Flue gas powder dust and characteristic gas simultaneous on-line monitoring method and apparatus

A monitoring device and flue gas technology, which is applied in the field of characteristic gas monitoring and flue gas dust, can solve the problems of inconvenient comprehensive evaluation of flue gas, difficult data integration, and cumbersome measurement repetition, etc. It achieves compact structure, less space occupation, and reduced connection The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

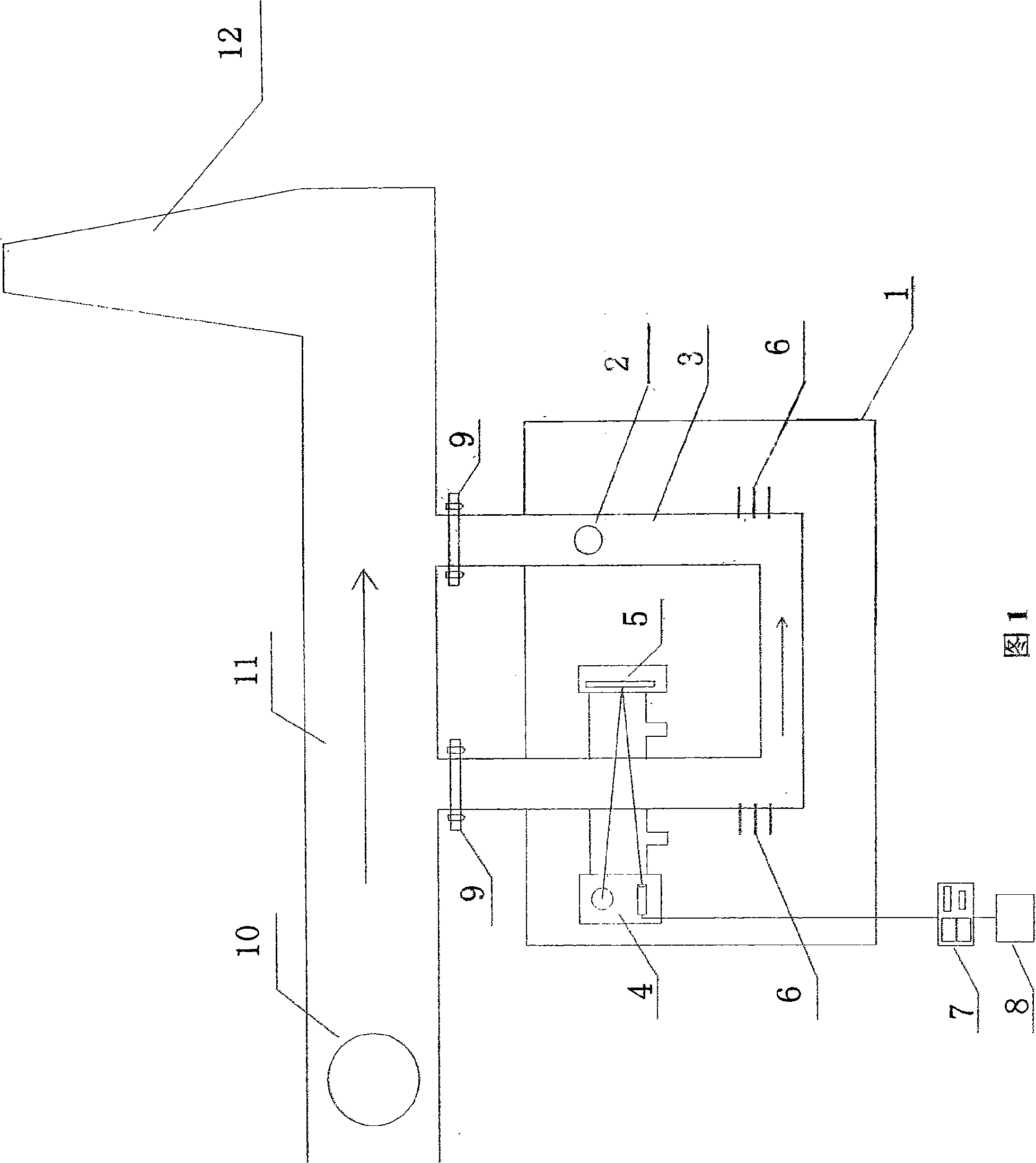

[0047] Embodiment 1: (simultaneous online monitoring device for flue gas dust and characteristic gas of the present invention)

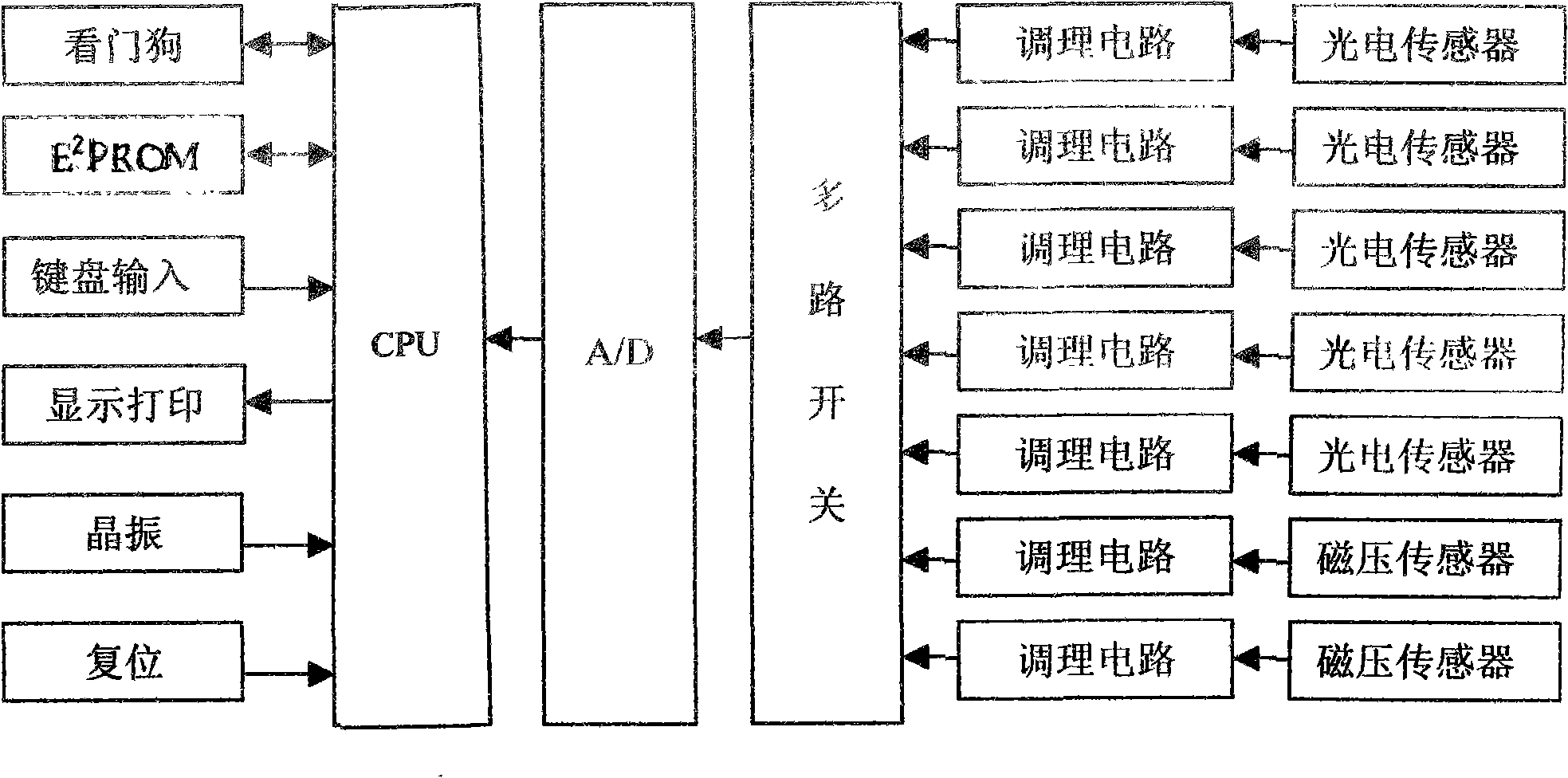

[0048] As can be seen from accompanying drawing 1, a kind of flue gas dust of the present invention and characteristic gas on-line monitoring device simultaneously, it is connected with chimney 12 and it is provided with boiler flue 11 side walls of induced draft fan 10, is provided with through flange 9 phase Connect the fixed U-shaped flue gas bypass pipe 3. The U-shaped flue gas bypass pipe 3 is fixed on the housing 1 of the device; on one side of the U-shaped flue gas bypass pipe 3, a transmitting and receiving device 4 for measuring the flue gas, and a reflector on the other side of the U-shaped flue gas bypass pipe are installed. Device 5; two groups of three multifunctional probes 6 for measuring the characteristic gas are symmetrically installed on the outside of the inlet and outlet pipes of the U-shaped flue gas bypass pipe 3; in the monito...

Embodiment 2

[0051] Embodiment 2: (application of the online monitoring method for flue gas dust and characteristic gas at the same time of the present invention)

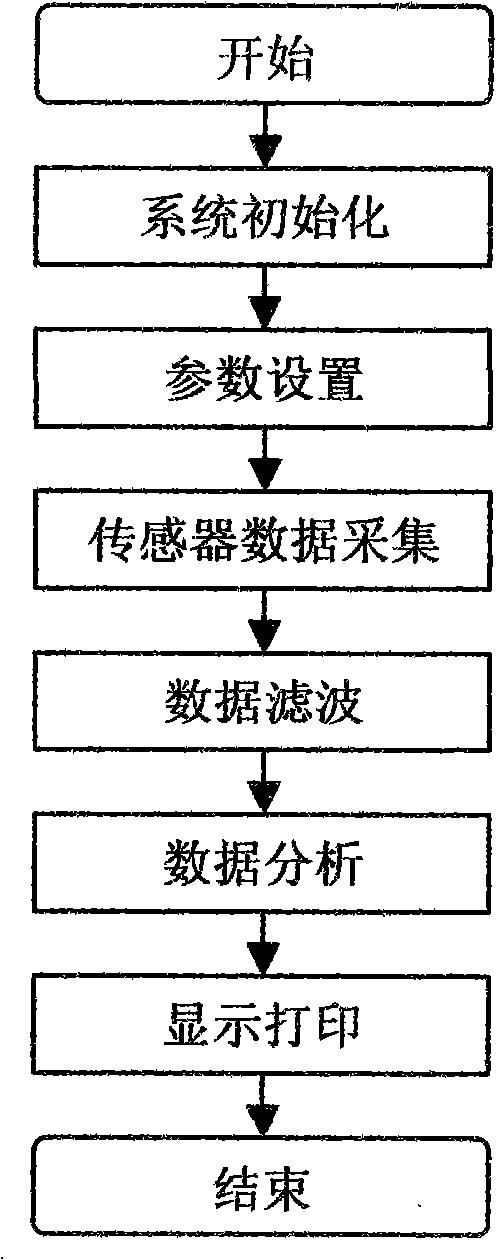

[0052] It can be seen from Figure 1 that the simultaneous online monitoring method of flue gas dust and characteristic gas is composed of the following processes and steps in sequence:

[0053] 1) Connect and fix the U-shaped flue gas bypass pipe 3 of the flue gas dust and characteristic gas online monitoring device on the side wall of the boiler flue 11, and start the fan 2 to ensure that there is enough air in the U-shaped flue gas bypass pipe 3. flue gas flow;

[0054] 2) Measurement of flue gas dust: the flue gas flows through the U-shaped flue gas bypass pipe 3, and the laser emitted by the transmitter of the transmitting and receiving device 4 installed on the side of the U-shaped flue gas bypass pipe 3 intake pipe, The passing flue gas is reflected by the baffle plate of the reflecting device 5 symmetrically installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com