Electrifying device, process cartridge and image forming apparatus

A charging device and image technology are applied in the directions of corona discharge device, electric recording process applying charge pattern, equipment applying electric recording process of charge pattern, etc. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

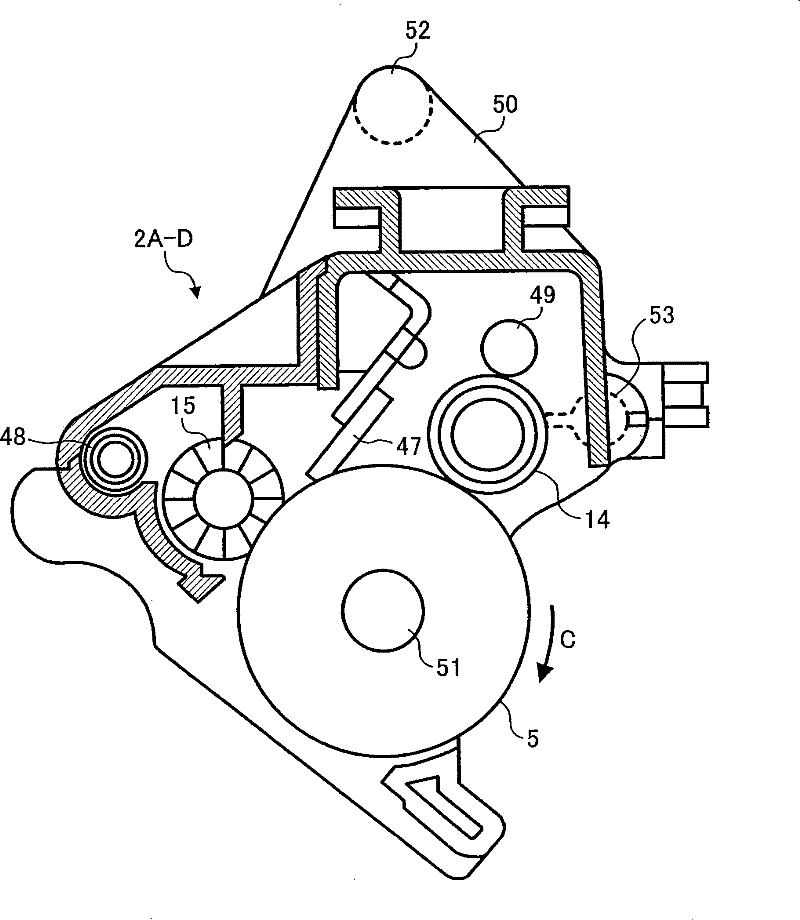

[0249] The charging rollers A-F formed according to the above-mentioned embodiments are exemplified below,

[0250] Charging roller A

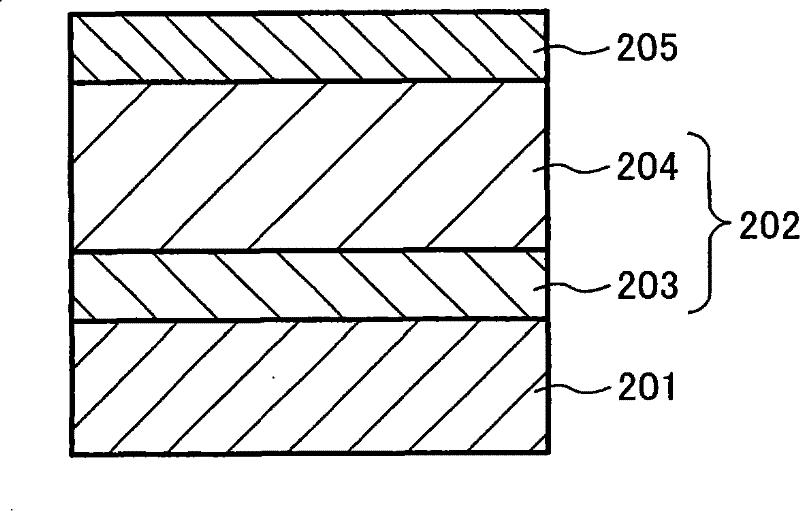

[0251] On a metal core with a diameter of 8 mm made of stainless steel, a charging layer was formed by injection molding, and the charging layer was composed of a resin composition (volume resistivity: 10 6 Ωcm), the above-mentioned resin composition is obtained by blending 60 parts by weight of an ion-conducting agent with 100 parts by weight of ABS resin, and the above-mentioned ion-conducting agent is composed of a polyolefin polymer compound having a quaternary ammonium base. A gap maintaining member was bonded to both ends of the charging layer. The gap maintaining member was composed of a polyethylene terephthalate film having a width of 8 mm and a thickness of 45 μm and an adhesive layer of 15 μm. The outer diameter of the charging layer is 11mm, making the above-mentioned charging roller (with Figure 6 constitute the same). The h...

no. 6 example

[0359] According to the sixth embodiment of the present invention, the charging roller 14 is fabricated as follows:

[0360] The charging member 14b is formed by injection molding on a metal core with a diameter of 8 mm made of stainless steel, and the charging member is made of a resin composition (volume resistivity of 10 6 Ωcm), the above-mentioned resin composition is obtained by blending 60 parts by weight of an ion-conducting agent with 100 parts by weight of ABS resin, and the above-mentioned ion-conducting agent is composed of a polyolefin polymer compound having a quaternary ammonium base.

[0361] A polyethylene gap holding member 14c was bonded to both ends of the charging member 14b, and then ground so that the difference in outer diameter between the charging member 14b and the gap holding member 14c was 50 μm, and a charging roller (with a diameter of 12 mm) was fabricated. Figure 12 constitute the same).

no. 7 example

[0362] According to the seventh embodiment of the present invention, the charging roller 14 is fabricated as follows:

[0363] The charging roller 14 was produced using the same material as that of the charging roller in the fourth embodiment described above, however, the conditions at the time of grinding were changed so that the roller wobbled greatly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com