Multi-test seat test station having in-turn arranged feeding section, test section and discharging section

A technology for testing machines and testing areas, which is applied to the testing of individual semiconductor devices, components of electrical measuring instruments, and electrical measurement. It can solve problems such as no simplification of the moving process, inability to improve the overall effect alone, and a sharp increase in manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

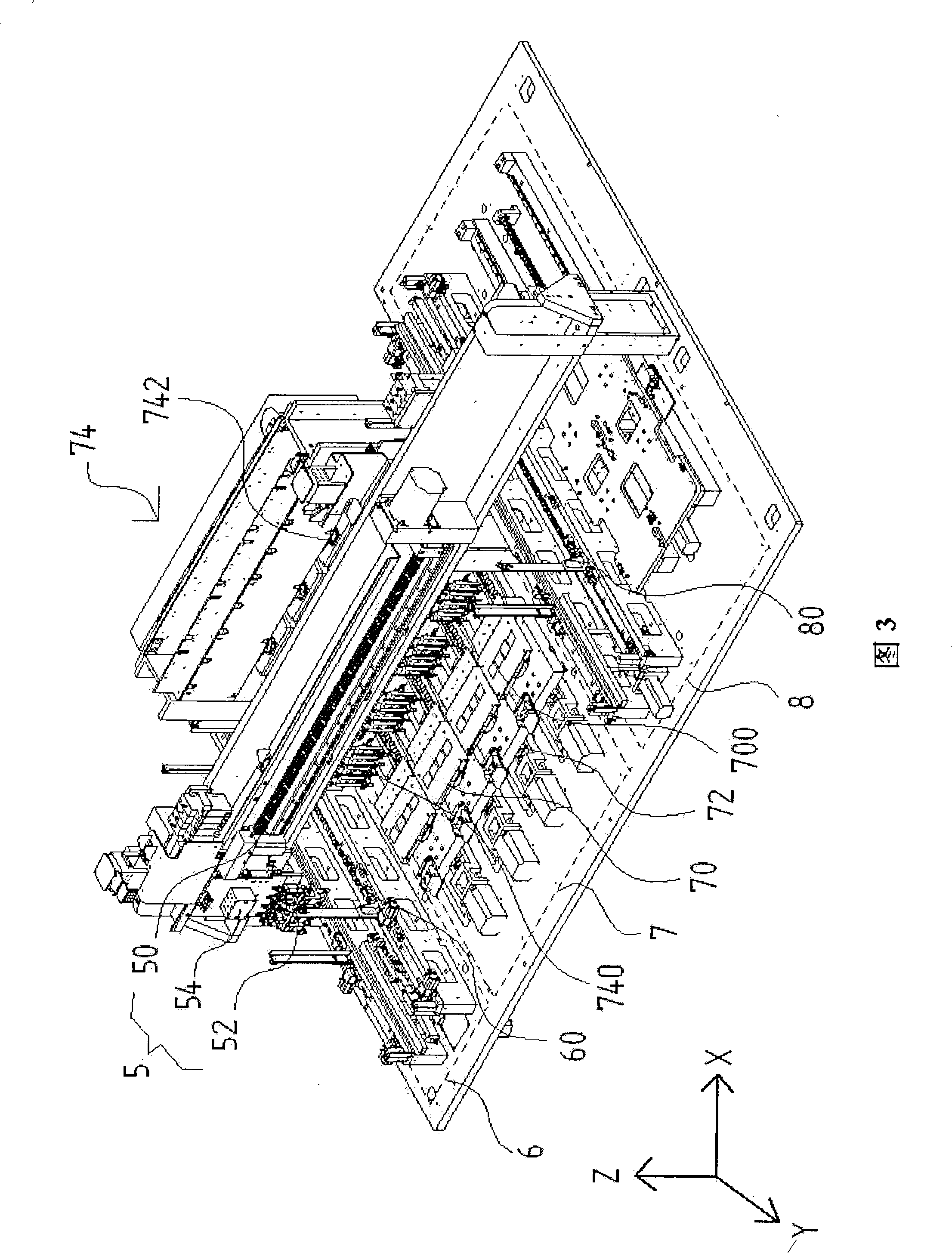

[0052] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the accompanying drawings. For convenience of description, the feeding device, the discharging device and the driving device 72 of the detection machine of the present invention are all taken as an example of a screw.

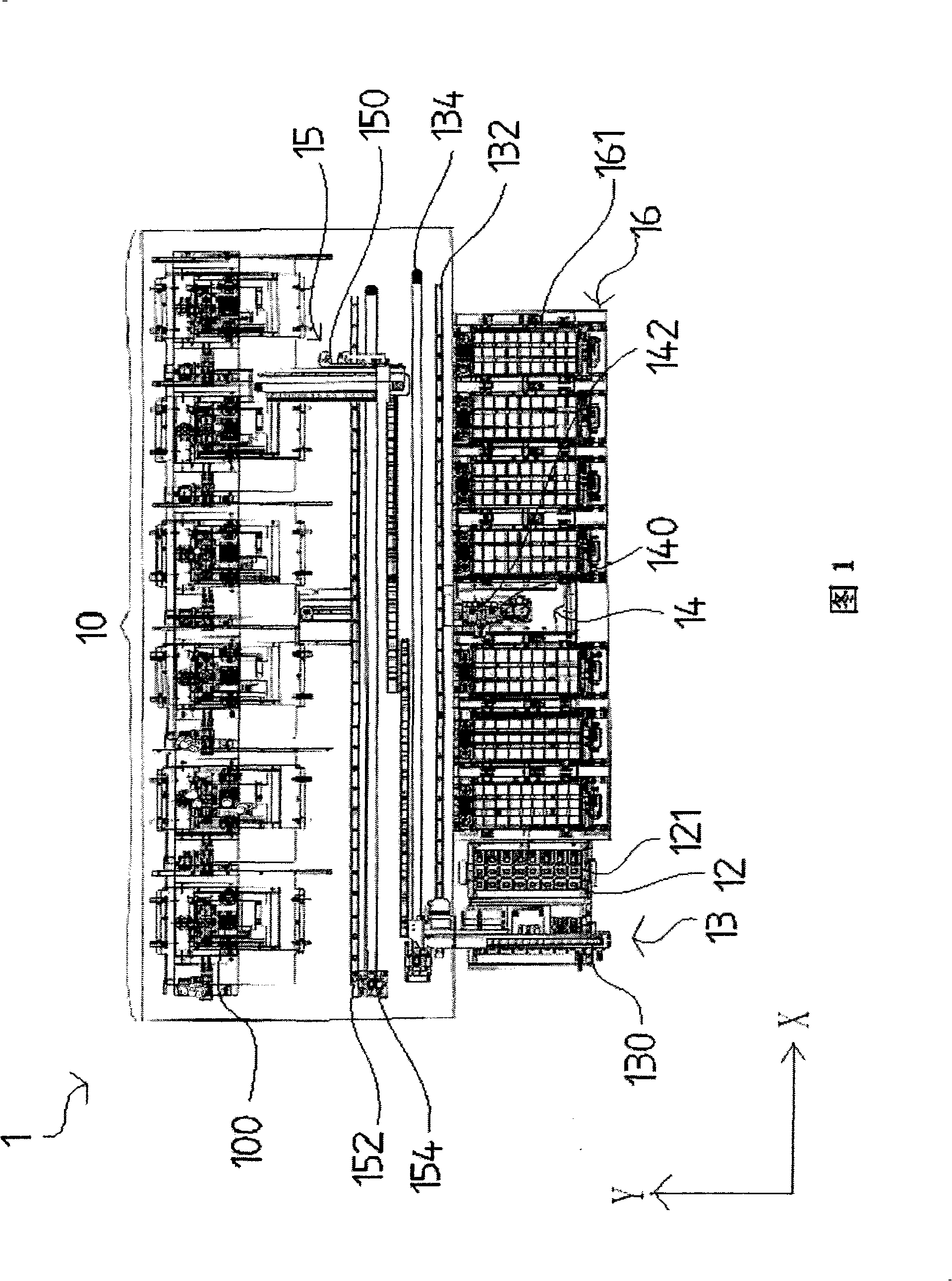

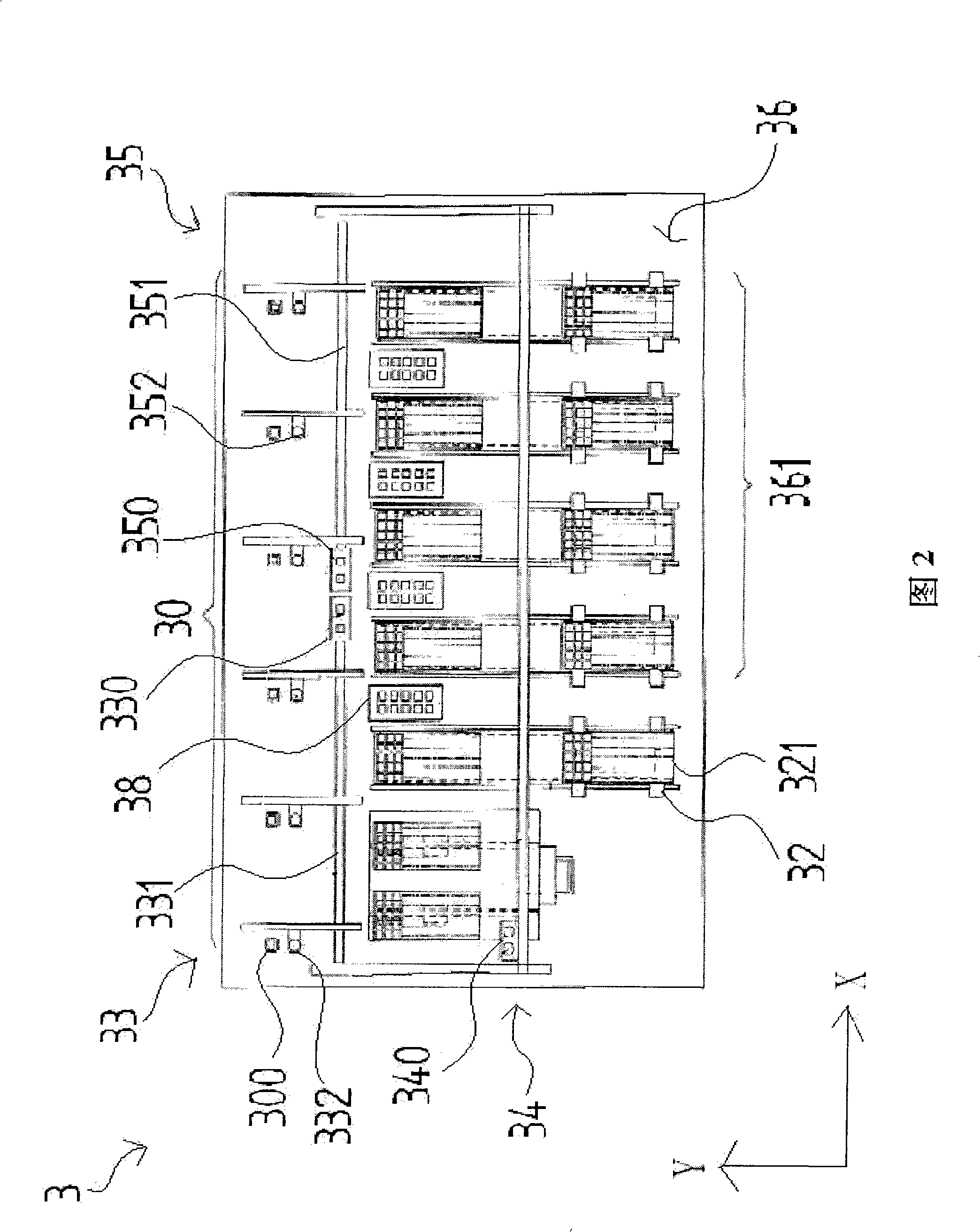

[0053] As shown in FIGS. 3 to 8 , the machine is mainly divided into a feeding area 6 , a testing area 7 and a discharging area 8 . Wherein, the feed area 6 is provided with a feed screw 60; the test area 7 includes a plurality of test bases 70 respectively forming a plurality of accommodating grooves 700, a plurality of driving devices 72 and a test device 74 respectively corresponding to the test bases 70 , Leveling sensor 740 and leveling value display 76; , wherein the discharge area 8 includes a discharge screw 80; carrying the mobile device 5 and the pick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com