Self sealed self decompressed coal seam sampling method and apparatus

A sampling device and self-extracting technology, which are applied in sampling devices, undisturbed core extraction devices, and earthwork drilling, etc., can solve the problems of coal sample gas leakage, unreliability, failure of pressure measurement results, etc. Rapid desorption and solving the effect of air pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below through the accompanying drawings and examples.

[0019] The key to the direct measurement of gas content is to minimize the gas loss during the coal sampling process. Studies have shown that once the coal sample is cut, the gas desorption process begins under normal pressure conditions. How to ensure less gas leakage during the gas sampling process is the key key to the invention.

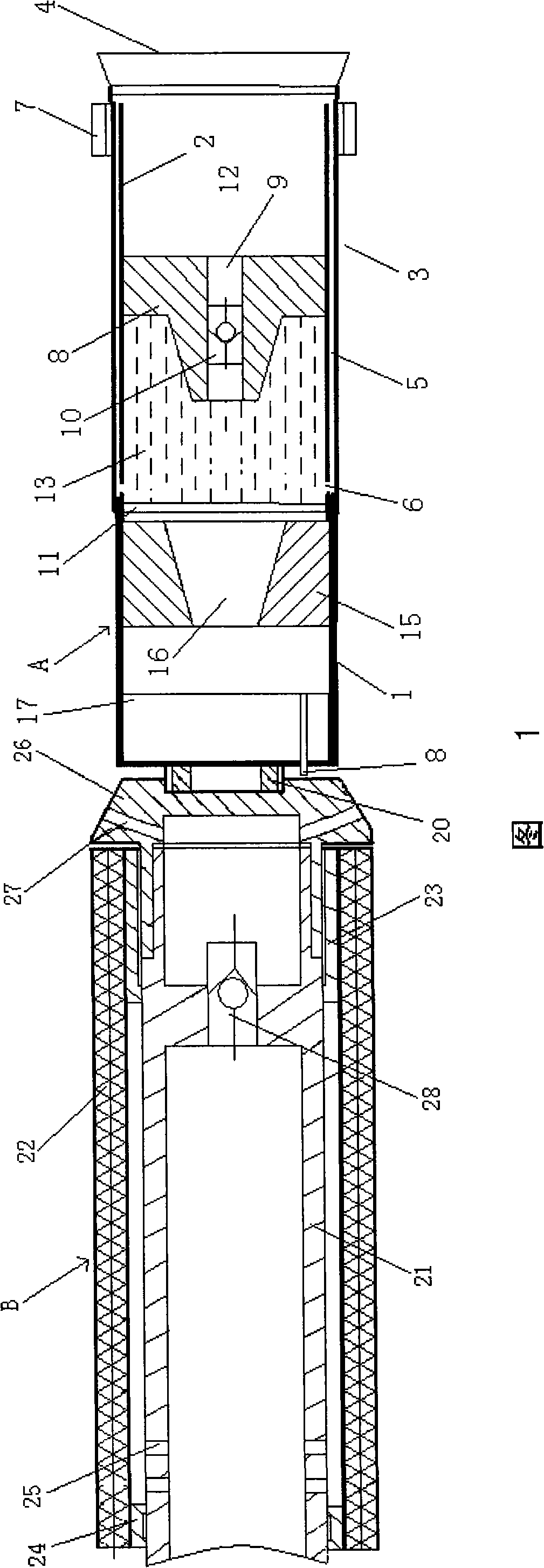

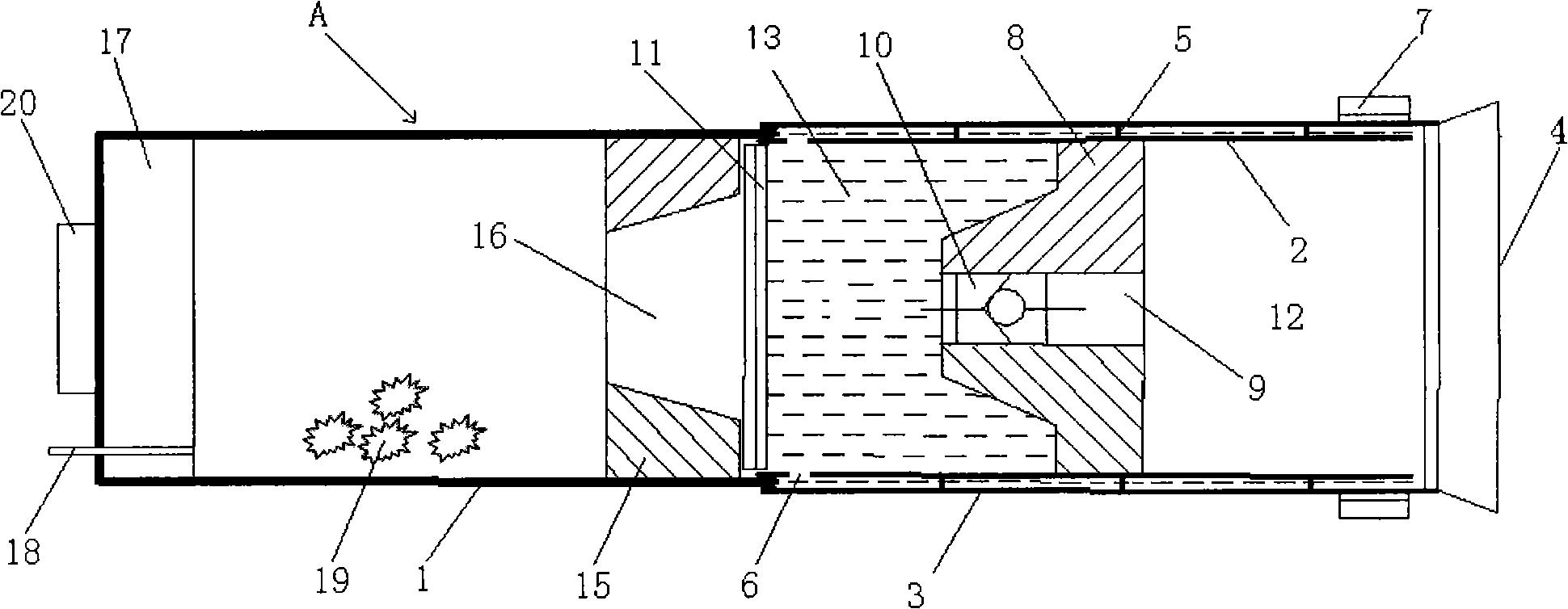

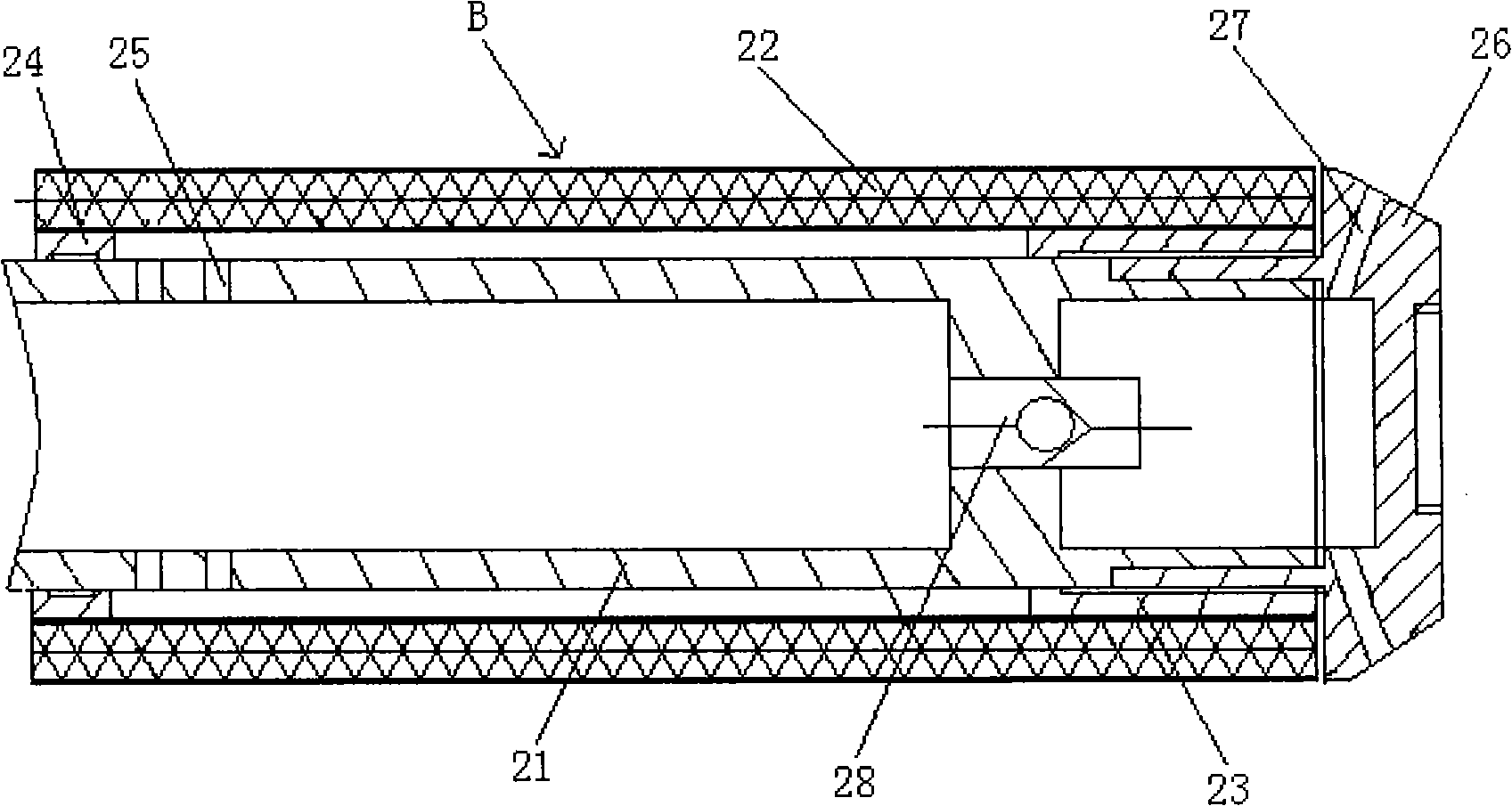

[0020] As shown in Fig. 1, the sampling device of the present invention includes a coal seam sampler A arranged at the front end and an expandable capsule hole sealer B arranged at the rear end.

[0021] Such as figure 2 As shown, the sampler A of the present invention includes a vacuum tube 1 , an inner tube 2 , an outer tube 3 and a sampling drill 4 . The rear end of the inner tube 2 is screwed on the inner wall of the front end of the vacuum tube 1, the rear end of the outer tube 3 is sleeved outside the inner tube 2 and screwed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com