Friction drive hoist cable brake and rope clamping device

A technology of friction hoist and steel wire rope, which is applied in elevators, hoisting devices, transportation and packaging, etc., can solve the skip accident in Xuzhou Quantai Mine in 1992, the tank falling accident in Zhangji Mine in Xuzhou in 1998, and the accident in 2001 In September 2005, there was a slipping rope falling tank accident in Xuandong Mine, Hebei Province. In September 2005, there was a bucket falling accident in Jincheng Changping Mine. In September 2006, there was a skip bucket accident in Jixi Chengzihe Mine, insufficient braking force, and wire rope contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

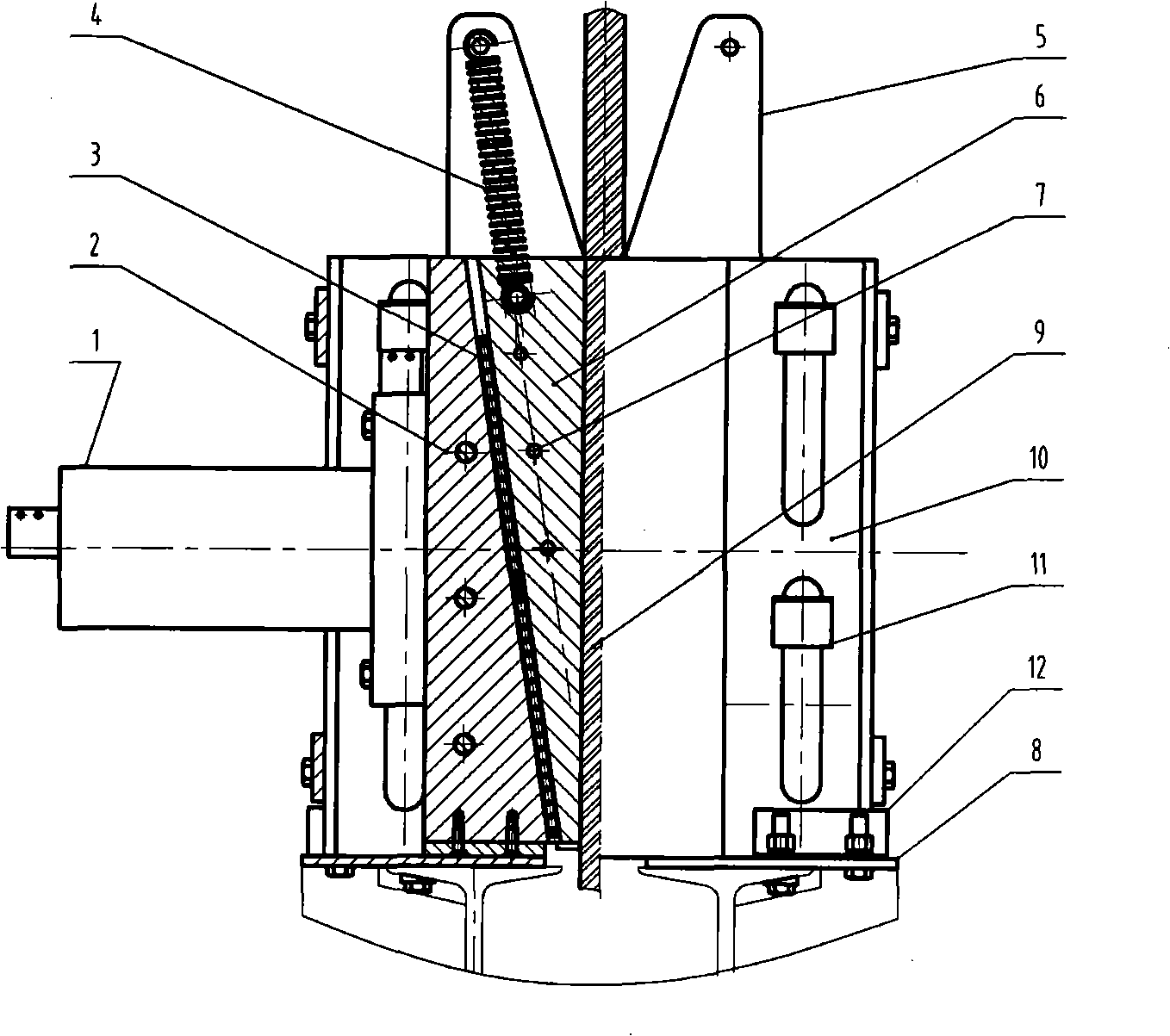

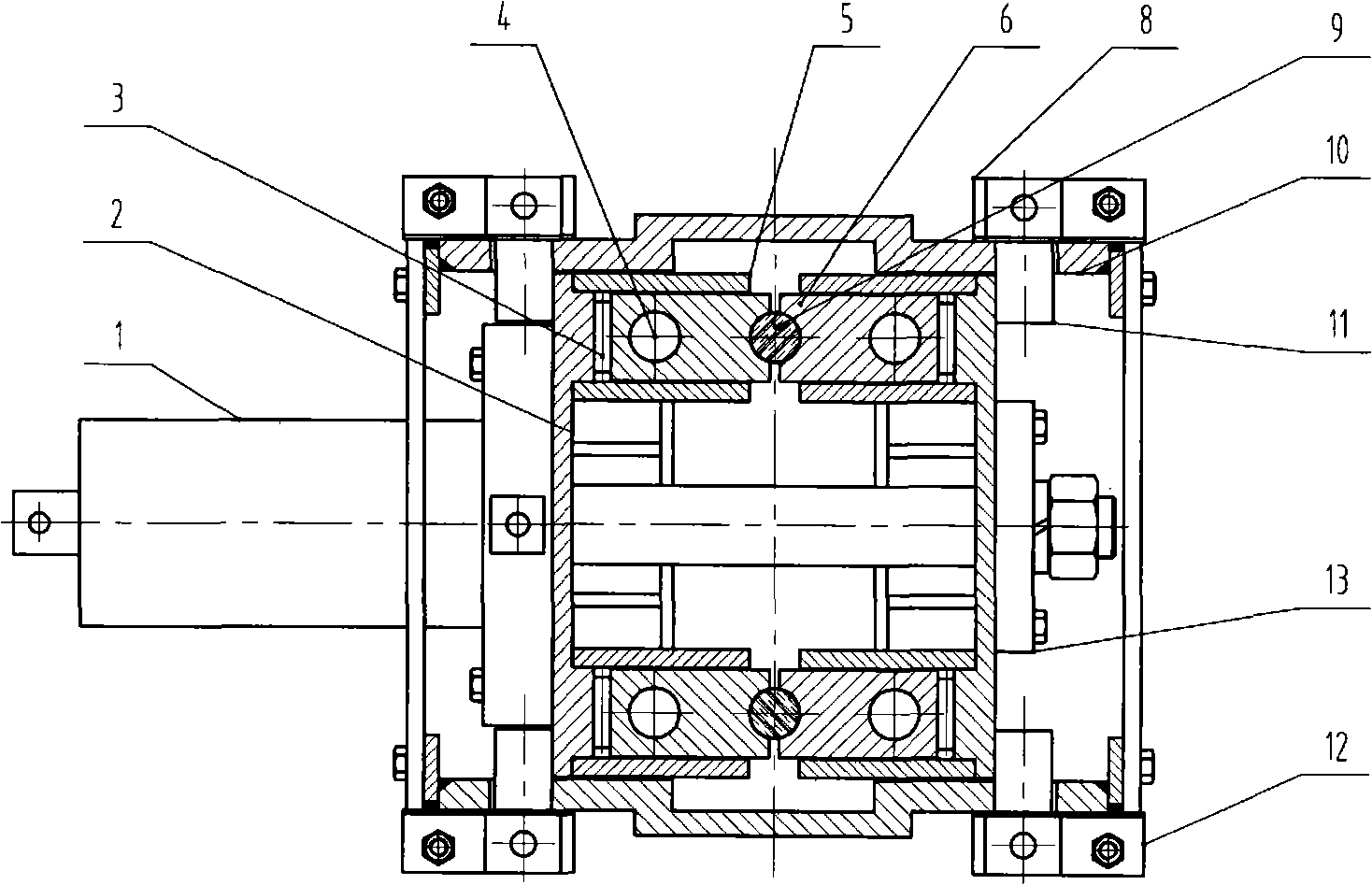

[0011] The friction hoist sliding rope braking and rope clamping device of the present invention is mainly composed of a brake cylinder 1, a rear push plate 2, a guide side plate 5, a wedge-shaped brake block 6, a sliding bottom plate 8, and a side pull plate 10. The moving block 6 is V-shaped and symmetrically arranged on both sides of the hoisting wire rope 9. The wedge-shaped brake blocks 6 symmetrically arranged on both sides of the hoisting wire rope 9 are two groups. The brake block 6 is integrated and wedged with the rear push plate 2, and the wedge-shaped brake block 6 is provided with a limit pin 7 that allows the wedge-shaped brake block 6 to slide downward along the guide groove. Between the wedging surfaces of the rear push plate 2 and the wedge-shaped brake block 6, a roller row 3 is installed to ensure the vertical movement of the wedge-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com