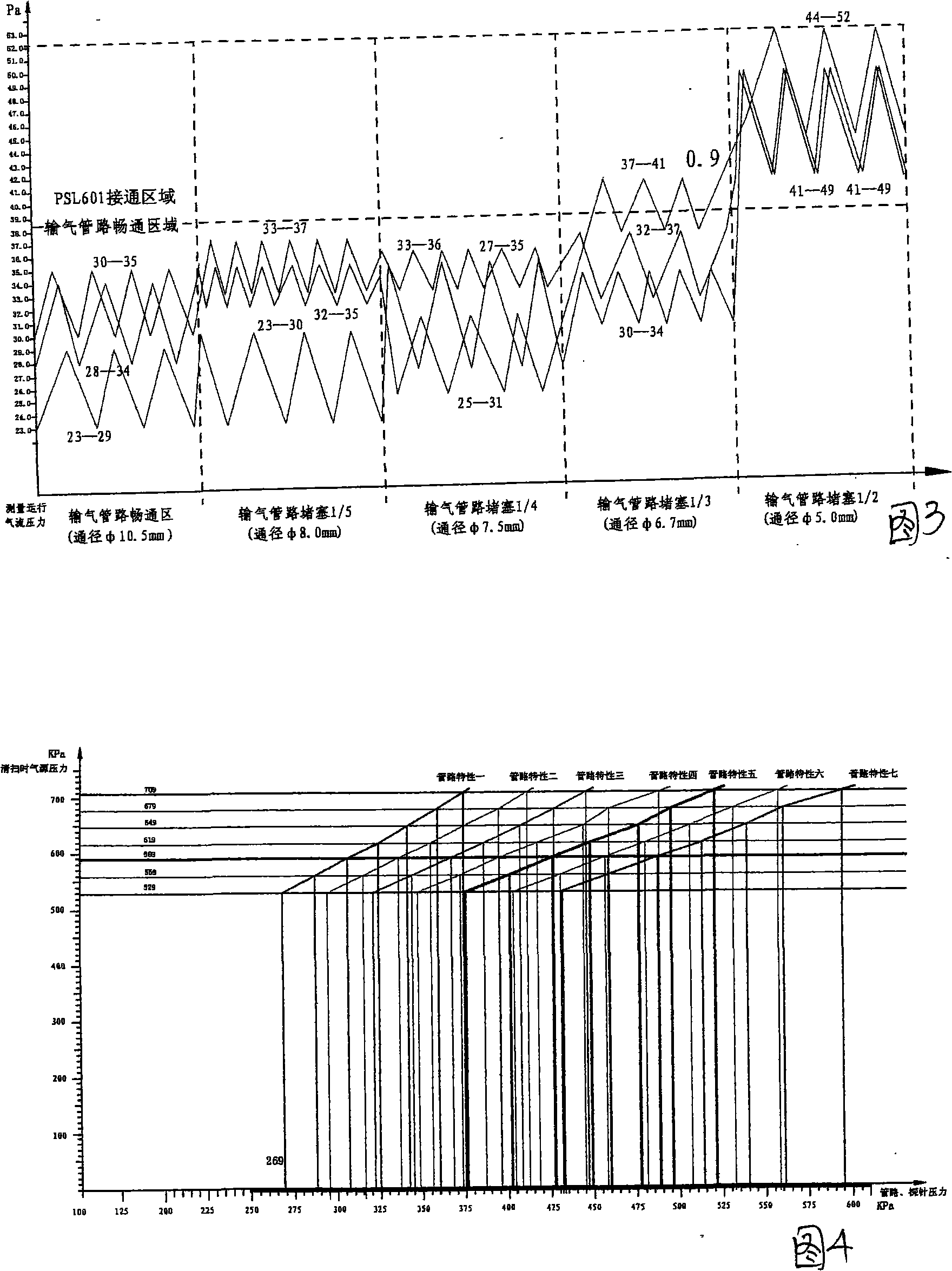

[0016] In Figure 4, since each device has four pipelines (and probe ports), each pipeline has different lengths an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com