Method and apparatus in connection with laser use

A laser, laser source technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of uneven intensity distribution in the processing direction, changing the nature of the problem, and unsuccessful provision, etc., to achieve excellent surface finishing and cleaning Processing, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

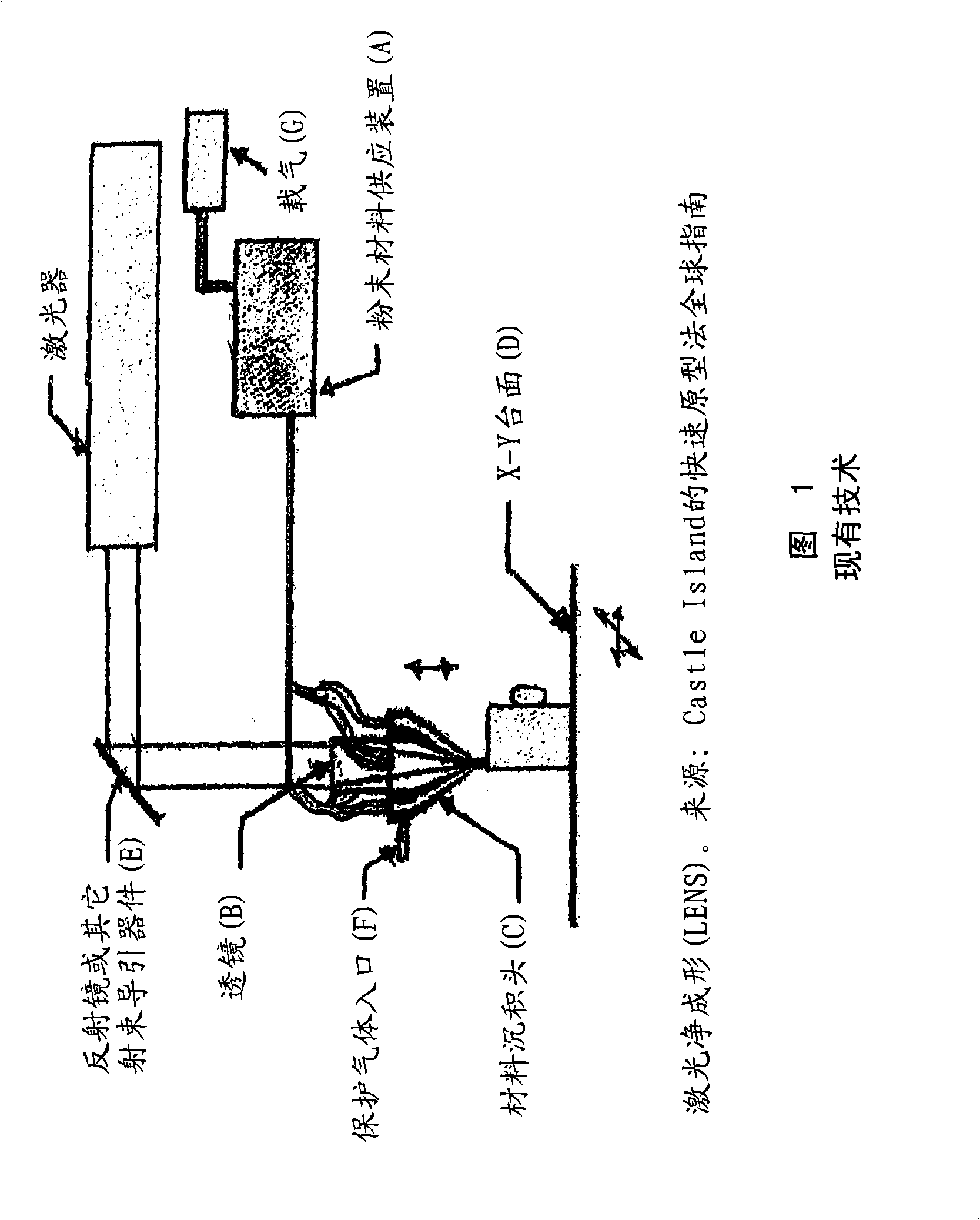

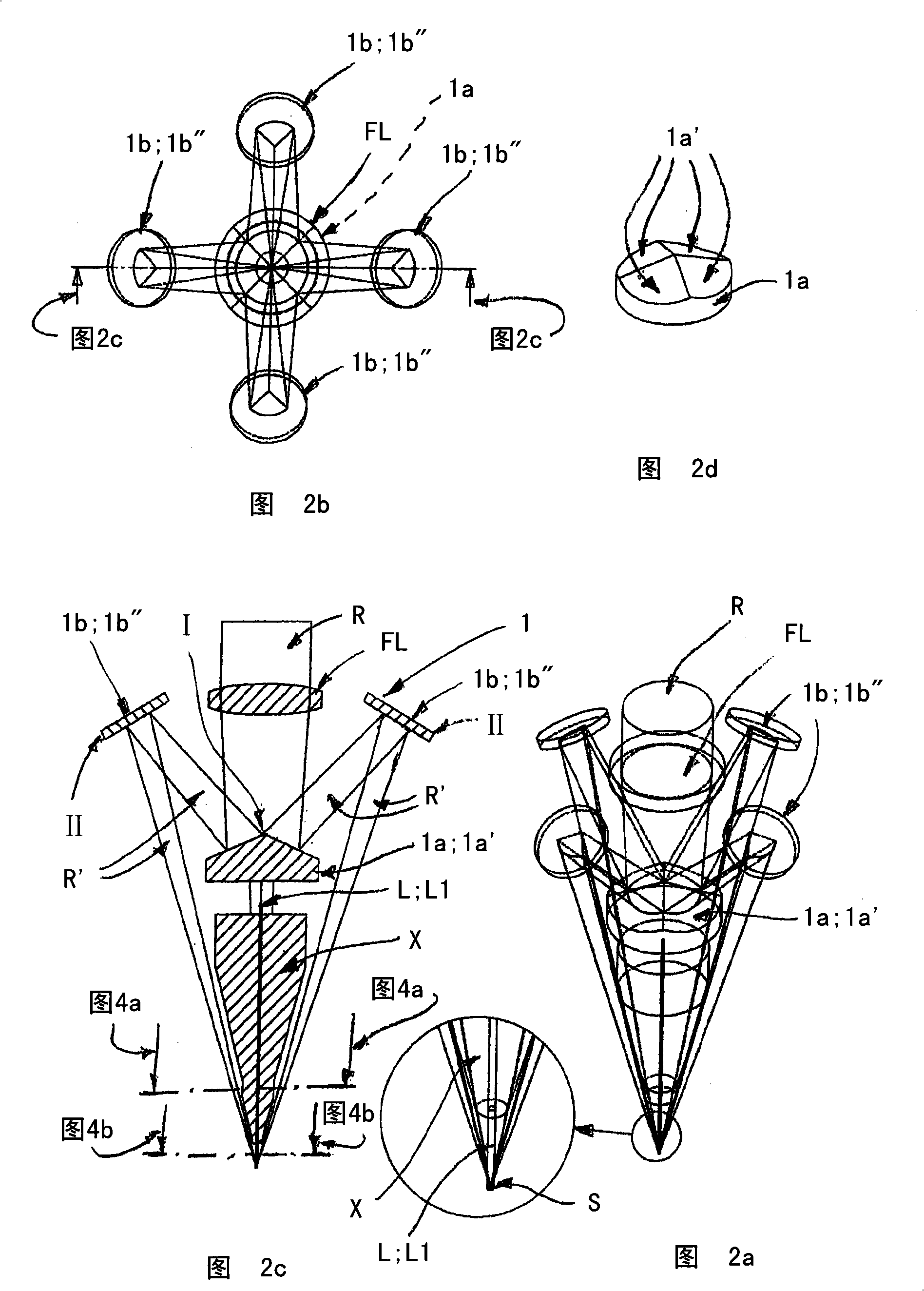

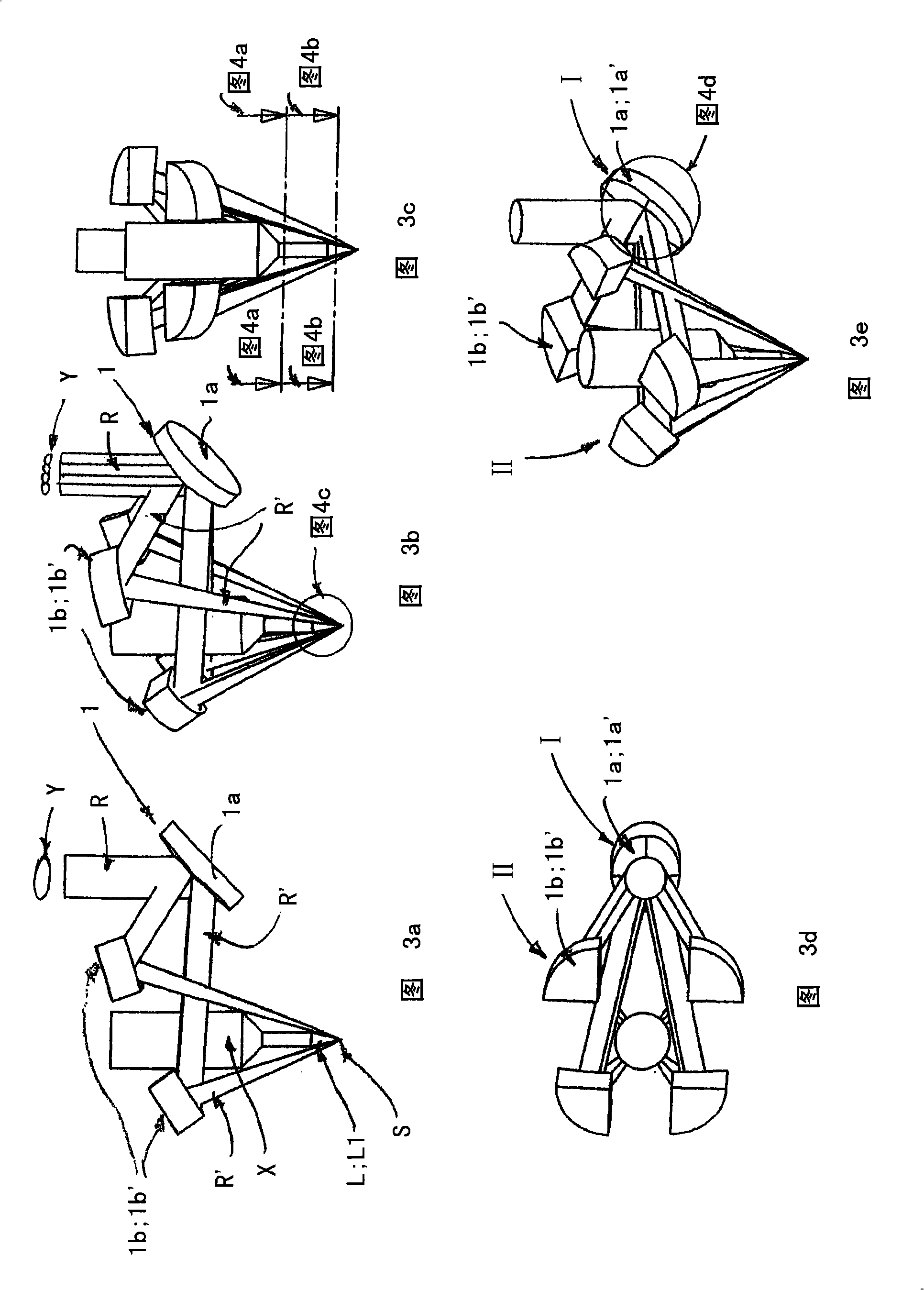

[0020] The invention relates to a method in connection with the use of lasers, in which one or more laser beams R emitted by one or more laser sources Y are focused on the fusion site S by means of a beam-guiding element 1, at At the fusion point, the filler material L supplied to the fusion point is melted and thus used in particular to carry out welding, coating, component manufacturing and / or similar processes. The filler employed comprises substantially solid elongated filler material L; L1, such as welding wire or similar material, which is passed through a delivery system X relative to a single strand focused on the fusion site as shown in Figure 3a. A laser beam or a plurality of laser beams focused on the fusion site as shown in FIG. 3 b is supplied to the fusion site S in a central manner. The divergence I of one or more laser beams R is produced by the multi-segment mirror 1a, in particular to maintain the symmetry of the intensity distribution of said laser beams, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com