Oblique sphere type all-directional mobile wheel and uses thereof

A technology for all-round movement and moving wheels, which is applied in the direction of casters, wheels, transportation and packaging, etc., can solve the problems of poor flexibility and stability, low carrying capacity, poor obstacle-crossing ability, etc. Strong, Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

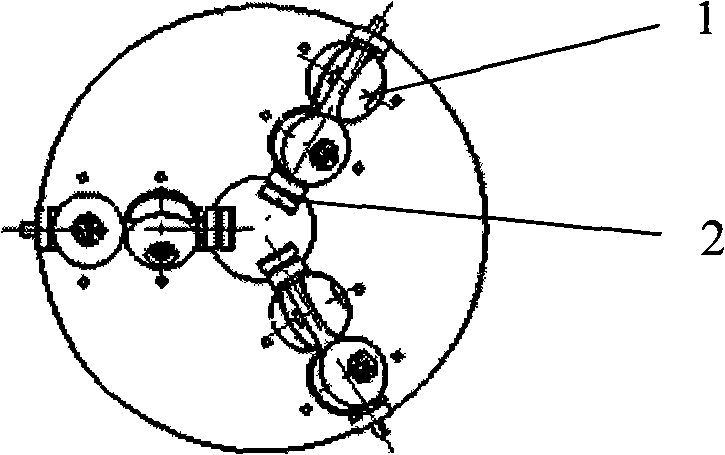

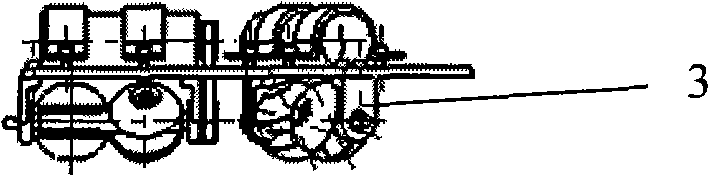

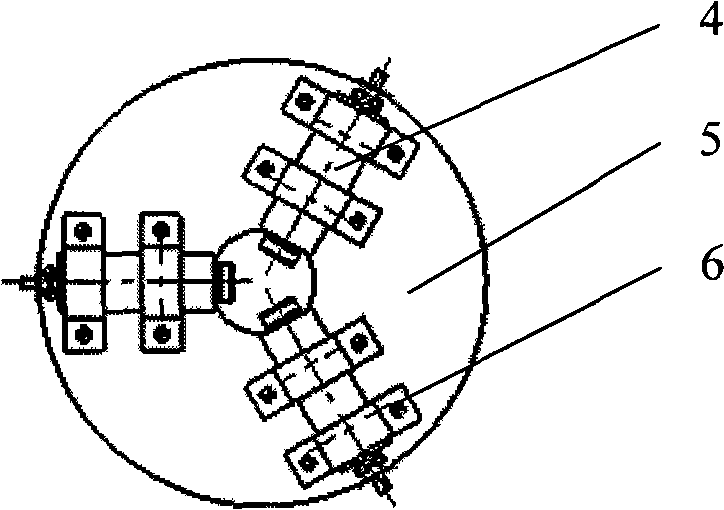

[0018] See Figure 1-Figure 7 , Oblique ball type omnidirectional moving wheel, which is composed of ball wheel a8 and ball wheel b9; the ball wheel a8 and ball wheel b9 are respectively fixed on the driving shaft 7 through the driven shaft a10 and the driven shaft b11, and the two driven shafts are in The vertical plane of the driving shaft 7 has an oblique angle of 45°, forming two oblique spherical split structures.

[0019] The ball wheel a8 and the ball wheel b9 are both composed of two spheres with a spherical cap and a part of the sphere removed, which are respectively connected to form a sphere part through a driven shaft a10 and a driven shaft b11, and are fixed on the driving shaft 7; two ball wheels The sphere part of the sphere together constitutes the entire sphere wheel structure, forming a complete circular projection on the vertical projection of the driving shaft 7.

[0020] The oblique ball type omnidirectional moving wheel 1 is used as a universal moving wheel of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com