Full-automatic air injection proofing press

A sample weaving machine, fully automatic technology, applied in looms, textiles, textiles and papermaking, etc., can solve problems such as difficulties in weaving samples, achieve the effects of reasonable design of operation functions, time saving, and precise control of sample quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

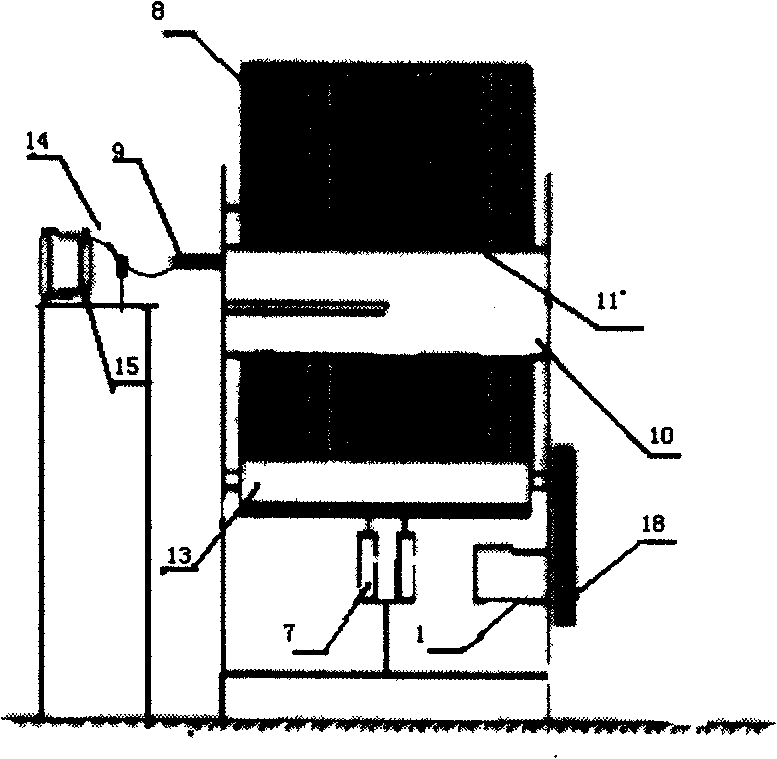

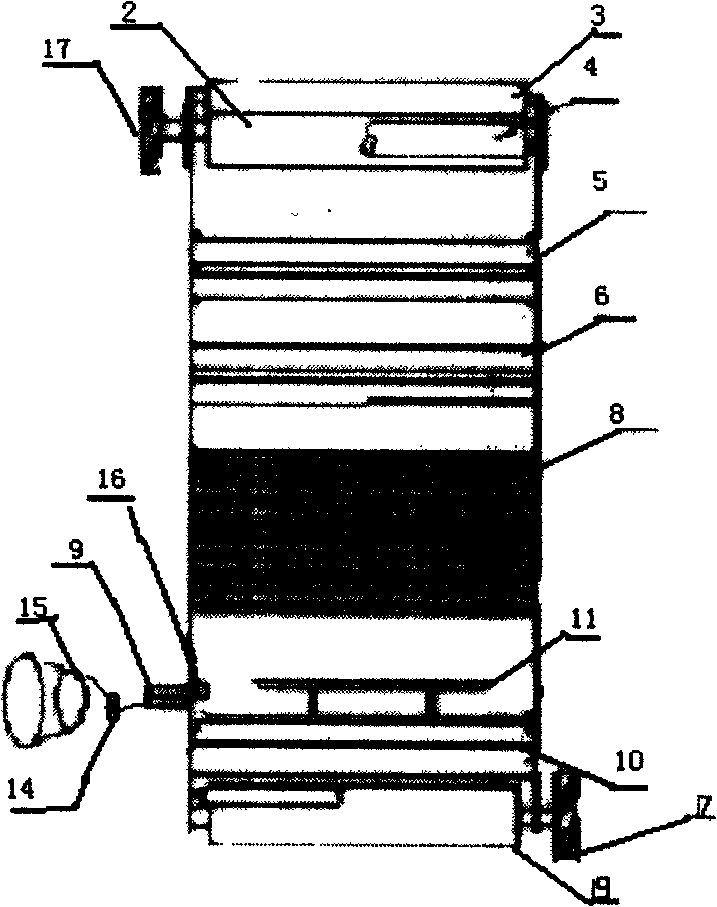

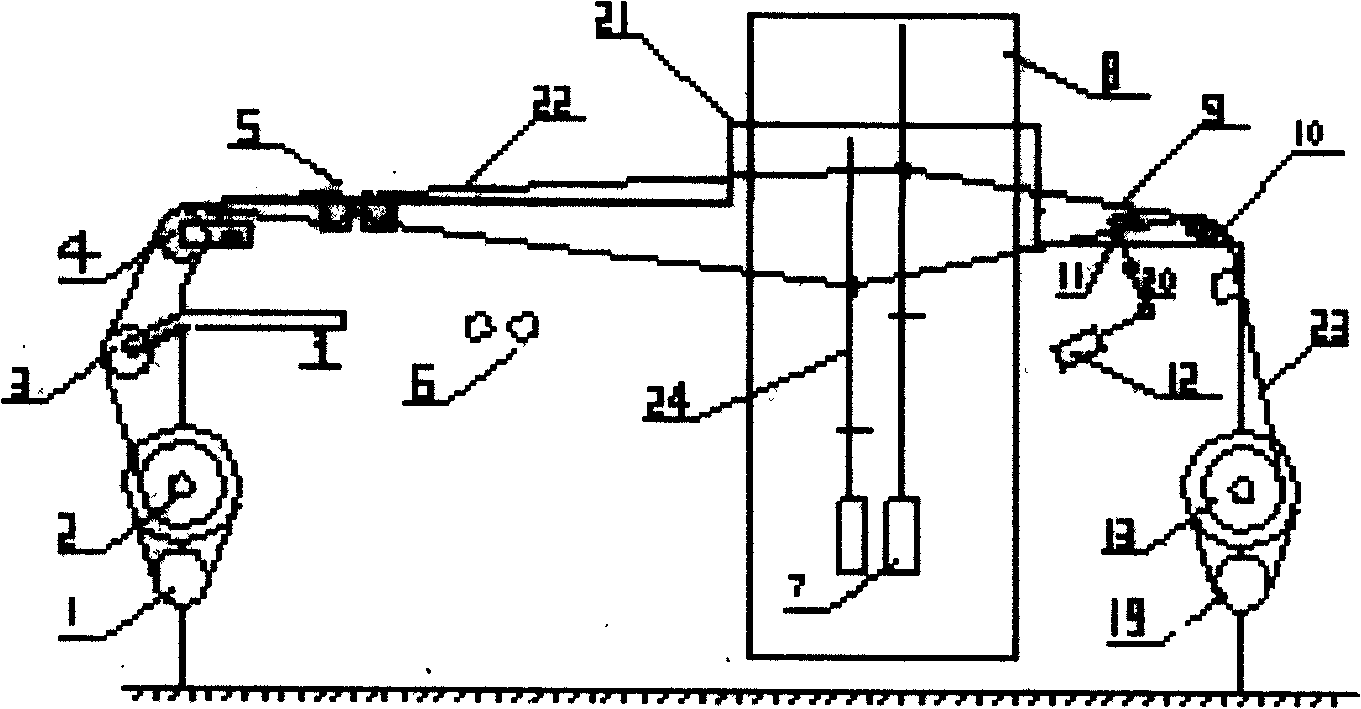

[0013] 1. Mechanical structure:

[0014] On the frame (21) of the sample loom, a heald lifting mechanism (8), a weft insertion mechanism, and a weft beating mechanism are installed, and the weft insertion mechanism and the beating mechanism are respectively positioned at the front portion of the weaving sample machine. In the weft insertion mechanism, the weft insertion Nozzle is positioned at the left side of frame, and in beating-up mechanism, beating-up cylinder (12) utilizes lever (20) to be connected with steel sley (11), and the middle part of lever (20) is hinged on the frame (21), steel The sley (11) is positioned at the shed opening of the sample loom.

[0015] The heald lifting mechanism (8) is located in the middle of the sample loom, and a plurality of heald frames (24) that can move up and down are placed in the heald frame groove frame, and the bottom of the heald frame (24) is connected with the piston rod of the open cylinder (7); At the rear of the sample loo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com