Yarn guiding mechanism on textile machines

A technology of reciprocating motion and textile machine, which is used in transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of inability to adjust the lifting stroke of the reciprocating rod, vibration, and short service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

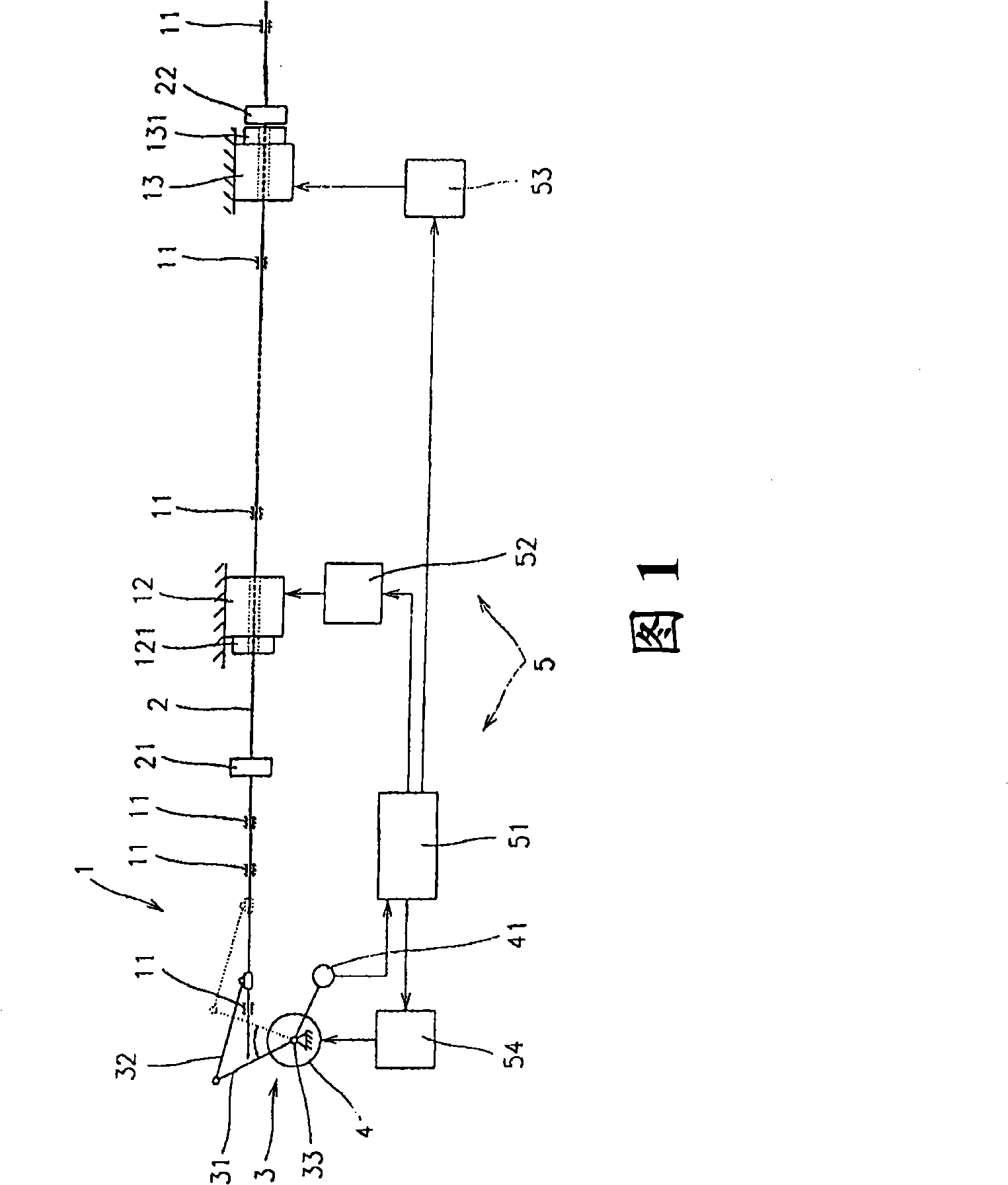

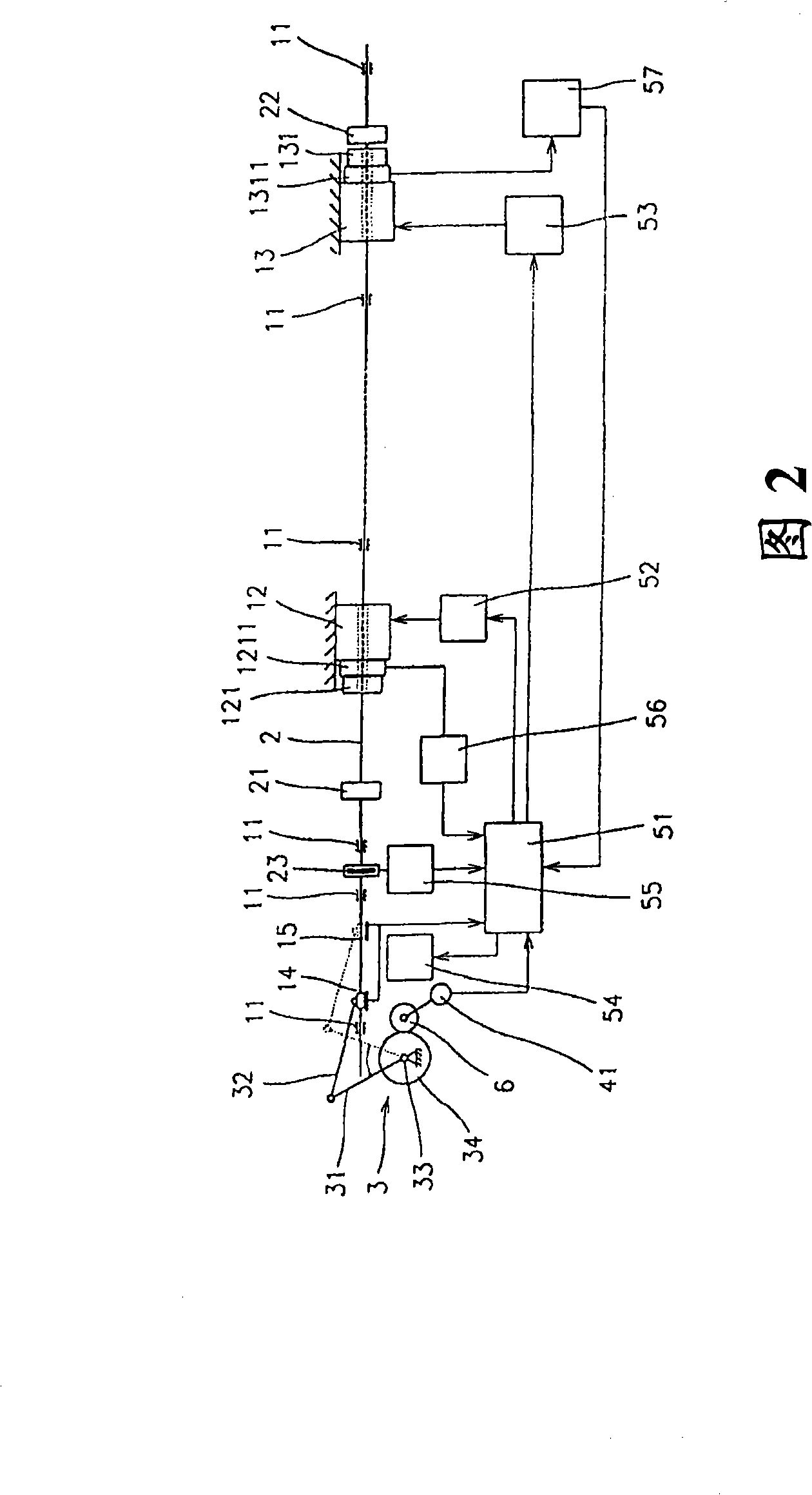

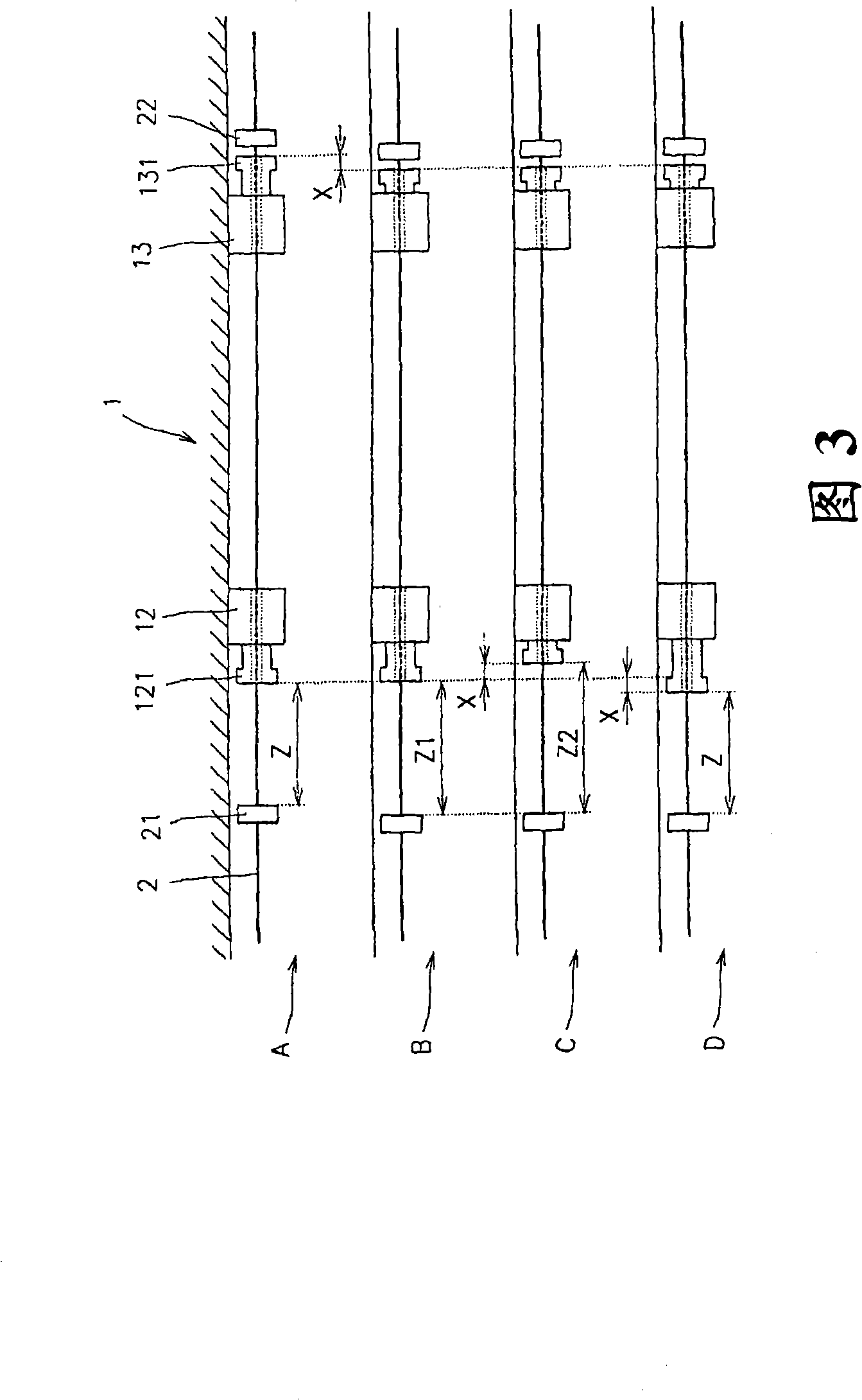

[0063] A basic embodiment of the device according to the invention is shown in FIG. 1 . On the frame 1 of the textile machine, a reciprocating rod 2 is installed via a guide device 11 . The reciprocating rod 2 is driven by an eccentric crank mechanism 3 comprising a crank 31 and a connecting rod 32 . The crankshaft 33 is concentrically connected to the output of the drive servo motor 4 equipped with a position sensor 41 . Moving magnets 21 and 22 are fixedly connected to the reciprocating rod 2 . On the frame 1 of the machine are connected linear servomotors 12, 13, with static magnets 121 and 131 connected to their outputs. The reciprocating rod 2 freely passes through the openings on the static magnets 121, 131 and the linear servo motors 12, 13 (possibly on the outside of the linear servo motors 12, 13). The moving magnet 21 and the static magnet 121 form a co-operating couple like the moving magnet 22 and the static magnet 131 . The magnets are mutually distributed (mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com