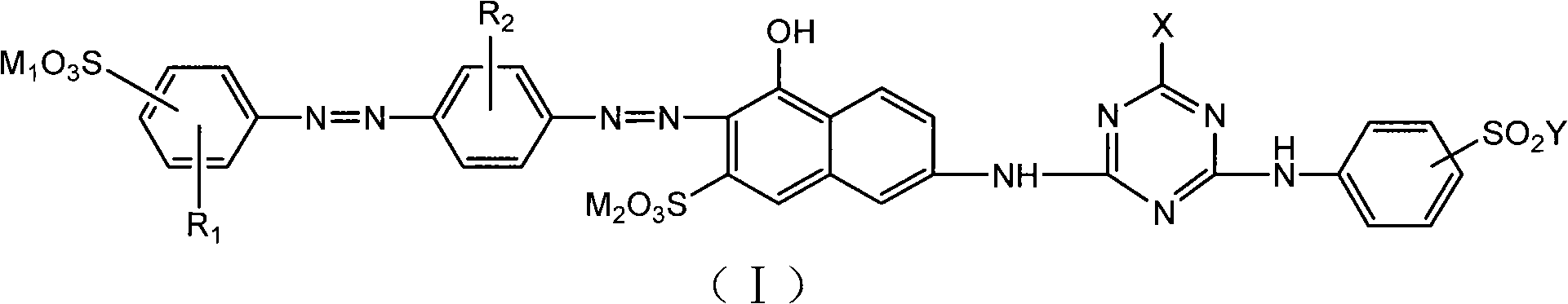

Red disazo dye compound, preparation method and composition thereof

A technology of disazo dyes and compounds, applied in the direction of azo dyes, chemical instruments and methods, dyeing methods, etc., can solve the problems of old textile appearance, poor wet fastness, staining, etc., and achieve bright colors and wet Excellent treatment fastness and high fixation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. The first condensation:

[0042] Add 11.95 g of acid J of formula (III-1) into 150 ml of water, and stir to dissolve.

[0043]Mix and beat 9.7 grams of cyanuric chloride of formula (IV-1), 50 ml of water, 50 grams of ice and 0.1 gram of dispersant MF for about 1 hour, control the temperature at 0-3°C, and slowly add the above-mentioned J acid solution under stirring, Use 10% soda ash to adjust the pH value to 2.8-3.2, and stir and react at 0-5°C for 2.5 hours, then use 10% soda ash to control the pH value to 3.8-4.2, and continue to stir and react at 0-5°C for 3 hours to obtain the formula The first condensation product of (a1).

[0044]

[0045] 2. Coupling reaction:

[0046] Add 13.85g of p-aminoazobenzene-4-sulfonic acid of formula (II-1) into 250ml of hot water at 50-60°C, stir to dissolve, then add 3.62g of 30% sodium nitrite (sodium nitrite) solution, and stir Uniform, while cooling to 20 ~ 25 ℃ for later use. Under stirring, the aforementioned p-aminoaz...

Embodiment 2

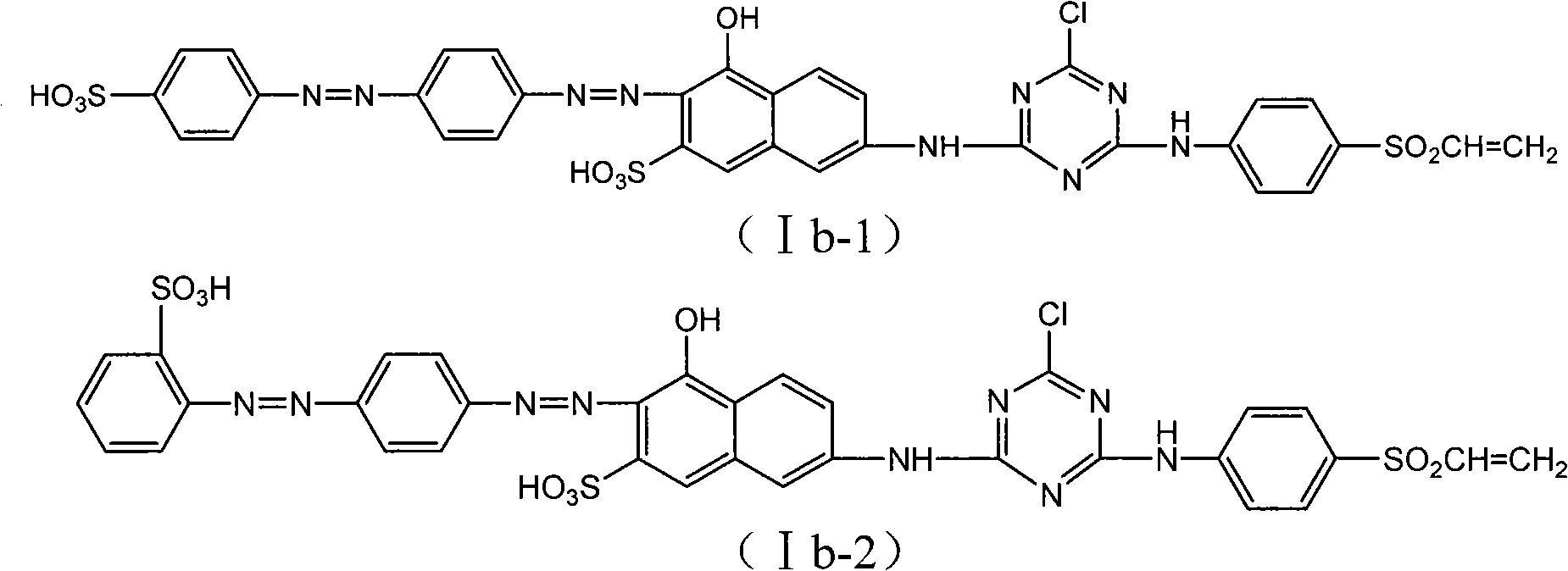

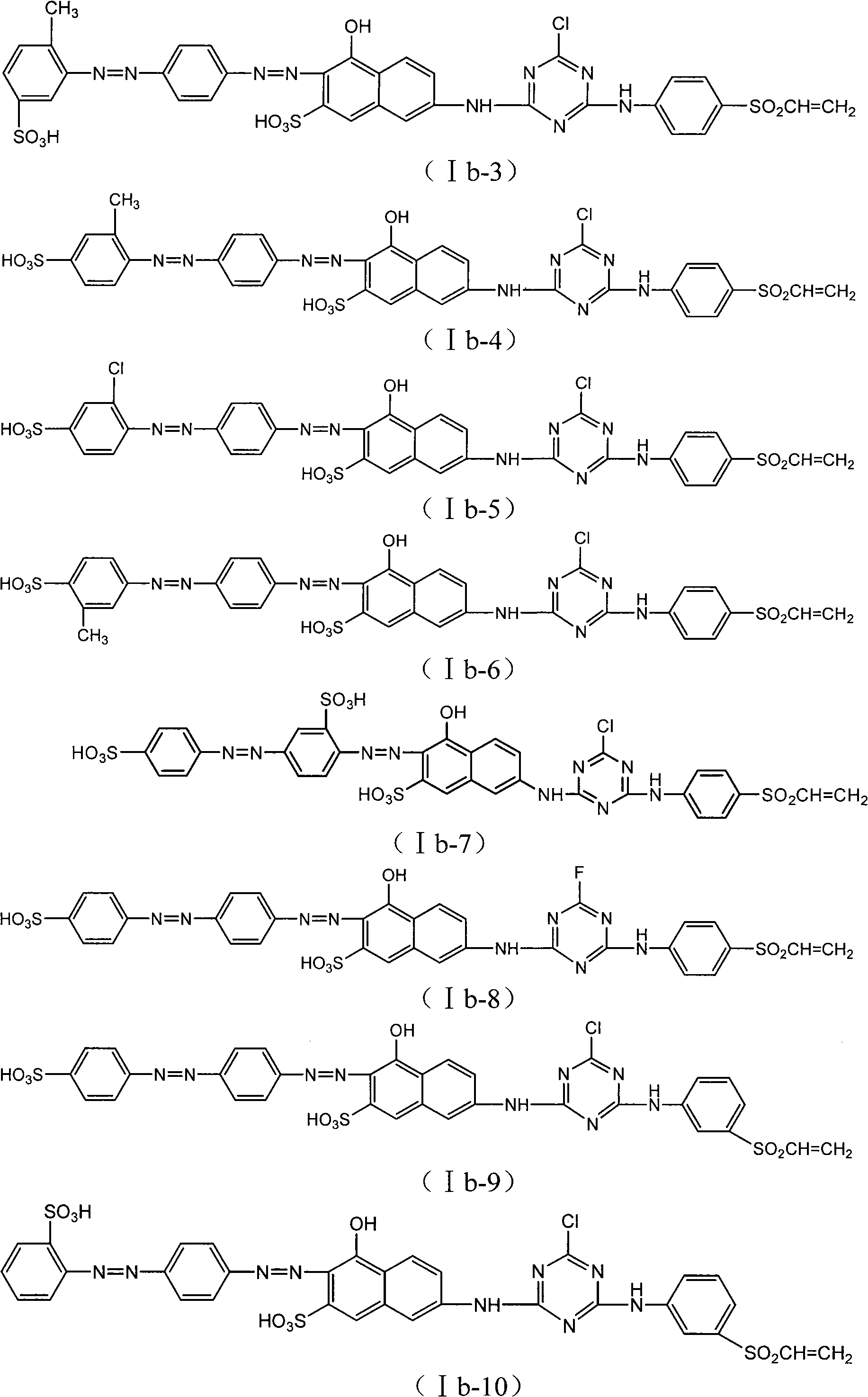

[0060] According to the preparation method of Example 1, use the cyanuric halide of the formula (IV) in the following table 1 and J acid to carry out the first condensation; then carry out the coupling reaction with the diazonium salt of the amine compound shown in the formula (II); coupling Product and the amine compound shown in formula (V) carry out condensation for the second time; Condensation product can make the red disazo dye compound shown in formula (Ia) in corresponding table 2 through aftertreatment; Further, without aftertreatment The dicondensation product can also continue to be hydrolyzed, and then do the post-treatment of the dye to obtain the red disazo dye compound shown in the formula (Ib) in the corresponding table 2.

[0061] Table 1

[0062]

[0063]

[0064] Table 2

[0065]

[0066]

[0067]

[0068]

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com