Boron micro-alloying low-carbon two-phase steel produced by hot continuous rolling process and its preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The results of some examples are listed below. The three components are smelted in a vacuum furnace. After demoulding, they are directly put into the heating furnace, heated for 25 minutes, and the furnace temperature is controlled to 1100°C. Each component is rolled into two specifications, and the composition process and properties are shown in Tables 2-4.

[0026] Table 2 embodiment measured chemical composition (weight fraction %, all the other are Fe)

[0027] instance number

[0028] instance number

[0029] Table 3 embodiment measured process parameter

[0030] example

[0031] Table 4 embodiment measured performance

[0032] example

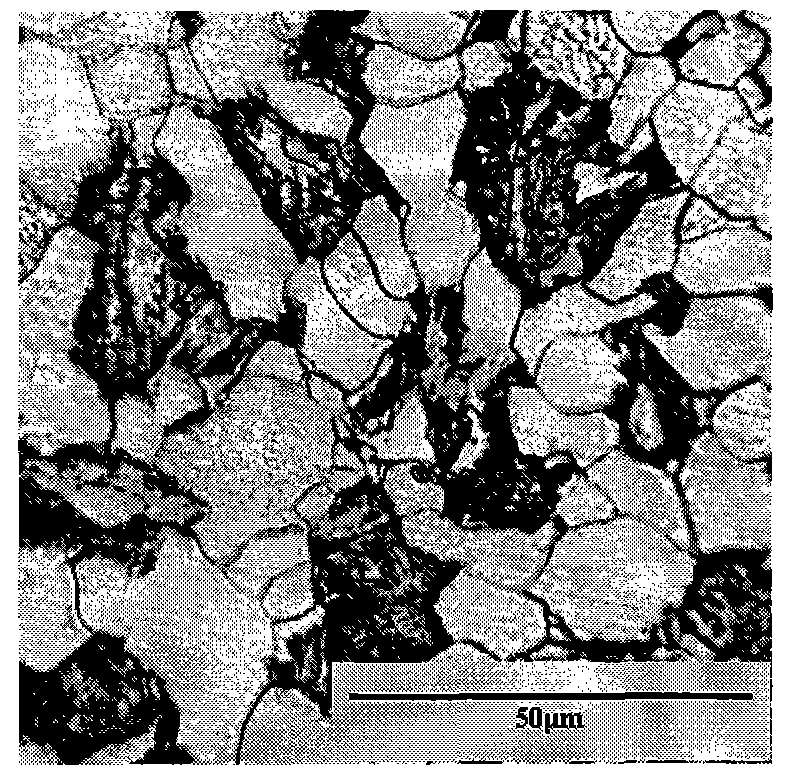

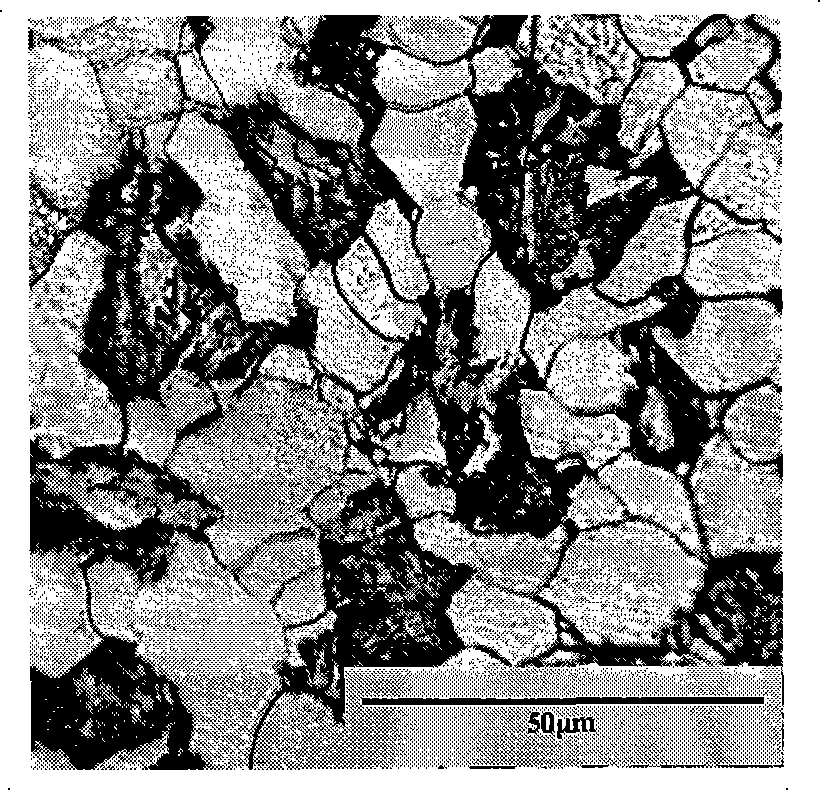

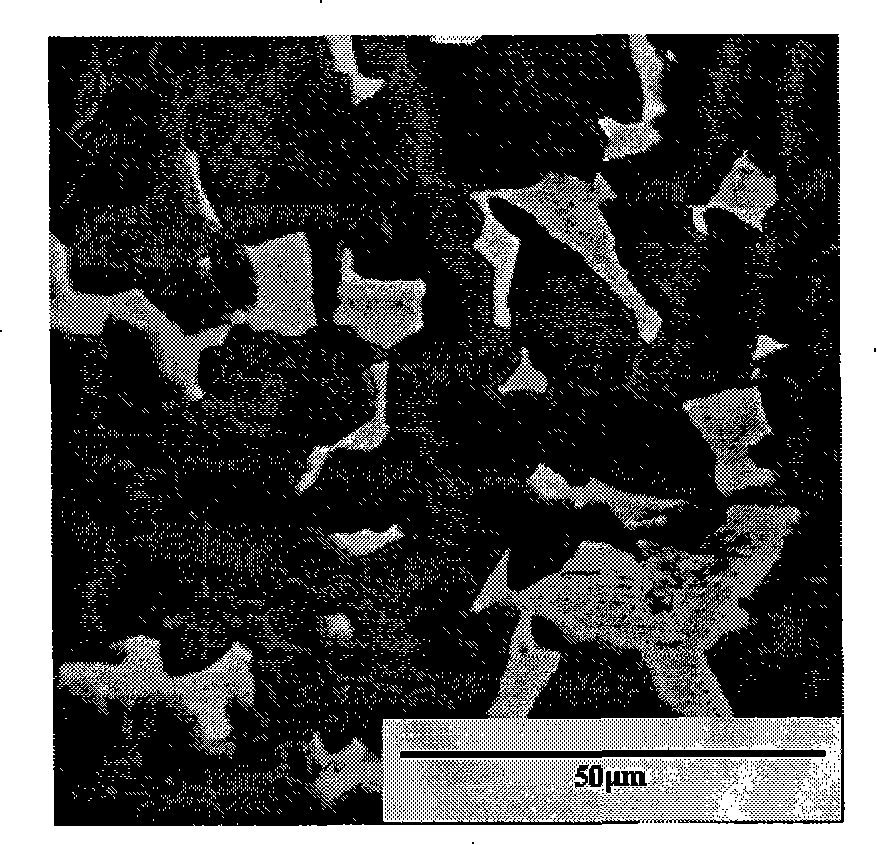

[0033] It can be seen from Figure 1 that the ferrite exists in the form of polygons in the duplex structure, and the martensite is distributed between the ferrites in the form of islands; it can be seen from Figure 2 that after being corroded by Lepera reagent, the martensite is bright white...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com