On-line automatic testing method and system for beam vibration fatigue reliability of micro electro-mechanical systems

An automatic testing system, micro-electromechanical system technology, applied in vibration testing, testing of machine/structural components, using repeated force/pulsation force to test the strength of materials, etc., to achieve simple system, low cost, automatic loading and measurement steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An online automatic test system for vibration fatigue reliability of MEMS beams. The material of MEMS beams is polysilicon. The geometric dimensions of MEMS beams are: 300 μm in length, 30 μm in width, and 2 μm in thickness, and the distance between the beam unit and the substrate 2μm, first use AC voltage to load the vibration fatigue load on the MEMS beam to make it vibrate for a specific number of times, the AC voltage amplitude is 7V, the frequency is 20KHz, the AC voltage plus

[0033] The loading time was 100 minutes, then, remove the above-mentioned vibration fatigue load (that is, stop adding the AC signal, and then load the DC measurement voltage on the MEMS beam, and the DC measurement voltage starts to add from 40V until the beam pulls in, and the measured Reflect the pull-in voltage value of the MEMS beam fatigue characteristics, repeat the above steps to alternate loading and measurement until the AC voltage loading time of the MEMS beam reaches 1500 minutes...

Embodiment 2

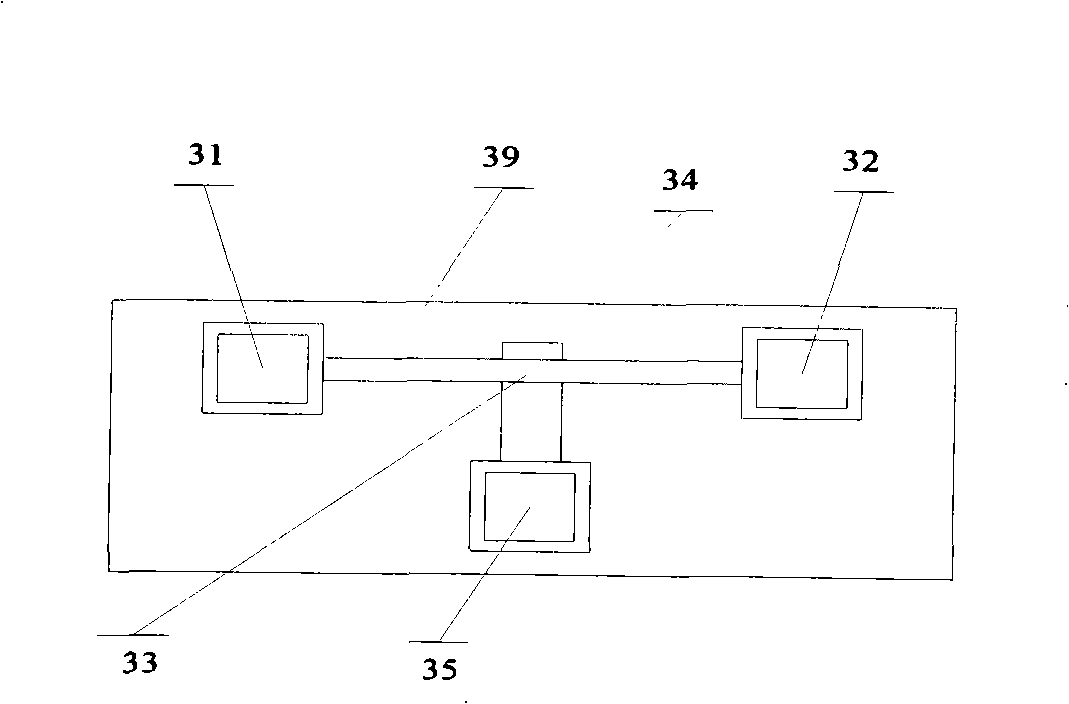

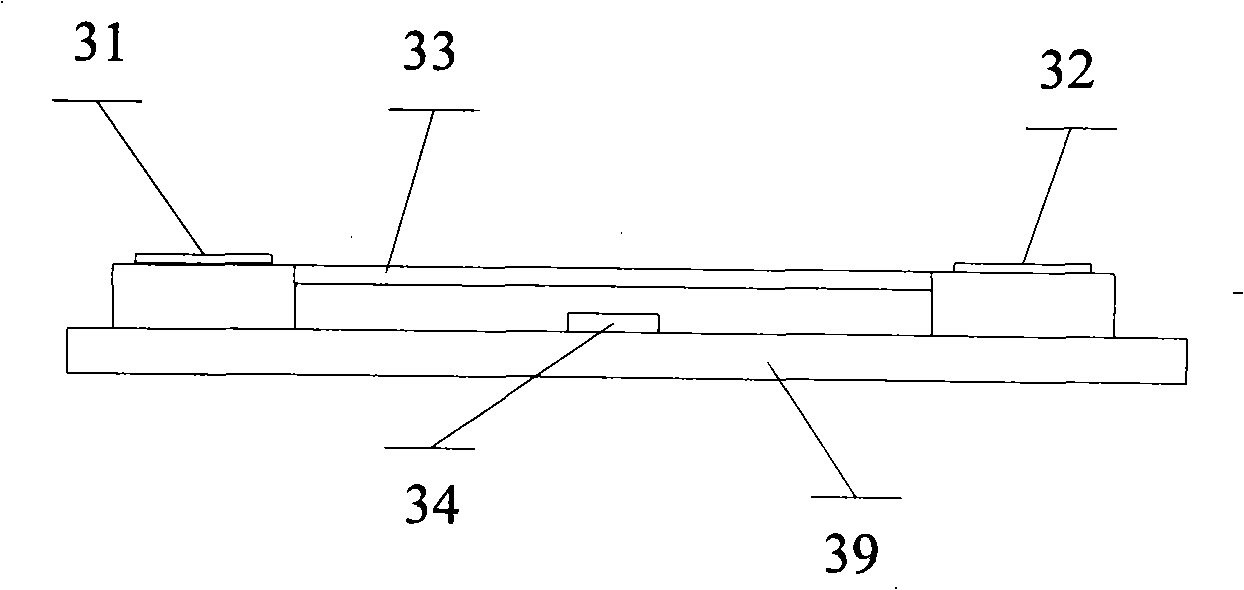

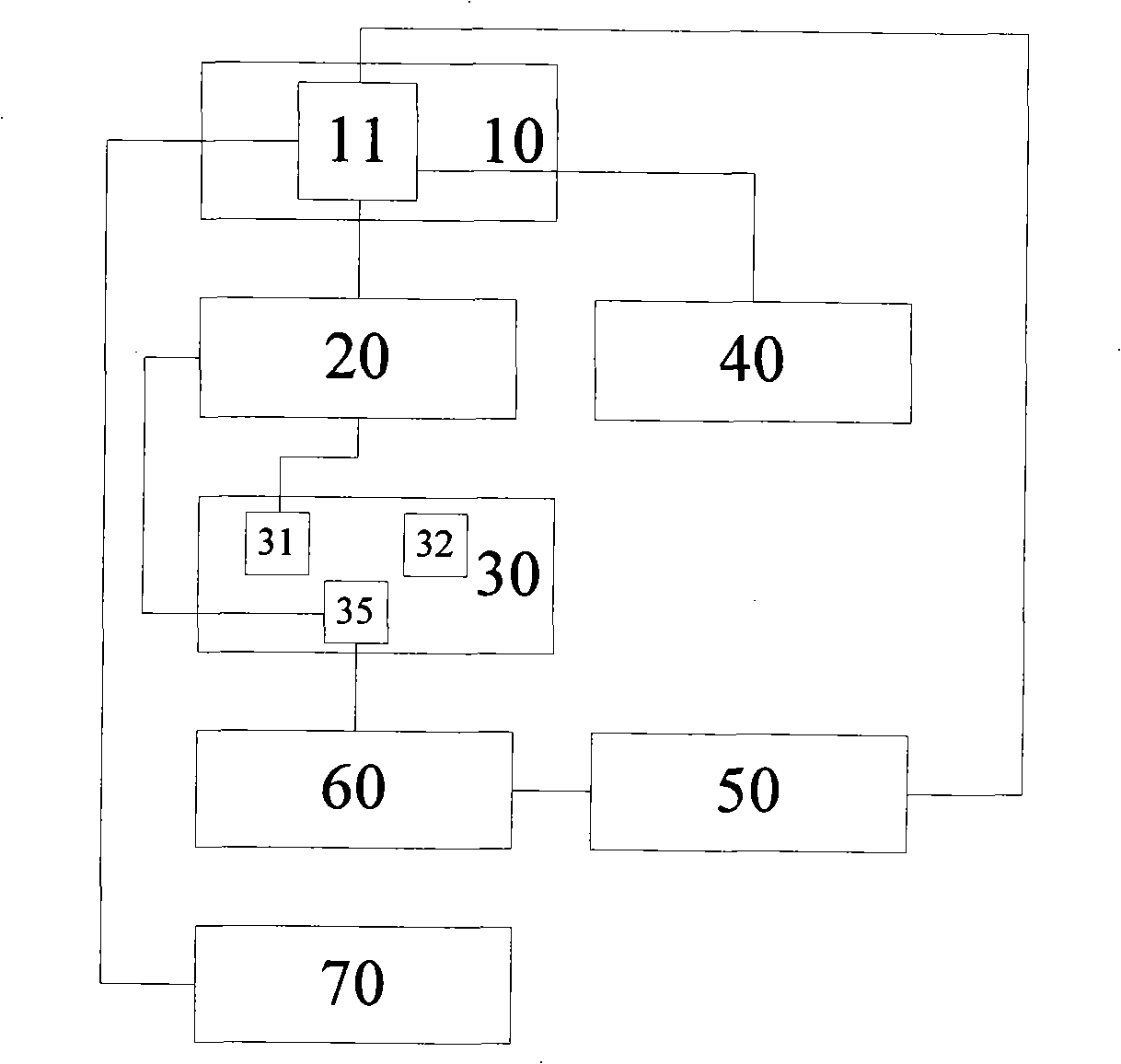

[0036] An online automatic test system for MEMS beam vibration fatigue reliability, consisting of a voltage generation module 10, an amplifier 20, a MEMS beam 30, a timer 40, a voltage detection module 50, a protection circuit 60 and a data output module 70, the voltage The generation module 10 generates AC voltage or DC voltage, and controls the conversion of AC and DC voltages through the program. The generated voltage is amplified by the amplifier 20 and then loaded onto the MEMS beam 30 to complete the measurement process of loading and pull-in voltage alternately. The voltage causes the MEMS beam 30 to vibrate and cause fatigue. The DC voltage is used as the pull-in voltage of the MEMS beam 30 to measure the voltage. The voltage detection module 50 detects the voltage drop of the protection circuit 60 by detecting the voltage change at both ends of the protection circuit 60. At the same time, record the pull-in voltage value and output the pull-in voltage value data of the...

Embodiment 3

[0043] An online micro-electro-mechanical system beam vibration fatigue characteristics automatic test system is composed of a voltage generation module 10, an amplifier 20, a micro-electro-mechanical system beam 30, a timer 40, a voltage detection module 50, a protection circuit 60 and a data output module 70. The module 10 generates AC voltage or DC voltage, and the timer 40 or the voltage detection module 50 sends a signal to the voltage generating module 10 to control the conversion of the AC and DC voltages through the program, and the generated voltage is amplified by the amplifier 20 and loaded into the MEMS On the beam 30, the measurement process of the loading or pull-in voltage is completed. The AC voltage makes the MEMS beam 30 vibrate and fatigue, and the DC voltage is used as the measurement voltage of the pull-in voltage of the MEMS beam 30. The voltage detection module 50 detects the protection circuit 60 When the voltage changes at both ends, the protection circ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com