Phase-change adsorption air dehumidifier

An air dehumidification and phase change technology, applied in combustible gas purification, combustible gas purification/transformation, filter regeneration, etc., can solve the problem of reducing the water vapor potential difference between the adsorbent and air, low dehumidification effect, and increased outlet temperature, etc. problem, achieve the effect of improving dehumidification effect, improving dehumidification efficiency and preventing overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

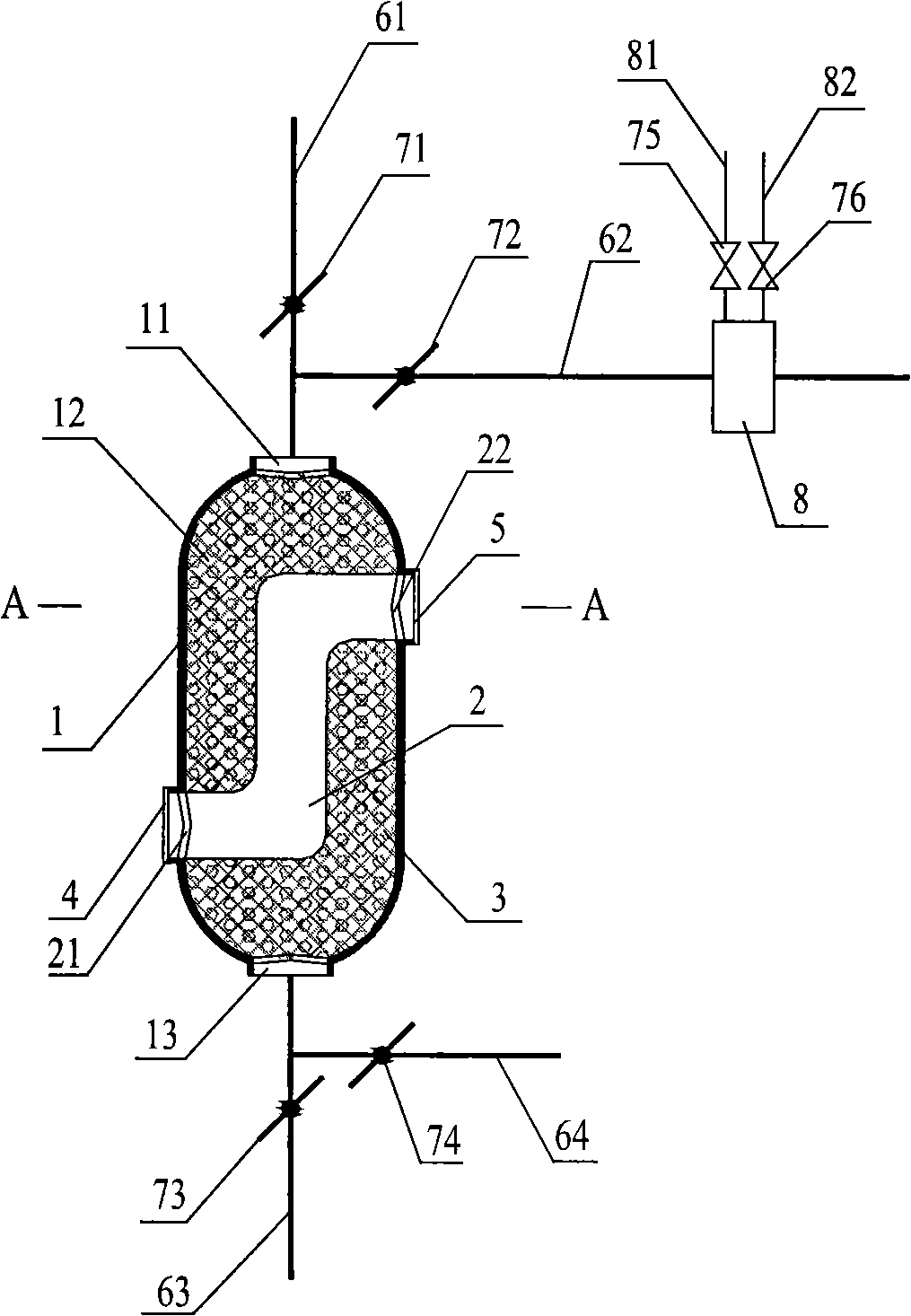

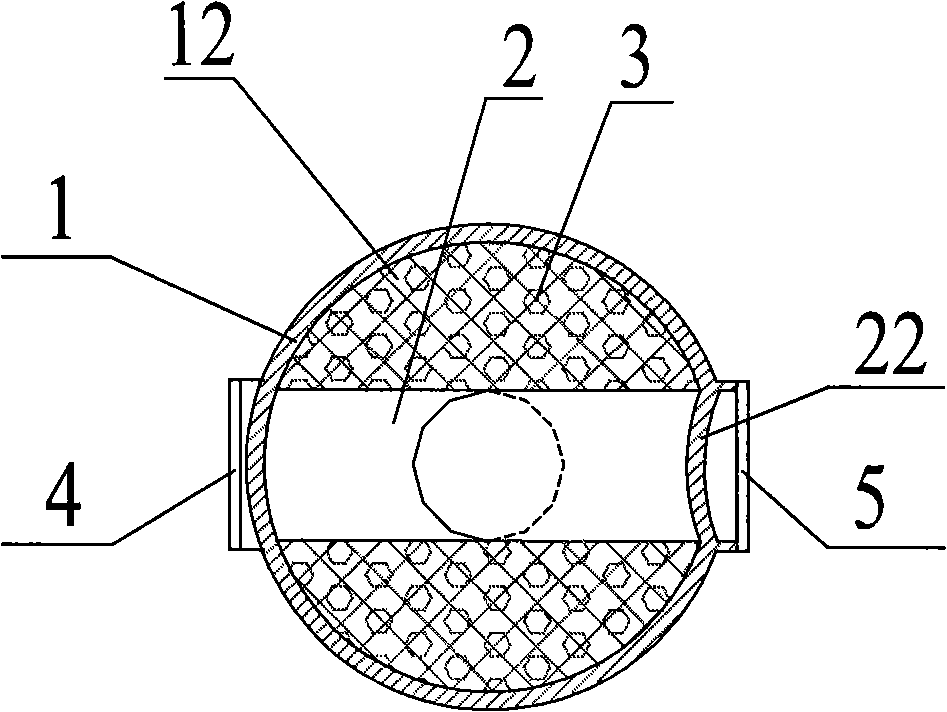

[0021] figure 1 with figure 2 In combination, a phase change adsorption air dehumidification device is provided, which includes a phase change adsorption reactor 1 with a cavity 12 inside, and the top opening 11 and the bottom opening 13 of the phase change adsorption reactor 1 are in communication with the cavity 12 . The processed air outlet pipe 61 is sealed and connected with the top opening 11, and a cut-off valve I71 is provided on the processed air outlet pipe 61. One end of the regeneration air inlet pipe 62 is sealed and connected with the top opening 11, and the other end is connected with the regeneration air heater 8, and a shut-off valve II 72 is provided on the regeneration air inlet pipe 62; The heat medium inlet pipe 81 and the heat medium outlet pipe 82, in order to save energy, the regenerative air heater 8 selects the heater provided by the solar heat collection system; the heat medium inlet pipe 81 is provided with a stop valve V75, Outlet pipe 82 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com