Heating power supply device of man-made diamond pressing machine

A technology of artificial diamond and heating power supply, applied in the direction of output power conversion devices, electrical components, high-efficiency power electronics conversion, etc., can solve the problems of uneven current distribution, migration and accumulation of positive and negative ions, etc., to achieve elimination of accumulation, long conduction time, The effect of improving quality and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

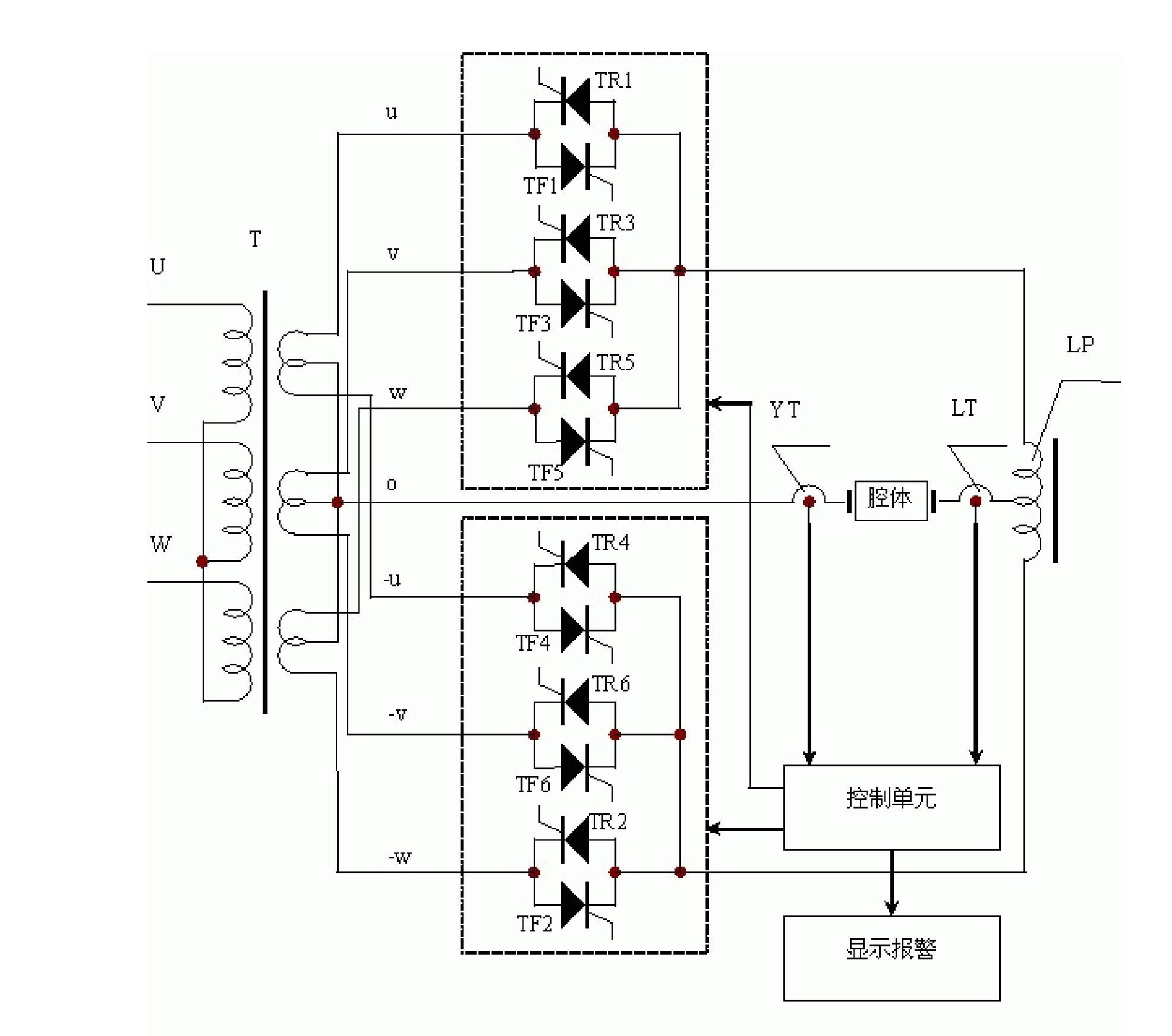

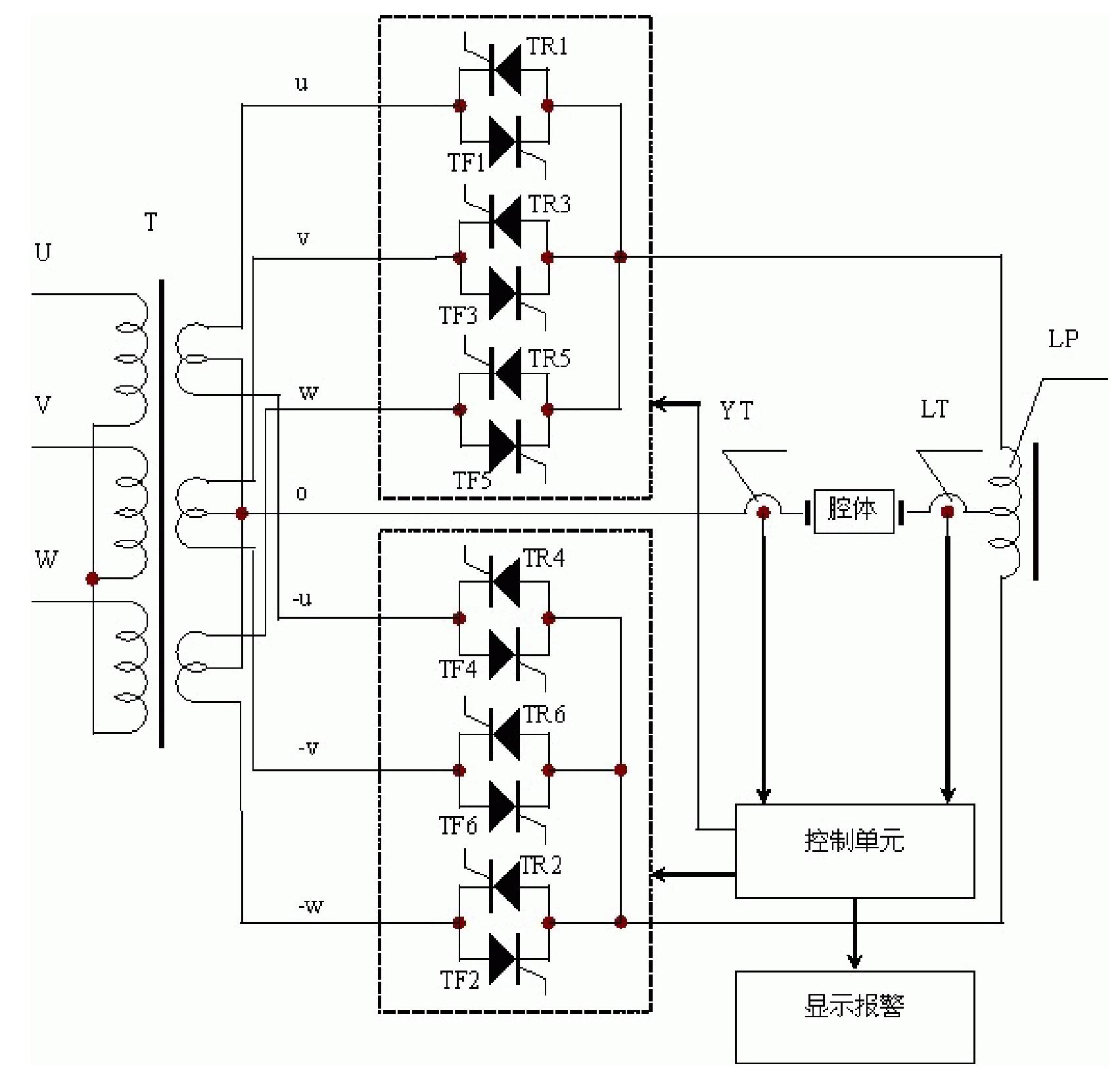

[0016] Examples of heating power supply devices for artificial diamond presses of the present invention figure 1 As shown, the three-phase 50Hz, 380V mains is directly connected to the primary winding of the three-phase power frequency transformer T, and the secondary of the transformer T has two windings with the same number of turns per phase, which are connected into a double reverse star circuit. The midpoints of the shaped circuit are connected together (point o), and connected to one end of the electrode of the synthetic diamond press chamber. 6 forward rectification thyristors TF1~TF6 and balance reactor LP form a forward current double reverse star phase-controlled rectification circuit, and 6 reverse rectification thyristors TR1~TR6 and balance reactor LP form a reverse current double reverse star phase-controlled rectification circuit circuit. The u phase of a star circuit on the secondary side of the transformer T is connected to the anode of the first forward rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com