Colorful laser printer and printing method

A laser printer, color technology, used in printing, optics, instruments, etc., can solve the problems of color registration errors and high requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

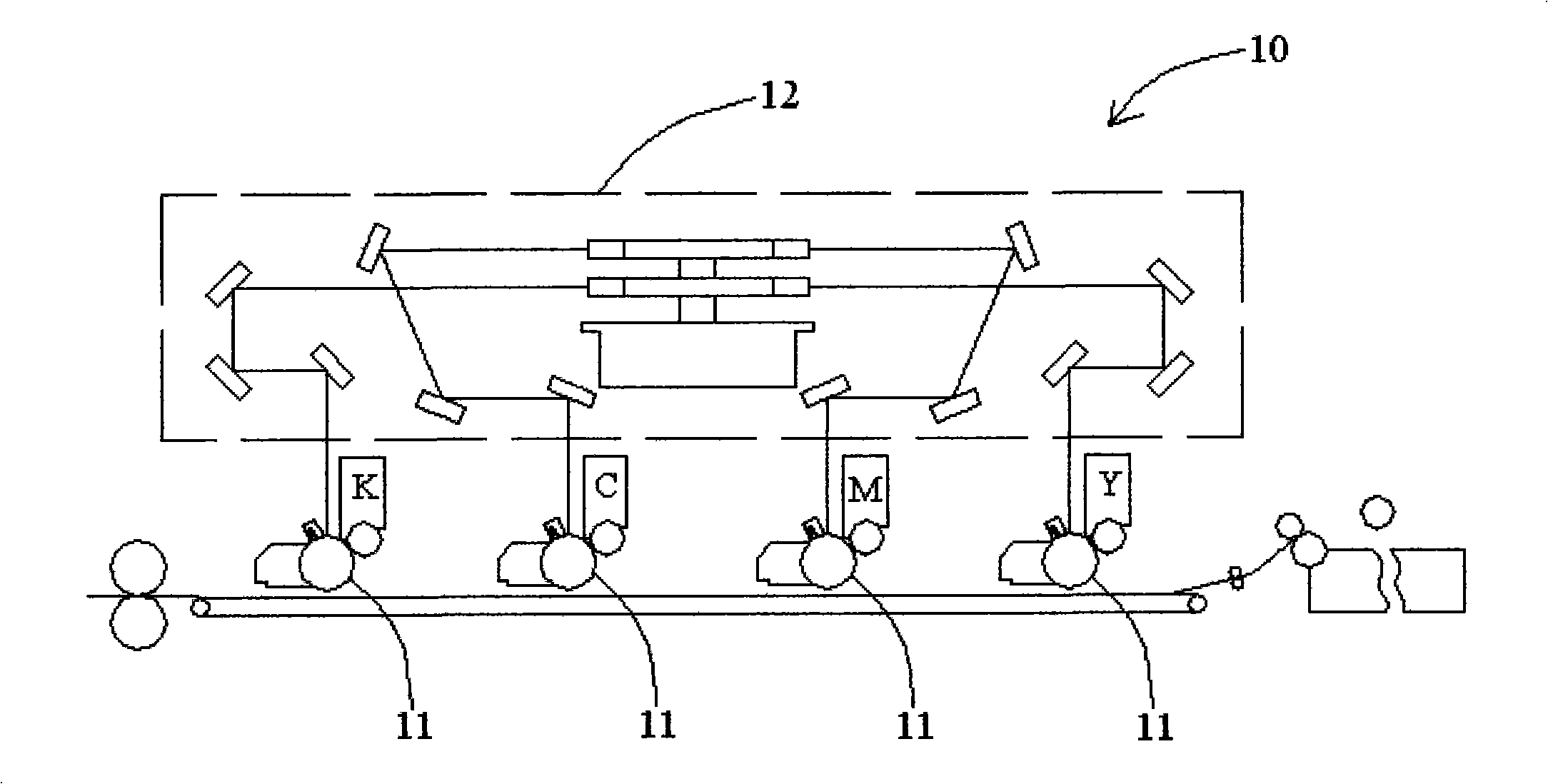

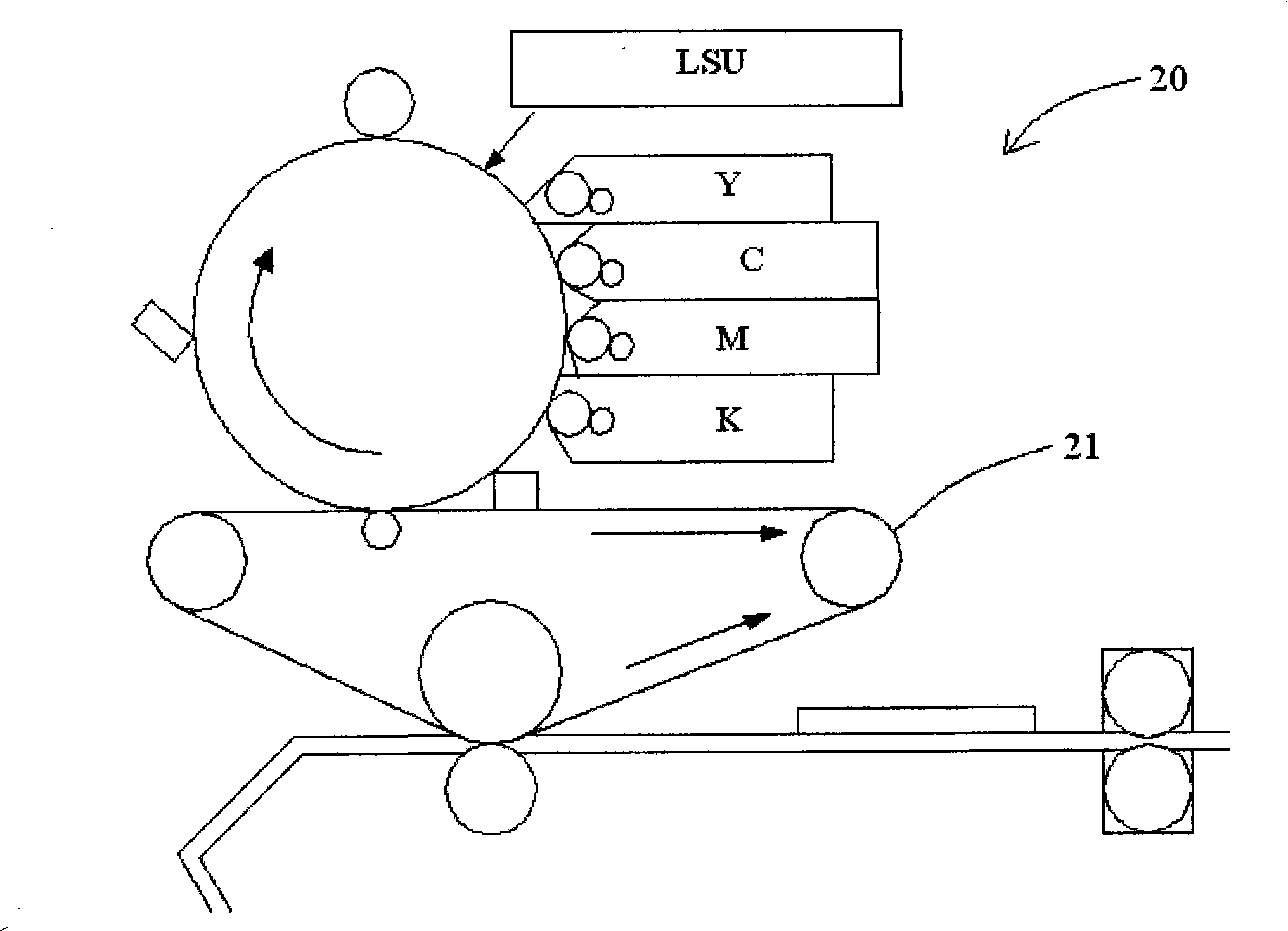

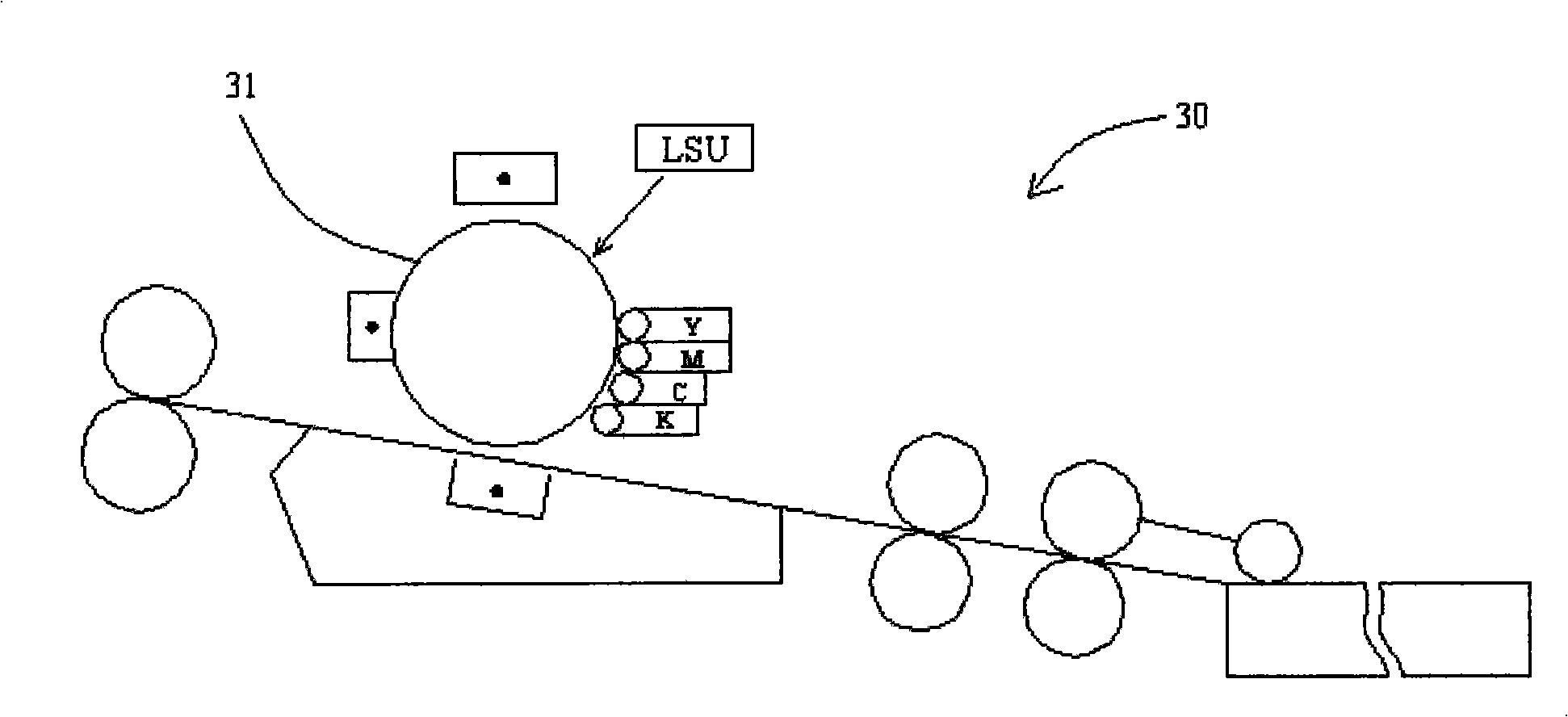

[0022] The basic structure and working principle of the color laser printer 100 provided by a preferred mode of the present invention will be described below with reference to figures.

[0023] see Figure 4 , a structural schematic diagram of the printer 100 of the preferred embodiment, the printer 100 includes a photosensitive drum 110, a charging unit 120, an exposure module 130, a developing module 140, a transfer roller 150, and a scraper 160 for removing residual toner particles.

[0024] Wherein the exposure module 130 includes a laser light source and a light source power control circuit, please refer to Figure 5 , the laser light source includes four laser diodes 131 combined in parallel, the ratio of the maximum output power of the four laser diodes 131 is P4:P3:P2:P1 is 192:48:12:4, wherein LD1 is controlled to provide four levels Power: 1 / 4P1, 2 / 4P1, 3 / 4P1 and P1, the LD2, LD3 and LD4 are controlled to provide three levels of power: 1 / 3P2, 2 / 3P2 and P2; 1 / 3P3, 2 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com