Heavy-caliber quartz capsule/stick drawing molding device

A quartz tube and large-diameter technology, which is applied in the field of ultra-large-diameter quartz tube/rod drawing and forming devices, can solve the problem that the vertical sides of the working tractor are unbalanced with each other, the outer diameter of the quartz tube/rod is different, and the product qualification rate is reduced. and other problems, to achieve the effect of overcoming the repeated accumulation of mechanical gaps, reducing the accumulation of mechanical gap errors, and reasonably configuring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

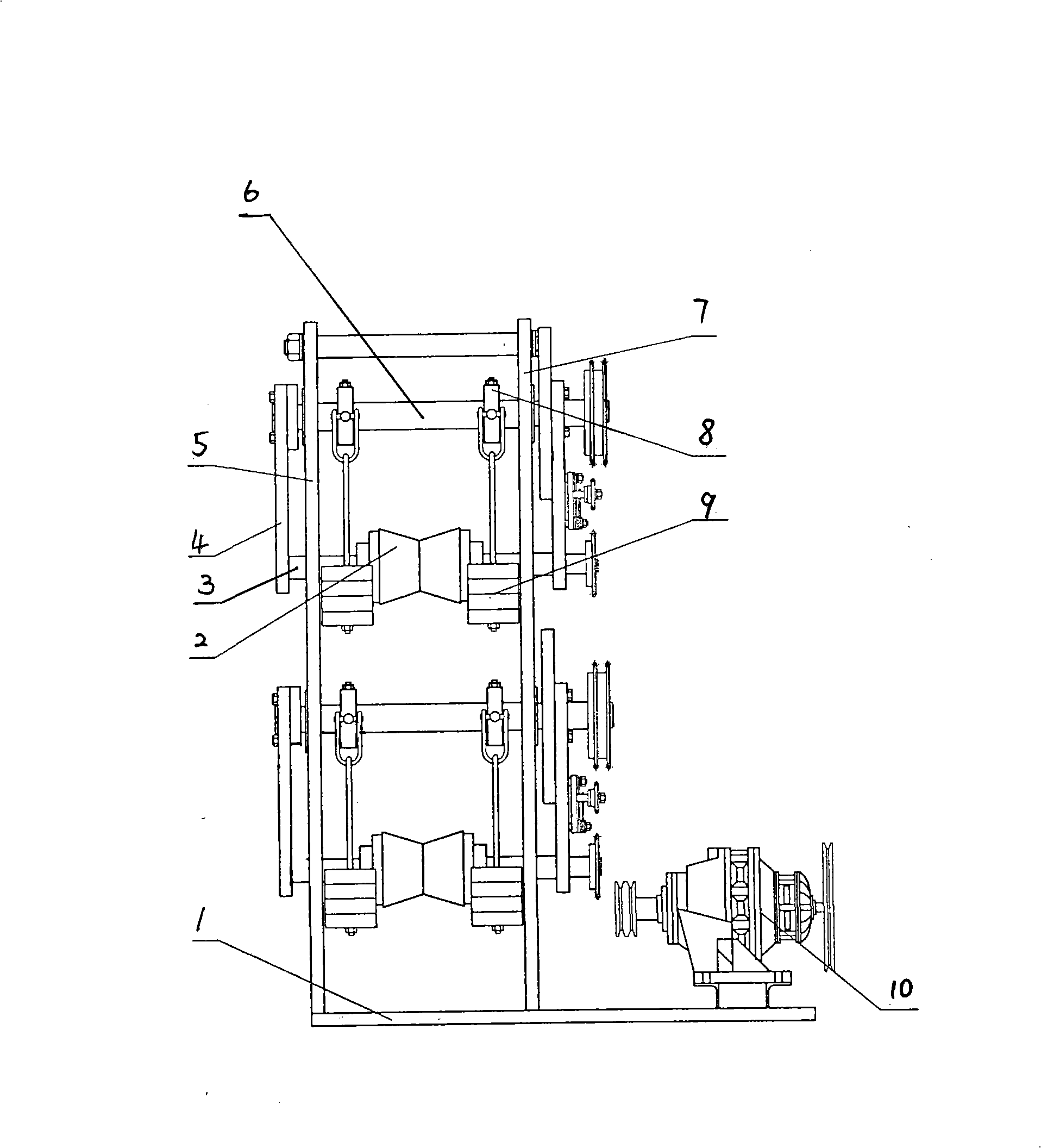

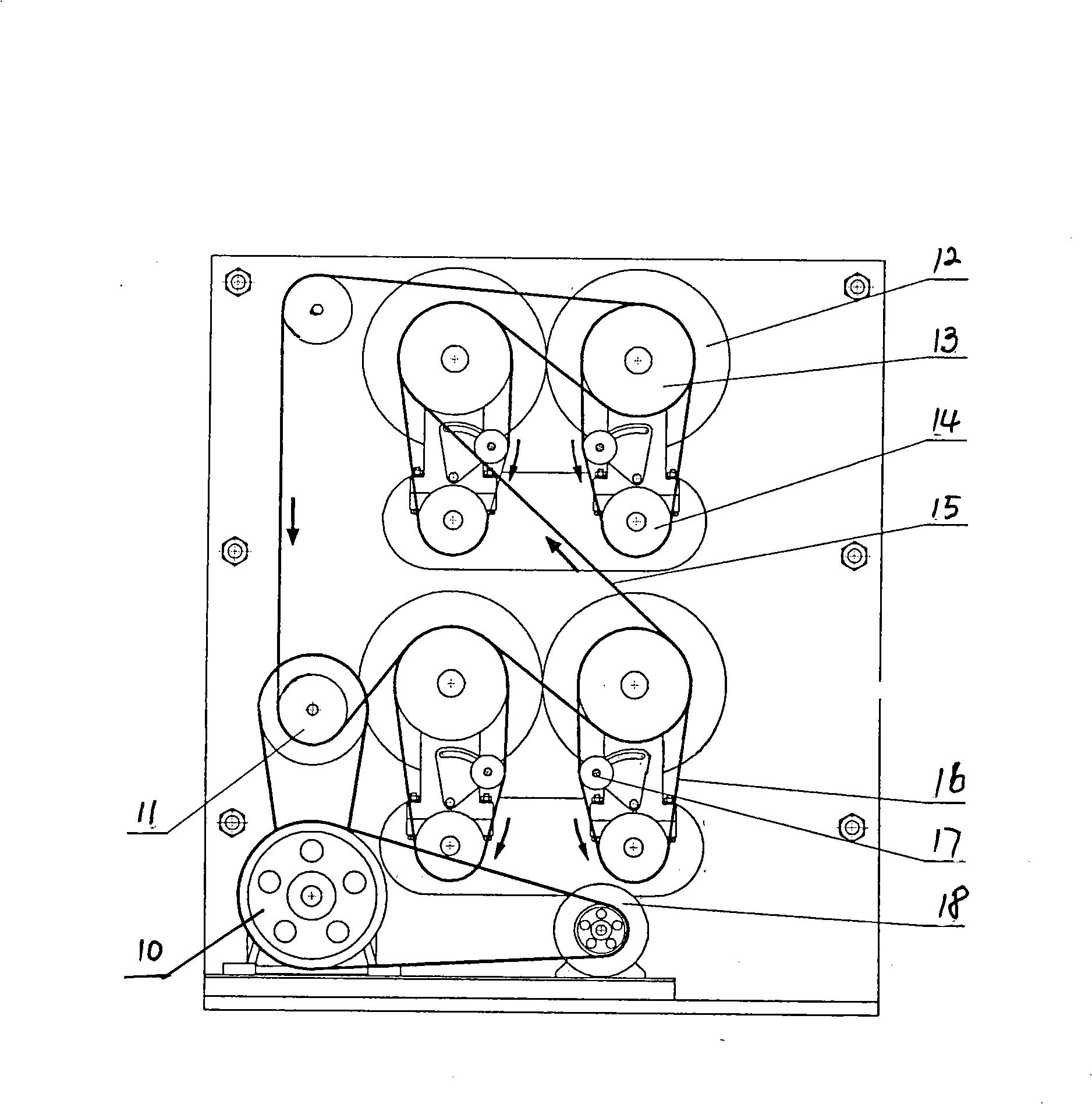

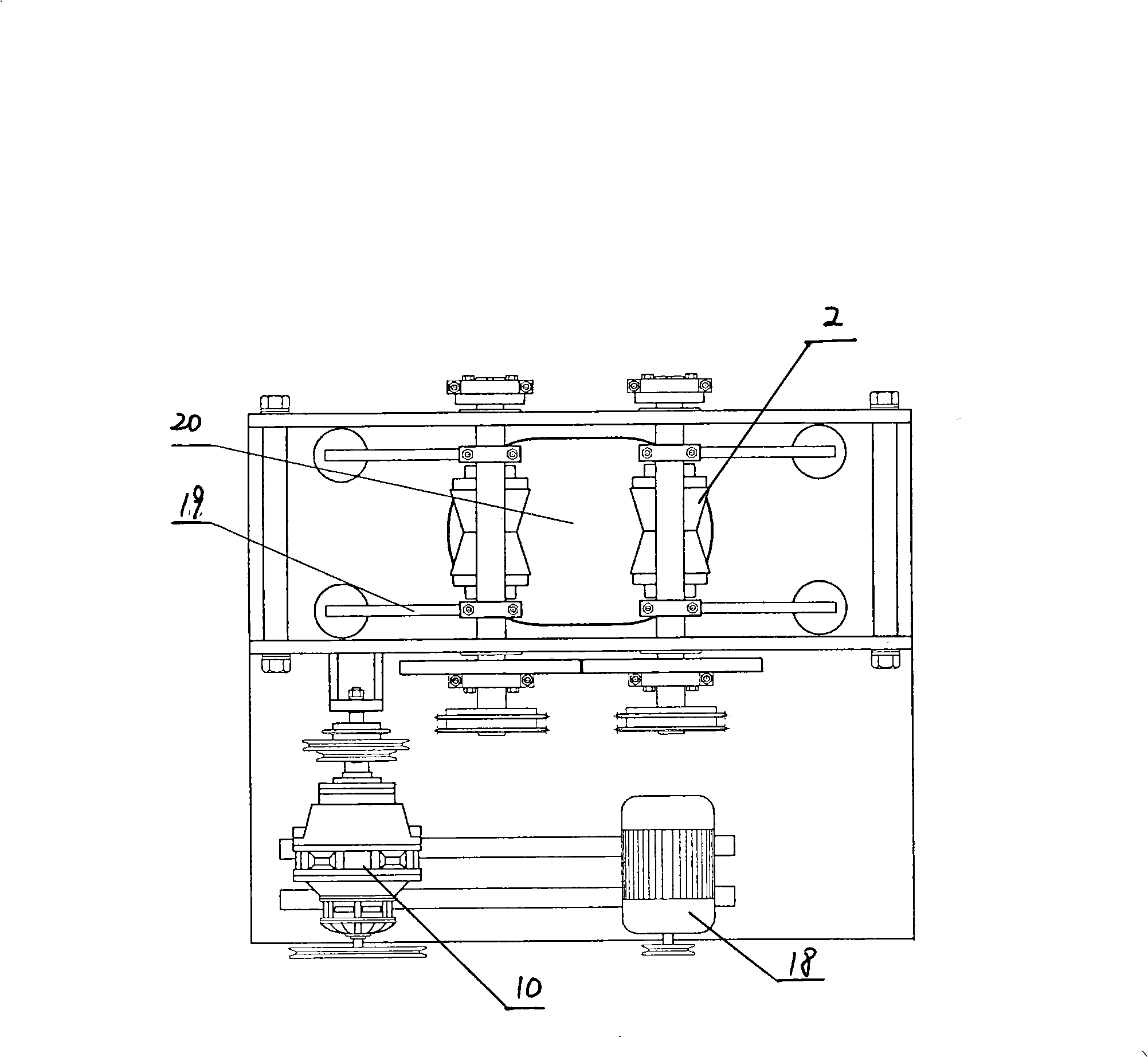

[0015] A large-diameter quartz tube / rod drawing forming device, its frame 1 includes two front and rear box plates 5, 7 and a bottom plate, and a tube outlet is opened on the bottom plate, which is convenient for the tube to be discharged between the front and rear box plates. The base plate is positioned at the front and rear panel bottoms, and is fixed with bolts to form a whole frame, and a cycloidal pinwheel reducer 10 and a motor 18 are installed on the base plate as a power source.

[0016] Between the front and rear boxboards on the frame 1, 1 to 3 sets of traction mechanisms are vertically arranged, and each set of traction mechanisms includes a pair of traction wheels 2 symmetrically arranged left and right, and a pipe outlet channel 20 is formed between the traction wheels 2, and the traction wheels 2. It is fixedly installed in the middle of the swing shaft 3. A transmission shaft 6 is arranged above the swing shaft 3. The two ends of the transmission shaft 6 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com