Preparation method of KTP crystal with anti-soil performance

An anti-gray trace and crystal technology is applied in the field of preparation of KTP crystals with anti-gray trace performance, which can solve the problems of reducing the nonlinear efficiency of the crystal, the decrease of the frequency doubling efficiency of the device, and the heating of the crystal, and achieves good anti-gray trace ability, times the The effect of high frequency conversion efficiency and good withstand voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

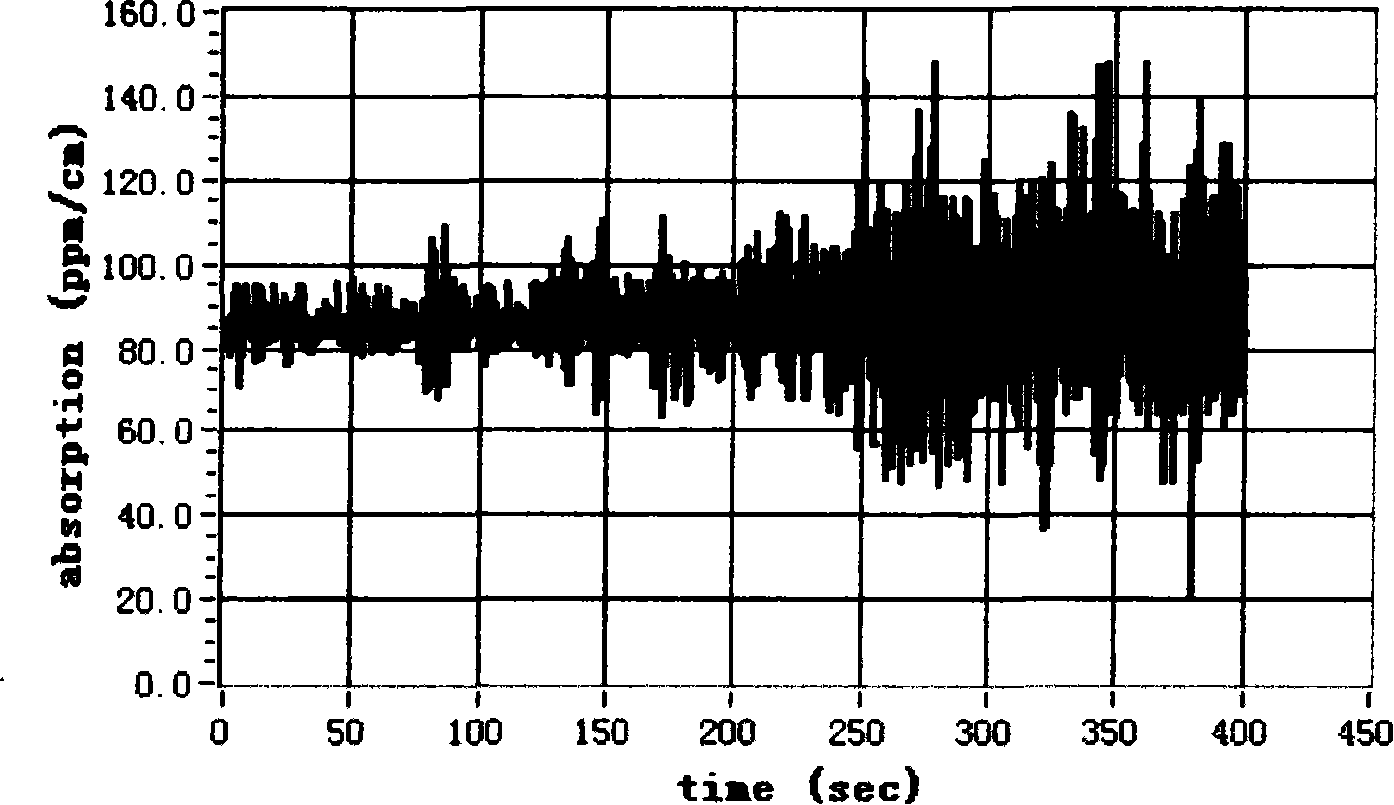

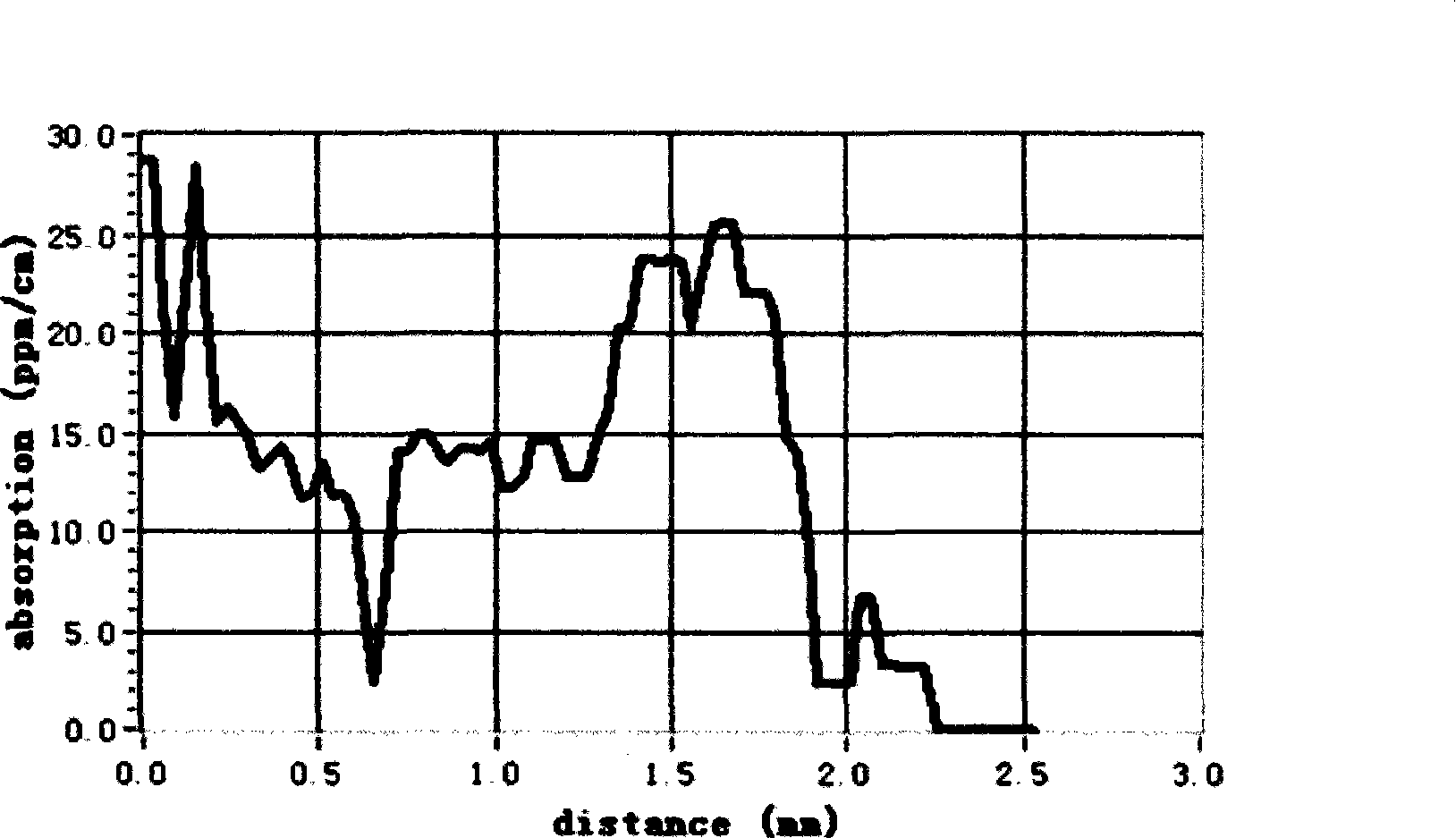

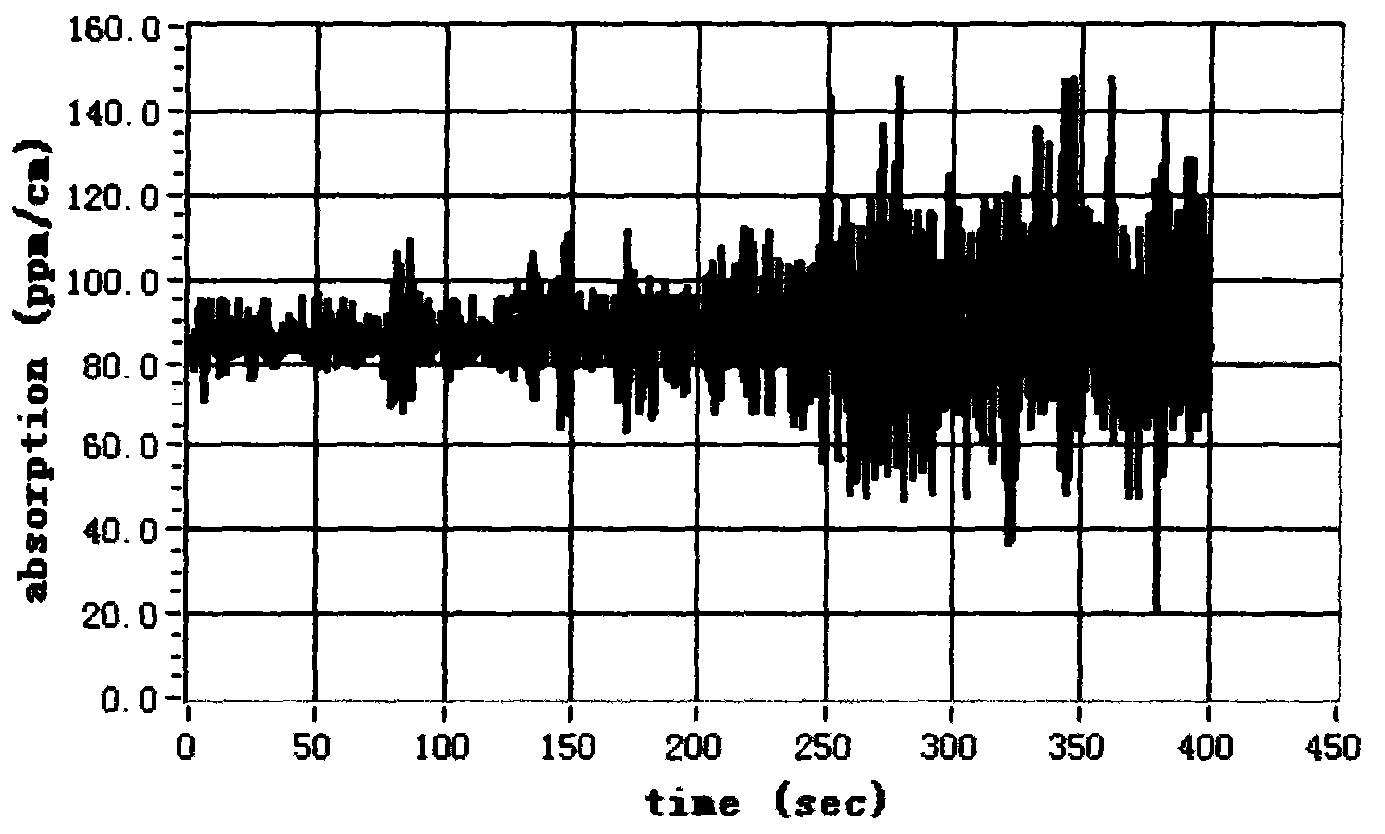

Image

Examples

Embodiment Construction

[0018] The chemical equation for the reaction to generate K4 flux and KTP:

[0019] K4 Flux: 2K 2 HPO 4 ---K 4 P 2 o 7 +H 2 o

[0020] KTP crystal: KH 2 PO 4 +TiO 2 ---KTiOPO 4 +H 2 o

[0021] Relative to K 6 P 4 o 13 Flux grown KTP, K 4 P 2 o 7 The temperature range in which the flux can grow stably is much narrower, and the growth is relatively difficult, and the amount of solute KTP precipitated in the stable growth temperature range is relatively small. In a crucible with a diameter of 150 mm and a height of 100 mm, KH 2 PO 4 and TiO 2 , the raw material K of synthetic K4 fluxing agent 2 HPO 4 Mix with each other so that the fullness of the melt is 75% to 85%, and adjust the temperature in the crucible to be 3°C / 10cm to 8°C / 10cm. When the temperature is 5°C / 10cm, it is most conducive to the growth of the crystal; Melt and react the raw materials at 1000°C, and stir at constant temperature for 24 hours to form a uniform and stable high-temperature sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com