Method and apparatus for flow control in a package dyeing machine

A cheese and equipment technology, which is applied in the direction of using electric device flow control, liquid/gas/steam yarn/filament treatment, liquid/gas/steam treatment of a certain length of textile materials, etc., can solve the problems of long time, energy waste, Issues such as adaptability and repeatability cannot be guaranteed to achieve the effect of improving fabric quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

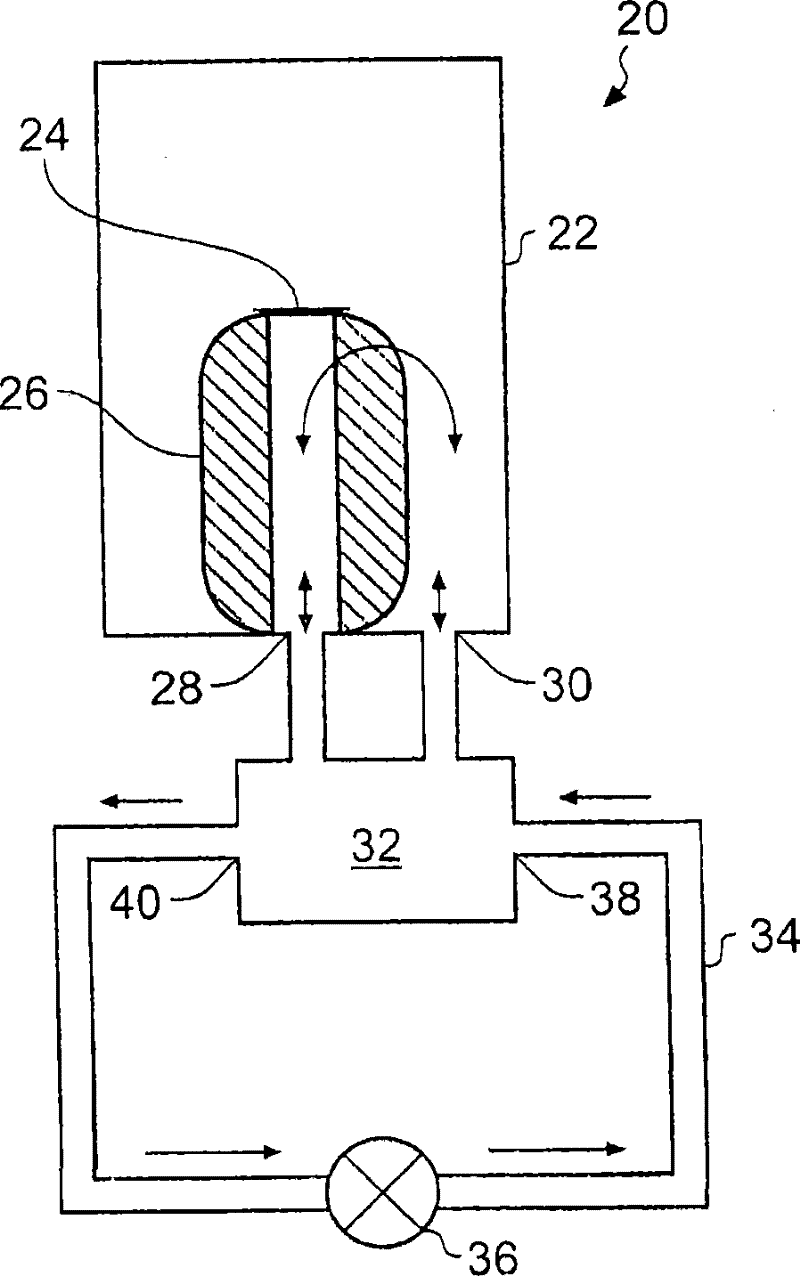

[0023] Figure 1 shows a simplified schematic diagram of a conventional cheese processing machine with a fluid circulation system. The dyeing machine 20 includes cylinders 22 for holding a plurality of cheeses during fluid handling processes such as dyeing. For simplicity of illustration, only one package 26 is shown. The cheese 26 is supported on an upstanding hollow yarn bamboo 24 extending upwardly from the base of the cylinder body 22 . The base of the cylinder block 22 also contains two fluid inlet / outlet ports. A port 28 is connected to the hollow interior of the gauze 24 . Another port 30 opens in the base of the cylinder 22 away from the gauze so as to communicate with the main volume of the cylinder.

[0024] A fluid circulation system is connected to the ports 28 , 30 and operates to circulate a treatment fluid through the cheese 26 . The system includes a pipe network 34 and a pump 36 located in the pipe network, the pump being operable to drive fluid around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com