Method for acid hydrolysis of acid soluble titanium slag

A technology of acid-soluble titanium slag and acidolysis, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of affecting production capacity, incomplete acidolysis of titanium slag, aging time and too long leaching, etc. Acid hydrolysis rate, wide application prospect, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

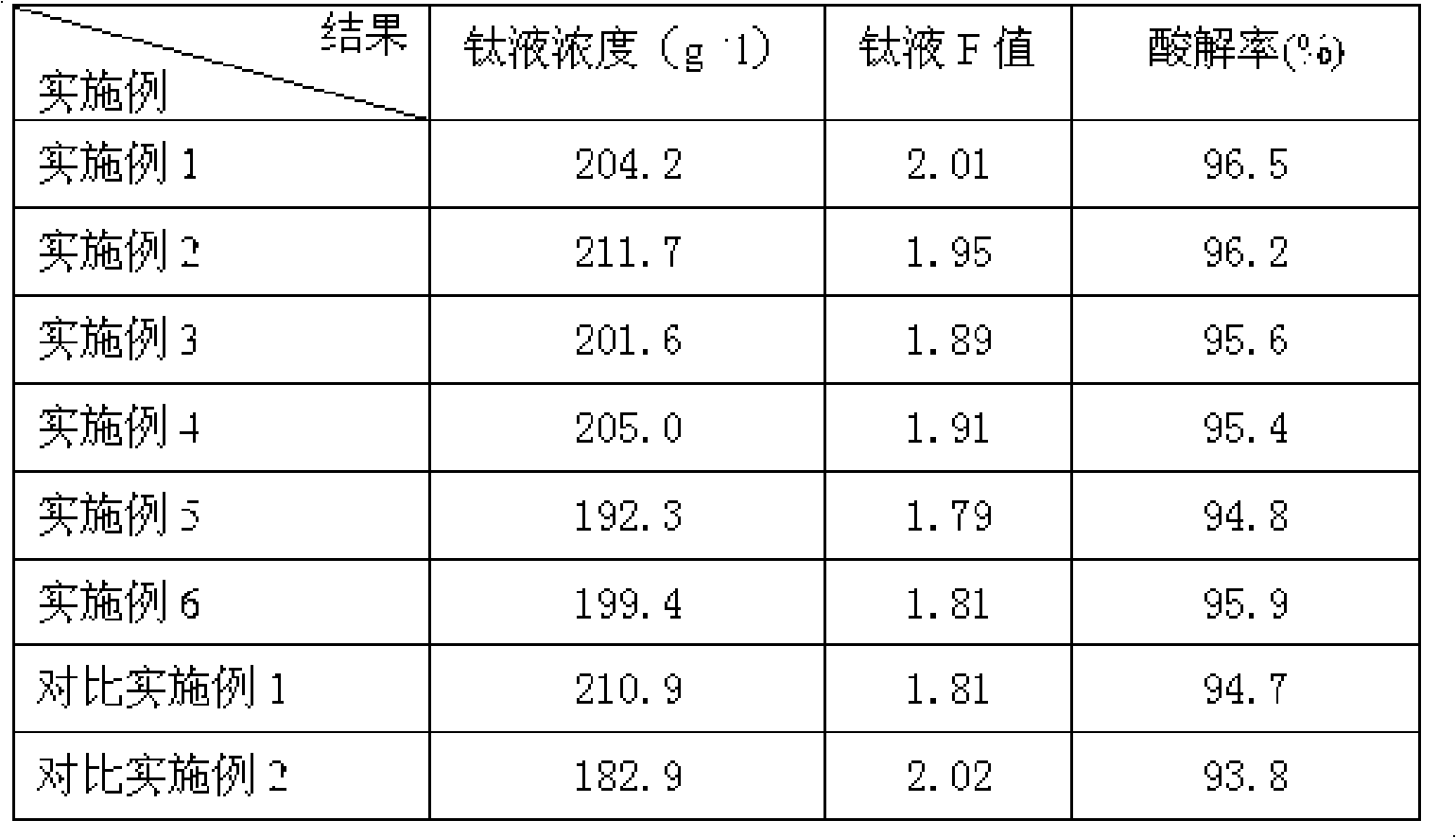

Examples

Embodiment 1

[0025] Prepare 6t of materials in the titanium slag preparation bin, with a volume of 30m 3 Injection quality is the sulfuric acid of 98% that the concentration that is 1.80 times of acid-soluble titanium slag quality (compared with 100% sulfuric acid) is the sulfuric acid of 98% in the acidolysis pot, opens compressed air, and air pressure is set to 2kg. Then put the titanium slag in the titanium slag preparation bin into the acid hydrolysis pot at one time, and stir it with air pressure for 40 minutes. Turn on the steam, the steam pressure is controlled to be 0.35Mpa, the steam feeding time is 35min, and when the temperature of the mixed material is 190°C, stop feeding the steam. After the main reaction of acidolysis occurs, the mixed material is matured and leached to obtain titanium liquid. There is no solid phase at the bottom of the acid hydrolysis pot.

Embodiment 2

[0027] Prepare 6t of materials in the titanium slag preparation bin, with a volume of 30m 3 Injection quality is the sulfuric acid of 98% that the concentration of acid-soluble titanium slag quality 1.75 times (compared with 100% sulfuric acid) is 98% sulfuric acid in the acidolysis pot, opens compressed air, and air pressure is set to 2kg. Then put the titanium slag in the titanium slag preparation bin into the acid hydrolysis pot at one time, and stir it with air pressure for 30 minutes. Turn on the steam, the steam pressure is controlled to be 0.40Mpa, the steam feeding time is 28min, and when the temperature of the mixed material is 185°C, stop feeding the steam. After the main reaction of acidolysis occurs, the mixed material is matured and leached to obtain titanium liquid.

Embodiment 3

[0029] Prepare 6t of materials in the titanium slag preparation bin, with a volume of 30m 3 Injection quality is the sulfuric acid of 97.2% that the concentration of 1.70 times (compared with 100% sulfuric acid) of acid-soluble titanium slag quality is the sulfuric acid of 97.2% in the acidolysis pot, opens compressed air, and air pressure is set to 2kg. Then put the titanium slag in the titanium slag preparation bin into the acid hydrolysis pot at one time, and stir it with air pressure for 45 minutes. Turn on the steam, the steam pressure is controlled to be 0.30Mpa, the steam feeding time is 30min, and when the temperature of the mixed material is 185°C, stop feeding the steam. After the main reaction of acidolysis occurs, the mixed material is matured and leached to obtain titanium liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com