Liquid ammonia safety protection control method

A control method, liquid ammonia technology, applied in the field of storage control and liquid ammonia production, can solve problems such as loss and safety hazards, liquid ammonia easily pollutes the environment, and ammonia gas gushes out, and achieves the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

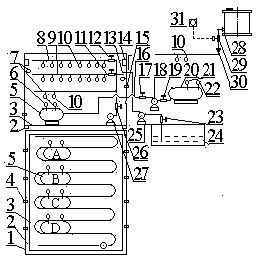

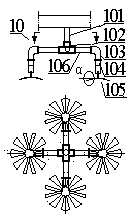

[0042] Refer to attached Figure 1-5 , Embodiment 1 of the present invention is a kind of liquid ammonia security control method, when DCS normal control, pre-set liquid ammonia gas concentration alarm high limit value E (120ppm), F (35LEL%), set the alarm height Limits G (150ppm), H (50LEL%), pre-set liquid ammonia storage tank 7 ℃ ammonia storage tank two A / B remote pressure gauge detection value high limit I (1.4Mpa), -35 ℃ ammonia storage The upper limit of the detection value of the two C / D remote pressure gauges for the tank is J (1.1Mpa), and the upper limit of the detection value of the two A / B remote pressure gauges for the liquid ammonia storage tank at 7°C is preset M( 1.6Mpa), -35°C ammonia storage tank two C / D remote pressure gauge detection value high limit N (1.3Mpa).

[0043] The liquid ammonia security control system is in the automatic state. When the liquid ammonia gas alarm device 7, 22 detects that the liquid ammonia concentration reaches the set alarm up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com