Process for winding tyre surface and system thereof

A tire tread and film technology, which is applied in the tire tread winding method and its system field, can solve the problems of film quality fluctuations, irregularities, and dimensional accuracy errors of the wound tread, so as to reduce tensile deformation, improve quality, The effect of improving the winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

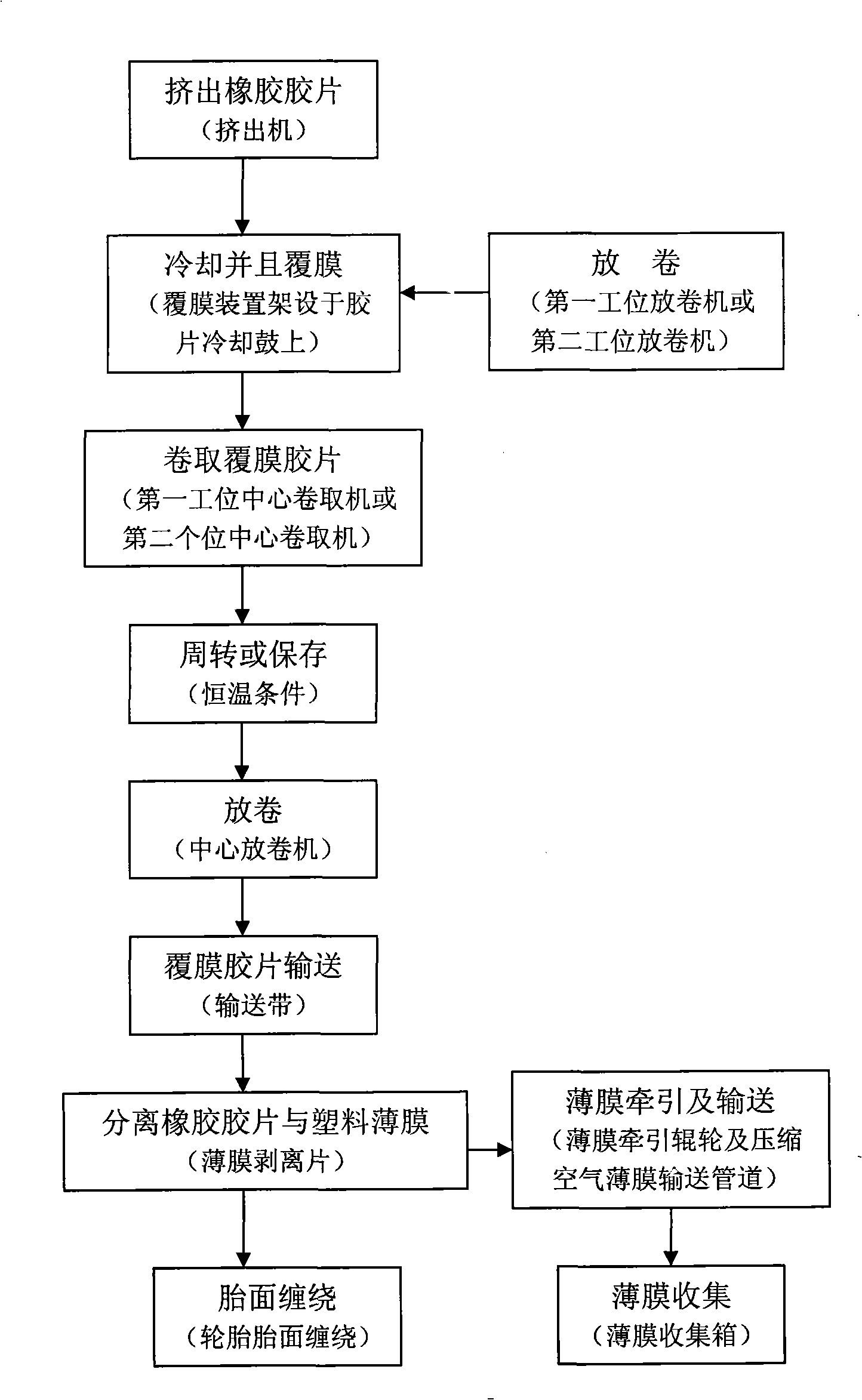

[0023] Such as figure 1 As shown, the tire tread winding system of the present invention is composed of a first process device and a second process device. The first process device includes an extruder, a film cooling roll, a film covering mechanism and a coiling mechanism, and the second process device includes a centrally placed Winding machine, film and film separating mechanism and tread winding machine; according to the production and conveying direction of the film, the installation positions of each mechanism are: extruder, film cooling roller and laminating mechanism, coiling mechanism, central unwinding machine, Thin film film separation mechanism, tread winding machine.

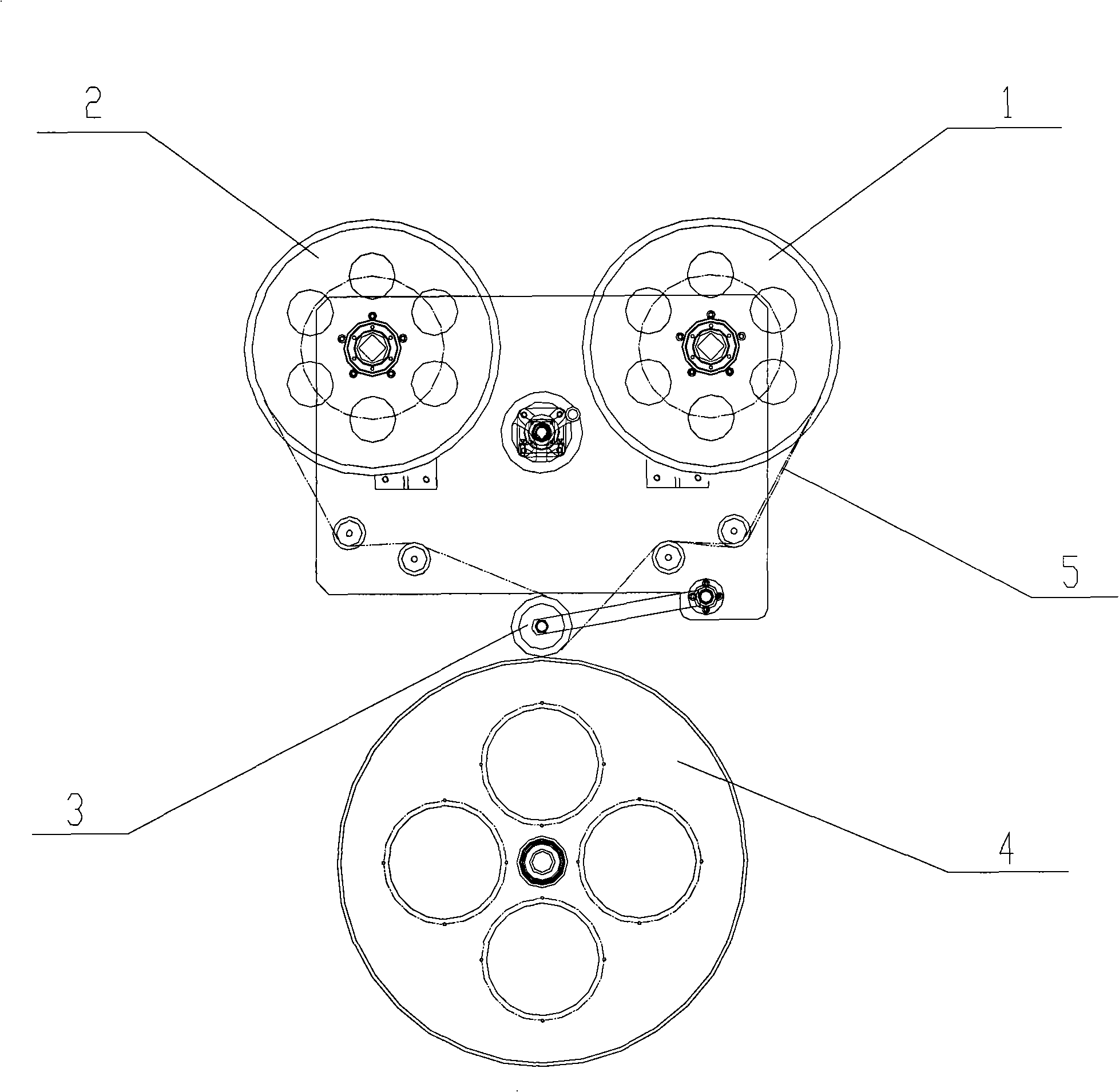

[0024] Among them, the laminating mechanism is erected above the film cooling roller, including the film unwinder at the first station, the film unwinder at the second station, and the bonding rubber roller.

[0025] The coiling mechanism consists of a conveying frame, a center coiler at the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com