Resistance spot welding quality control device and method based on electrode displacement

An electrode and displacement technology, used in resistance welding equipment, welding power sources, manufacturing tools, etc., can solve the problems of accuracy impact, difficulty in extracting solder joint quality information, difficult hidden Markov model, etc., to achieve strong anti-electromagnetic interference ability, The effect of solving the problem of welding quality fluctuation and meeting real-time requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

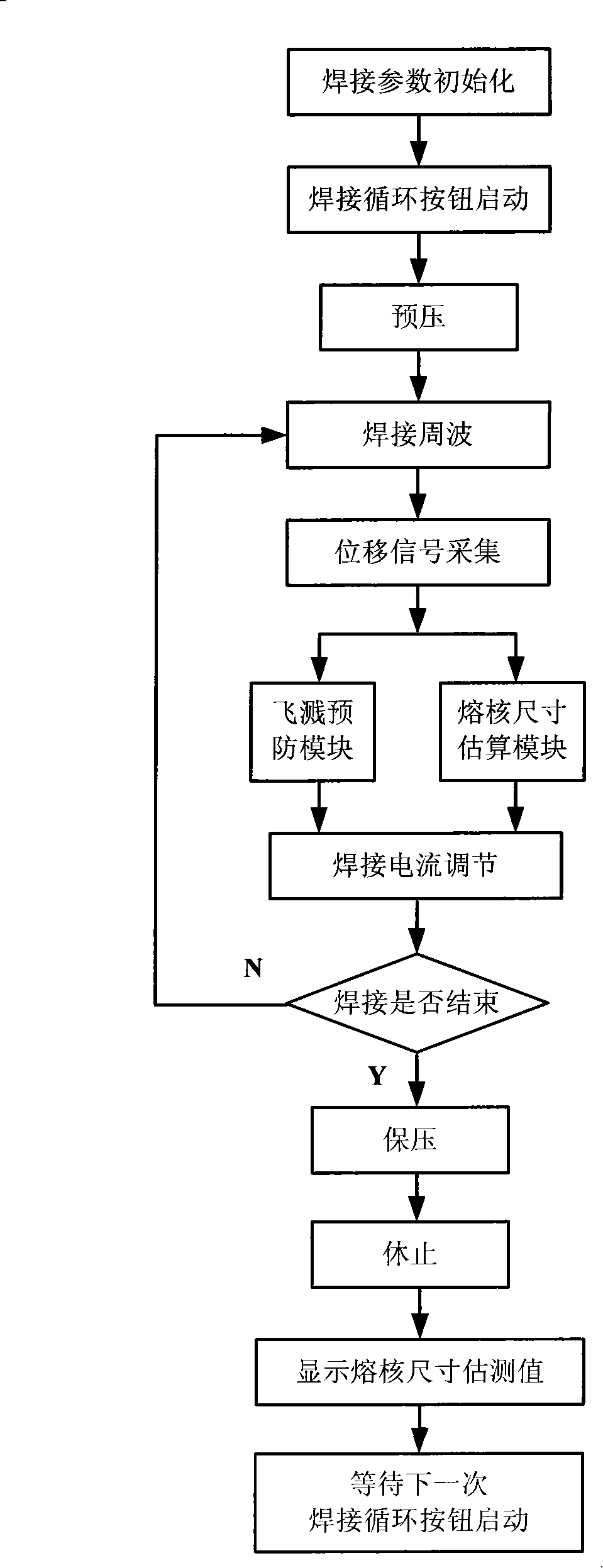

[0044] This embodiment takes the welding of 1 mm thick low carbon steel as an example, uses the collected electrode displacement signal as the observation value, uses the hidden Markov model to model, and estimates the size of the nugget diameter in real time. Hidden Markov model is a probability model with "double stochastic process", which has a good ability to deal with the random influencing factors in the welding process, and can better adapt to the highly nonlinear and multivariable coupling effects in actual welding and a large number of random uncertain factors.

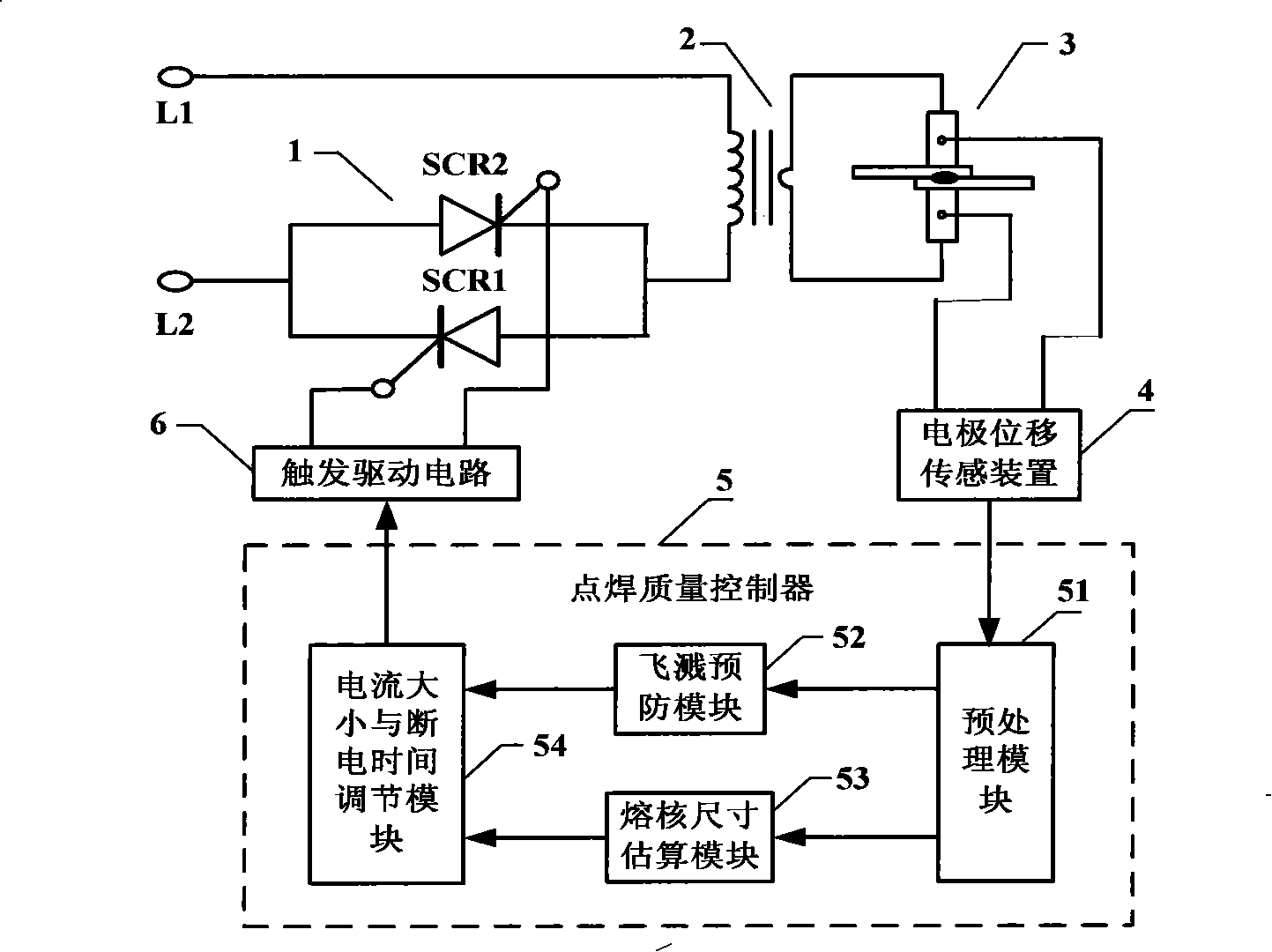

[0045] Such as figure 1 As shown, the resistance spot welding quality control device described in this embodiment includes: an anti-parallel thyristor 1, a welding transformer 2, an electrode 3 for clamping a workpiece, a displacement sensing device 4, a spot welding quality controller 5, and a trigger drive circuit 6.

[0046] The primary side of the anti-parallel thyristor 1 and a welding transformer 2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com