Device and method for processing meat carcass

一种电压、时段的技术,应用在通过电处理肉软化、屠宰、应用等方向,能够解决延长熟化时间等问题,达到实现先进先出系统、稳定温度控制、减少活细胞数的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

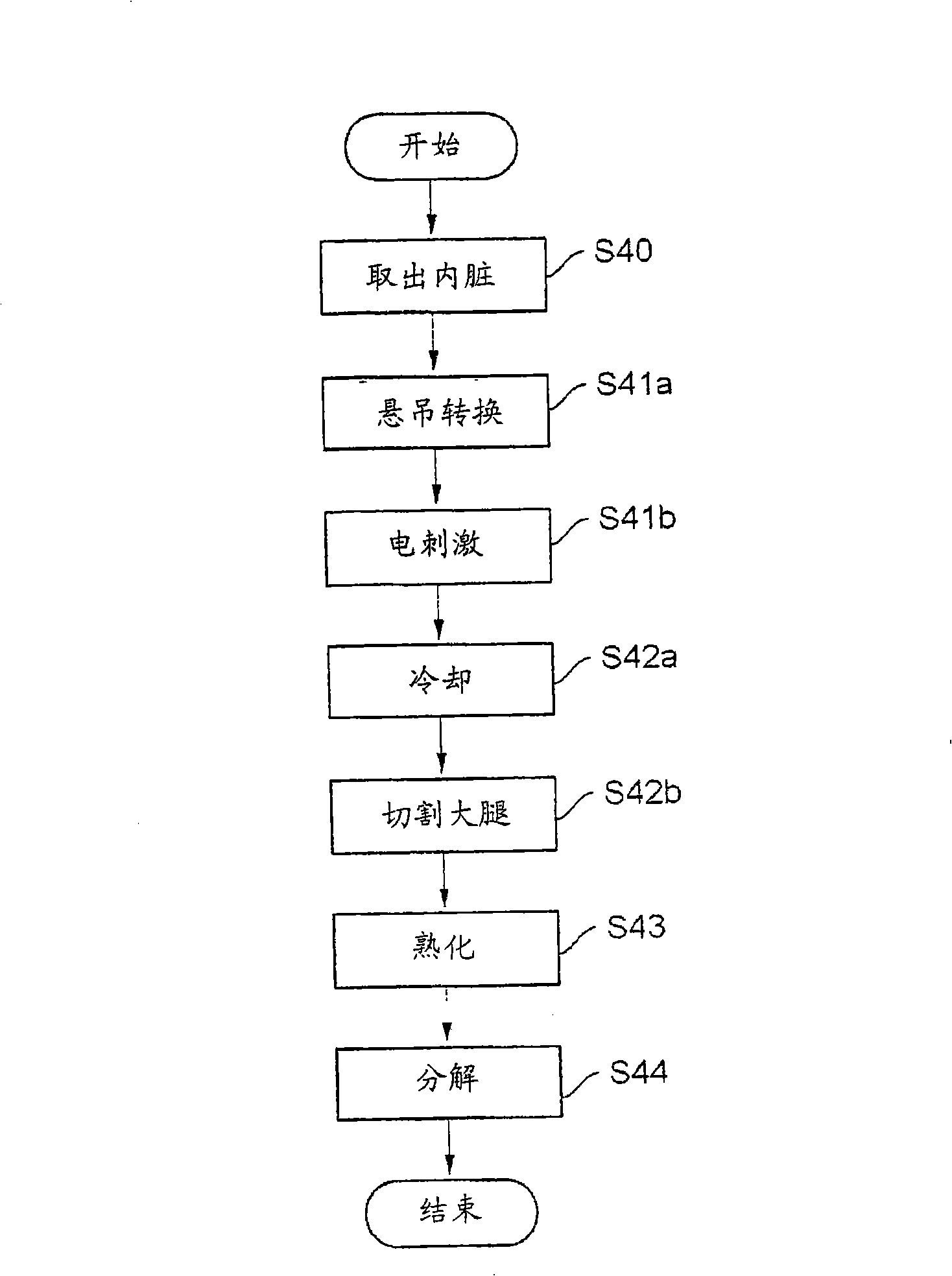

[0040] First embodiment (handling method for slaughtering animals)

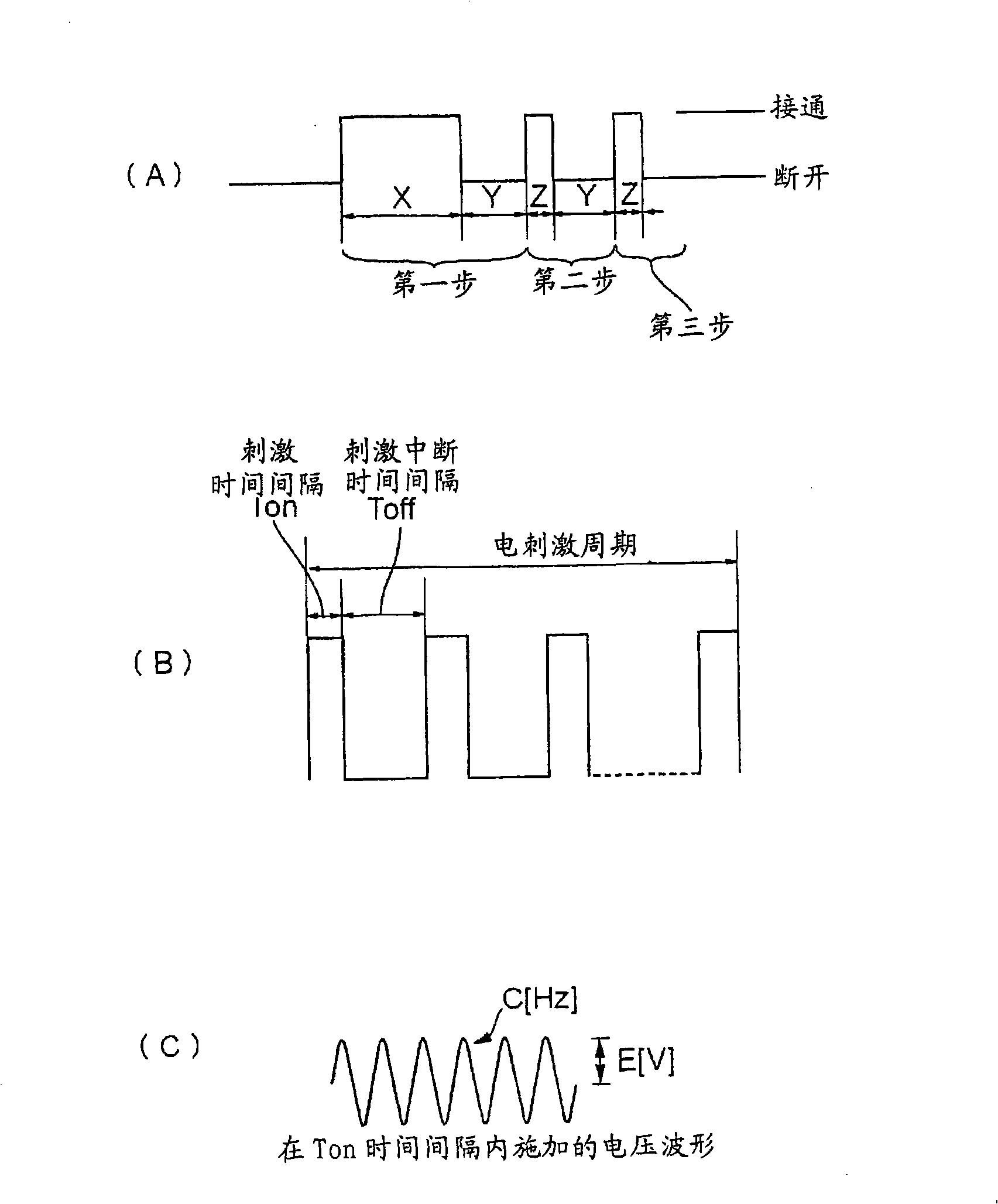

[0041] In this embodiment, the above-mentioned conventional processing steps are adopted, and the voltage waveform is changed in the electrical stimulation application step S41b, and by this change, the time required for maturing the slaughtered animal can be shortened from about four hours to half a day required by the conventional processing method to about two hours, and can obtain the same results as traditional methods. The first embodiment of the treatment method of the present invention includes a transporting step and an electrical stimulation applying step. The transporting step is for transporting a carcass that has undergone the treatment of the evisceration step S40 and is in a state before and during the onset of stiffness, wherein the carcass is in the state of stiffness. Applying an electrical stimulation voltage having a plurality of voltage application cycles of different application duration...

no. 2 example

[0045] Second embodiment (processing method for slaughtering animals)

[0046] In this embodiment, a second electrical stimulation application step is also provided after the cooling step (low temperature cooling step) S42a and before the thigh cutting step S42b. That is, this embodiment of the processing method includes the step of removing the internal organs, the first electric stimulation application step of applying electric shocks to the slaughtered animals in the state before the onset of stiffness and the state of the stiffness process, the low-temperature cooling step, and the cooling step after the cooling step. A second electrical stimulation application step of applying an electric shock to the slaughter animal. The electrical stimulation voltage application pattern in each electrical stimulation application step can be determined to optimize the electrical stimulation effect.

no. 3 example

[0047] The third embodiment (processing method for slaughtering animals)

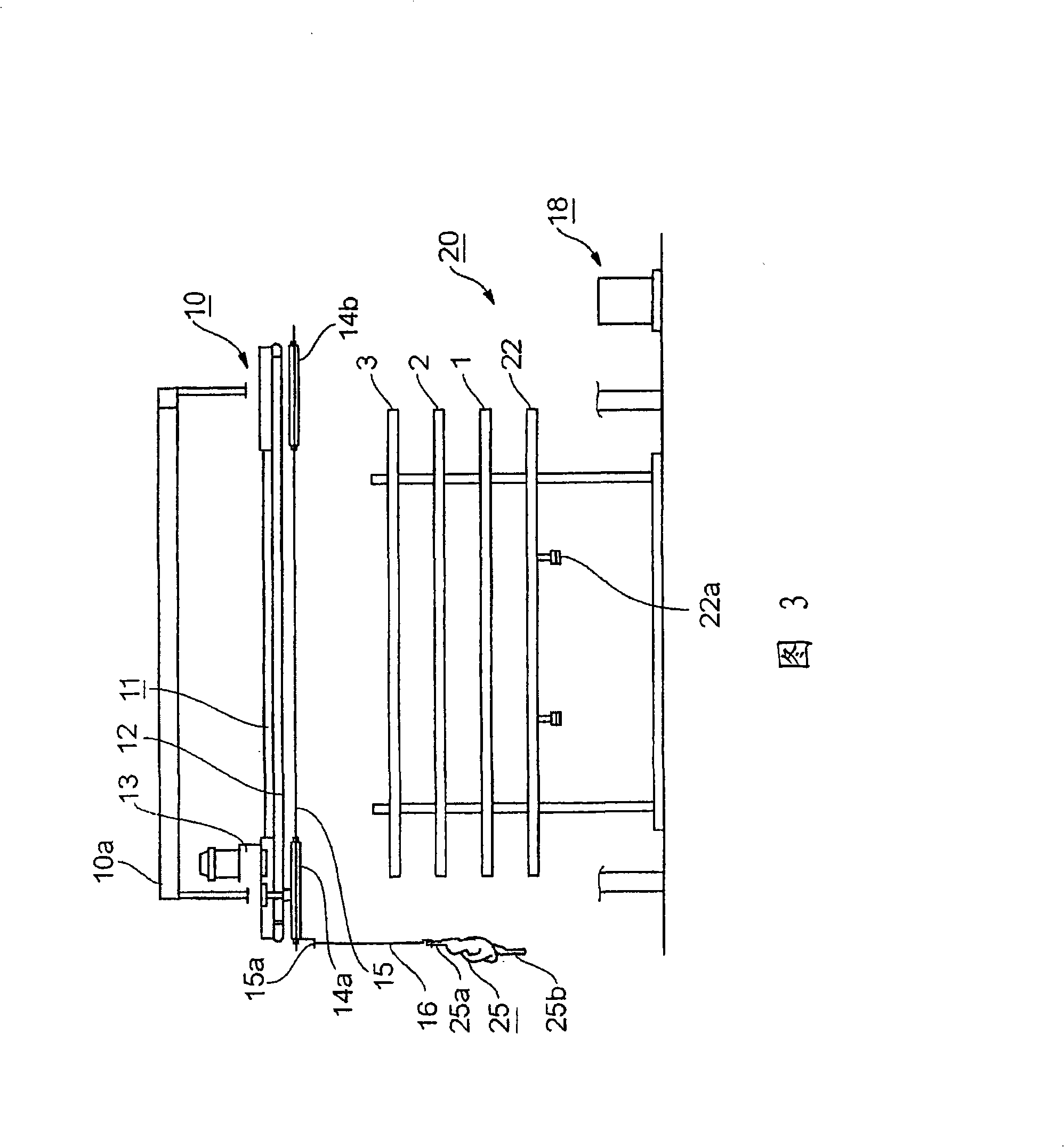

[0048] FIG. 3 is a front view of the slaughter processing device of this embodiment, which includes a transfer conveyor 10 , a voltage applying section 20 , and an electric control section 18 . Transfer conveyor belt 10 comprises conveying mechanism 11, and this transfer conveyer belt comprises frame 10a, is positioned at frame 10a horizontal circular guide rail 12, conveying chain 15 in the upper part of frame 10a, and it is used for conveying a plurality of being coupled on the guide rail and guided by guide rail 12. Roller stand (not shown in Fig. 3), driving sprocket 14a, driven sprocket 14b and driving gear motor 13, and a plurality of shackles 16, each shackle is used to clamp the pin 25a of slaughtering animal 25 , a shackle is detachably coupled to each of the hooks 15 a coupled to the conveyor chain 15 .

[0049] Figure 4 It is the front view of the right side of the slaughtering animal hand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com