Efficient concrete waste recovering process and device thereof

A technology for concrete waste and recycling equipment, which is applied in clay preparation devices, chemical instruments and methods, cement mixing devices, etc., which can solve the problems of large cleaning water consumption, waste of power, clear water, and large power loss, and achieve low cleaning water consumption , high water utilization rate and low power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

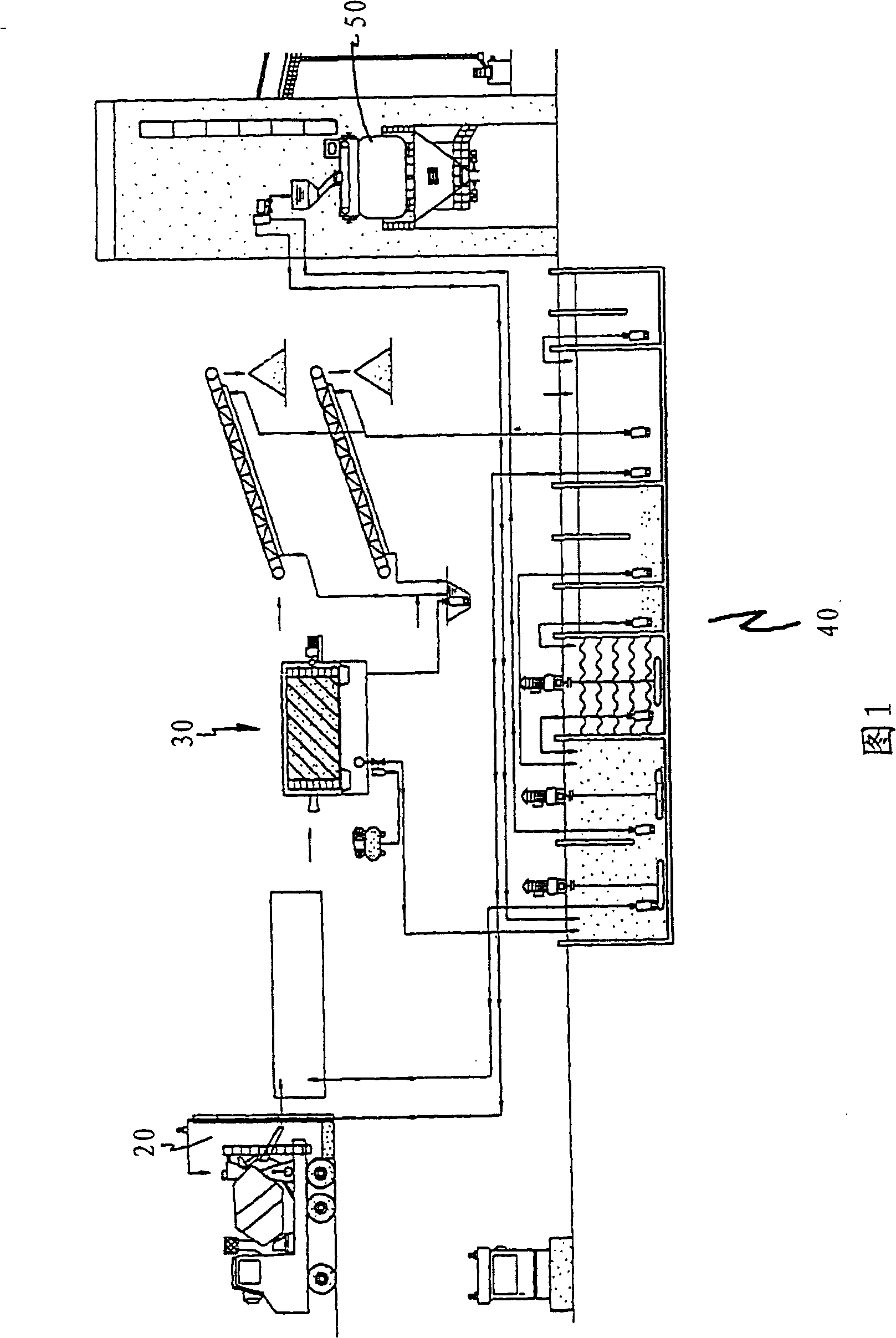

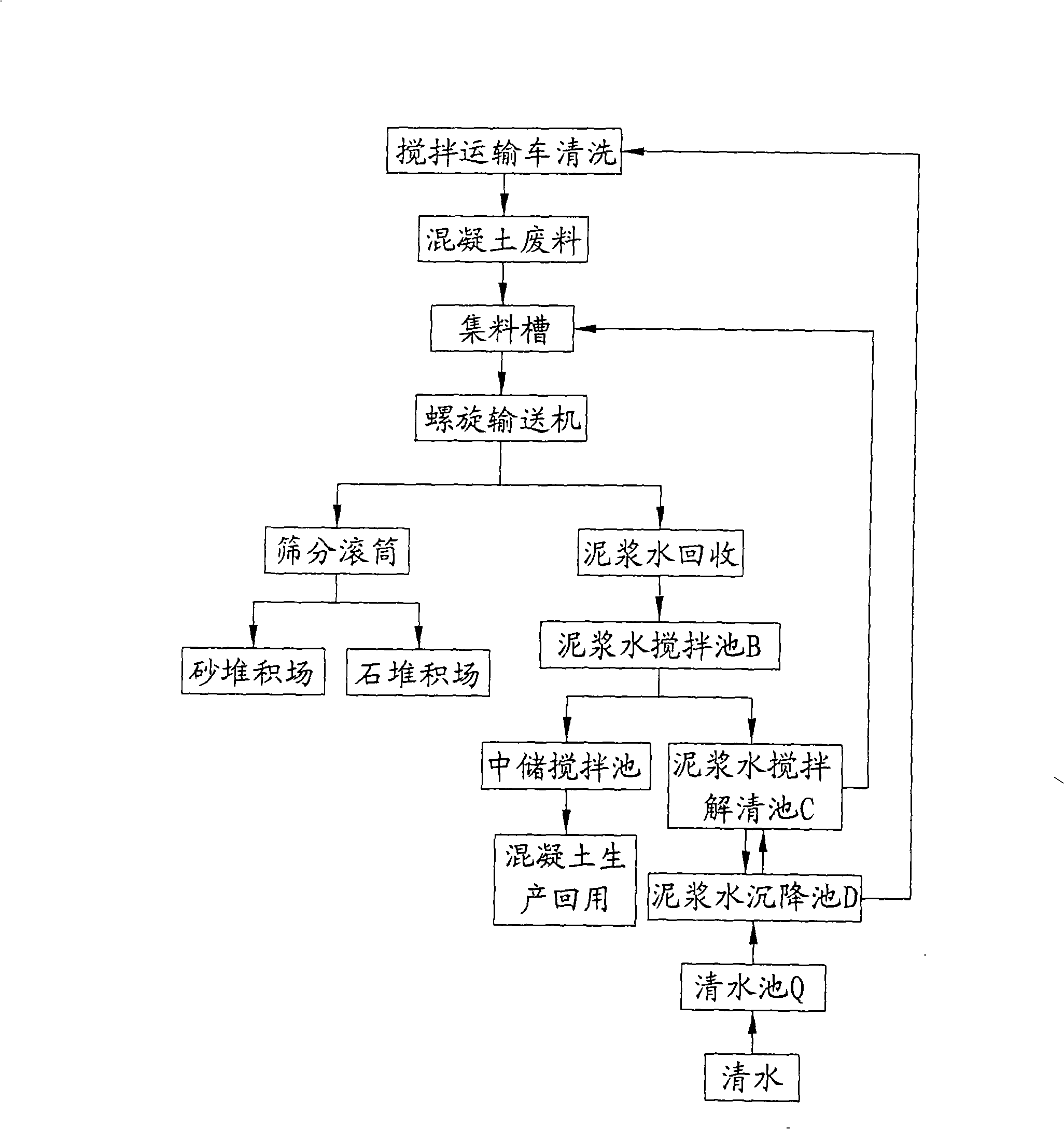

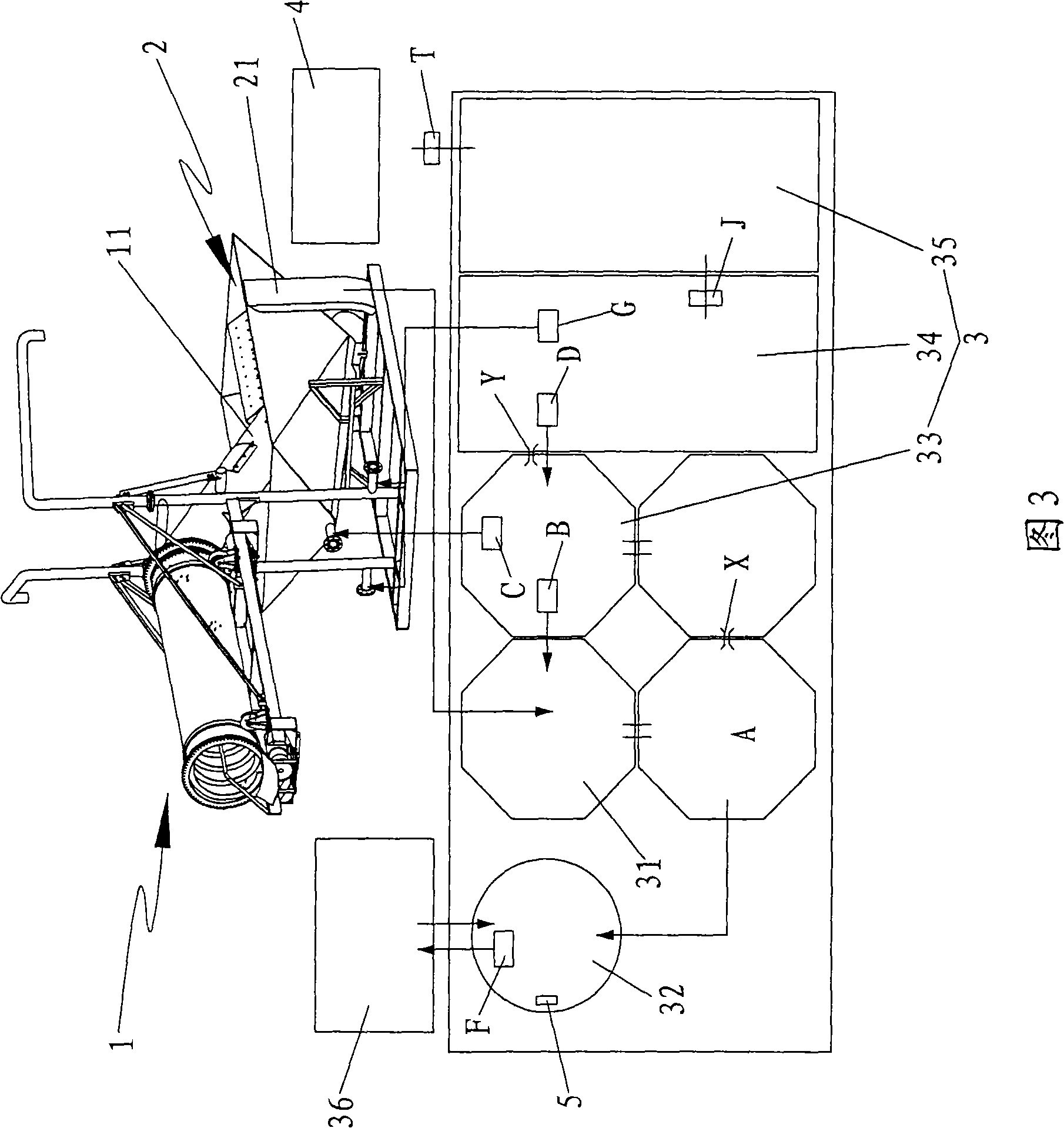

[0028] Such as figure 2 Shown, the present invention is a kind of efficient concrete waste recycling method, and it comprises the following steps:

[0029] (1) Clean the mixer truck;

[0030] (2) Unload the waste concrete to the collection tank;

[0031] (3) washing waste concrete by agitated water;

[0032] (4) Send the cleaned sand and gravel to the sand and gravel separation system (screening drum) through the screw conveyor to separate the sand and stone that meet the raw materials;

[0033] (5) At the same time, the cleaned mud water is recycled and sent to the mud water mixing tank of the water circulation system. After stirring, the mud water is sent to the middle storage mixing tank, and the precipitated mud water is sent to the concrete mixing equipment; The separated water is sent to the collecting tank in step (2) for cleaning waste concrete; the clear water filtered in the mud water settling tank is pumped as the water for cleaning the mixer truck in step (1). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com