Hydraulic pump station for rail welding vehicle

The technology of a hydraulic pump station and a welding rail car is applied in the directions of fluid pressure actuating device, fluid pressure actuating system safety, fluid pressure actuating system components, etc. To achieve the effect of simple on-site operation, convenient operation and control, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

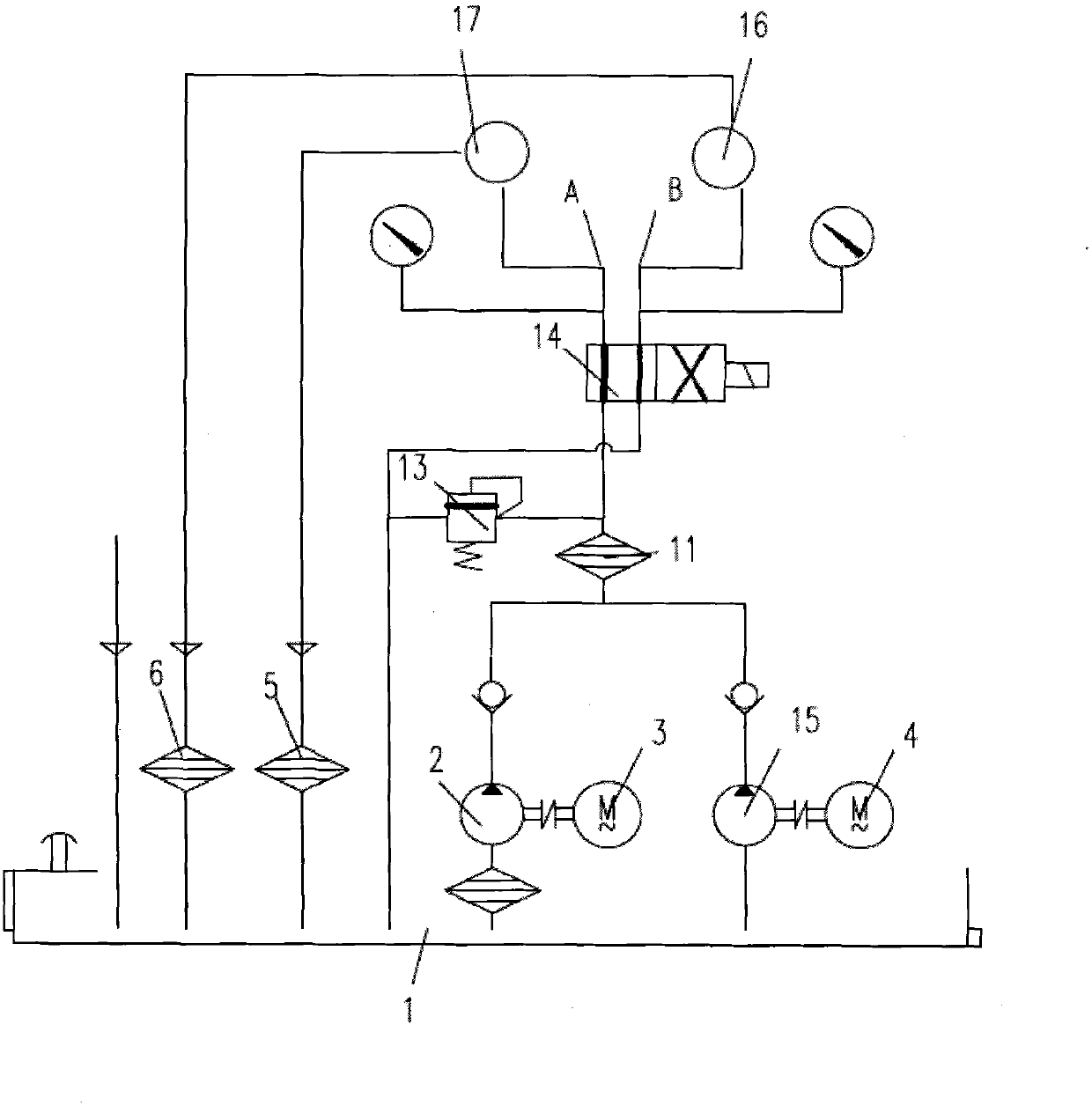

[0030] Specific embodiments of the present invention will be described below with reference to the drawings.

[0031] The hydraulic system of the rail welding car includes a hydraulic pump station for the rail welding car, which is used to provide a common pressure oil source for the outrigger hydraulic subsystem 16 and the crane hydraulic subsystem 17 of the rail welding car. For the sake of construction safety, the crane hydraulic subsystem 16 and the outrigger hydraulic subsystem 17 are not allowed to work at the same time, so setting up a public hydraulic pump station for them can not only improve safety and reduce costs, but also does not affect the actual use effect .

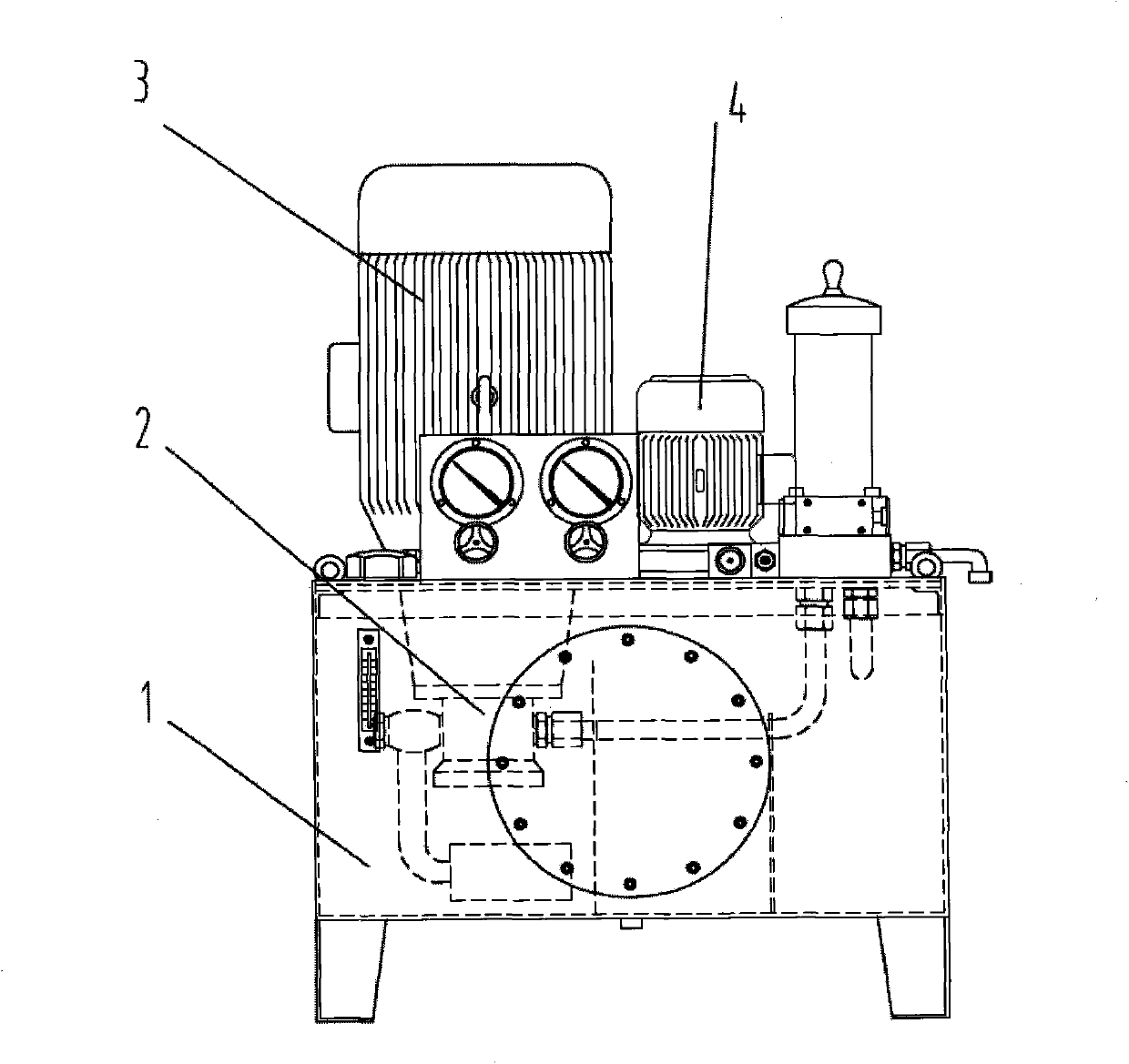

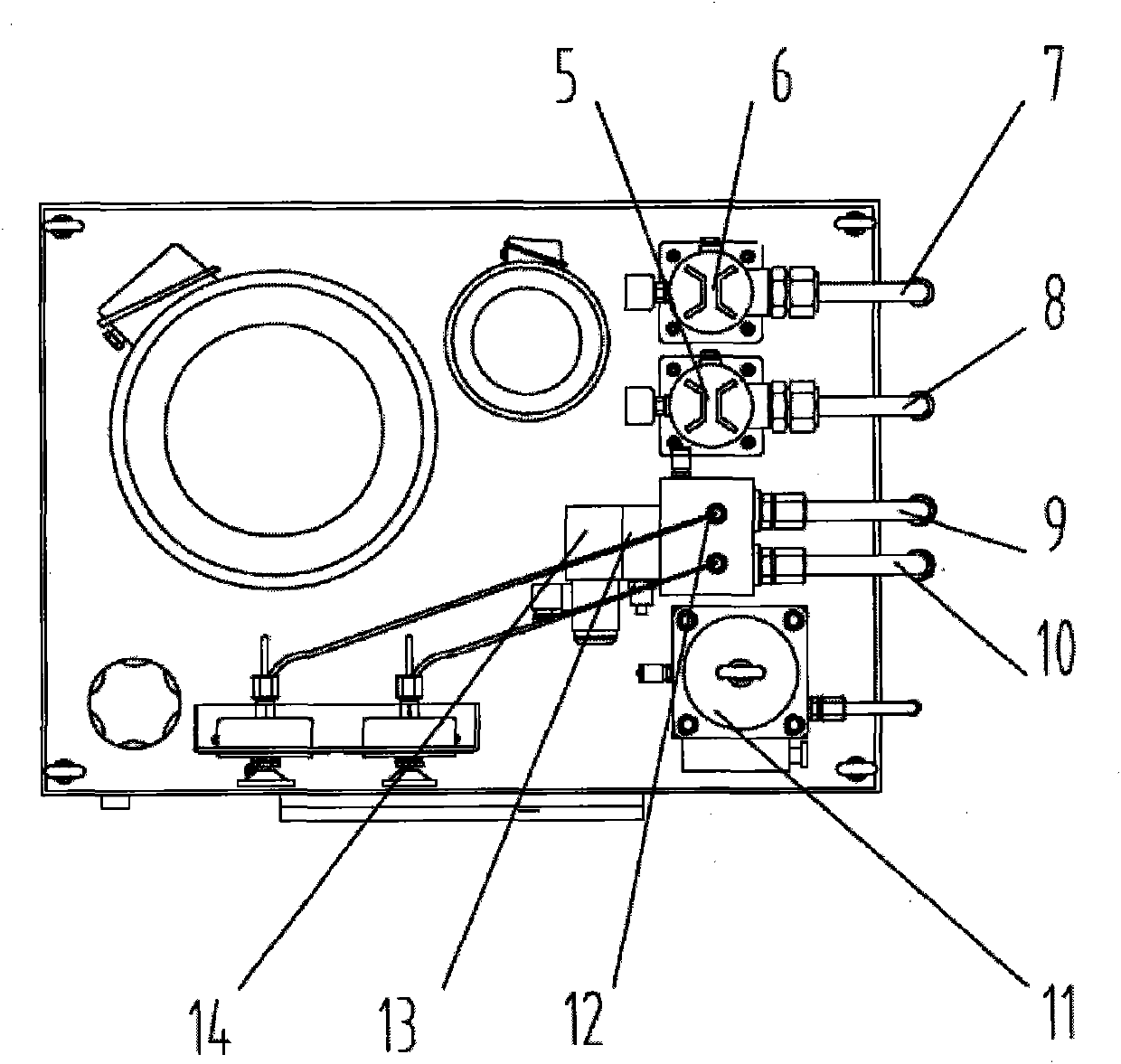

[0032] combine figure 1 , figure 2 with image 3 , the hydraulic pump station is a vertical structure, including a main body, the main body is provided with a fuel tank 1 and a main oil pump 2 connected to the fuel tank 1, and a main motor 3 is installed above the main body to provide power for the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com