Rotary type fluid-distributing valve

A fluid distribution valve, rotary technology, applied in fluid pressure actuating devices, valve details, multi-port valves, etc., can solve the problems that the performance indicators cannot meet the actual application requirements, high complexity, poor reliability, etc., and achieve strong practicality. Portability and portability, improved reliability, high reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

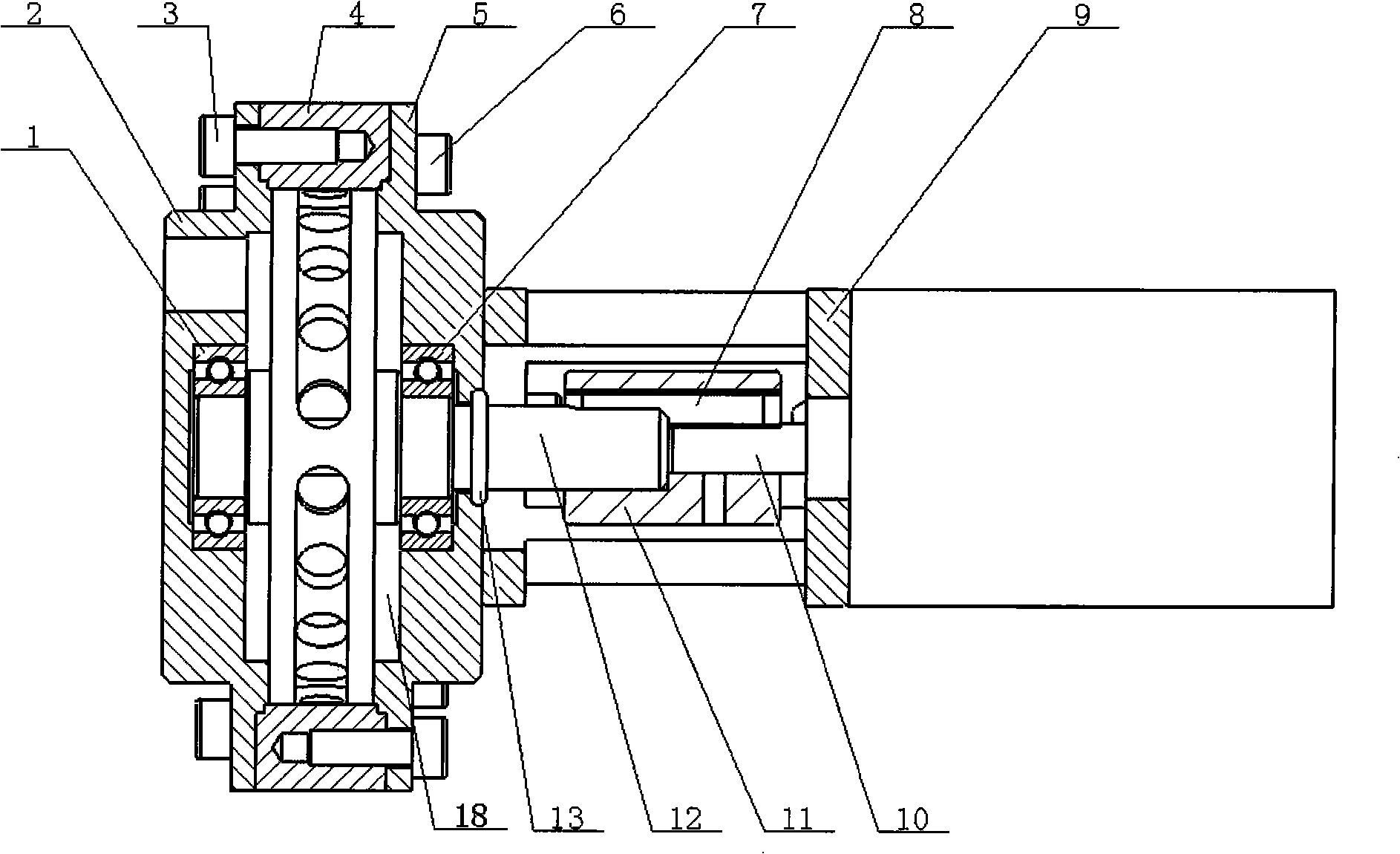

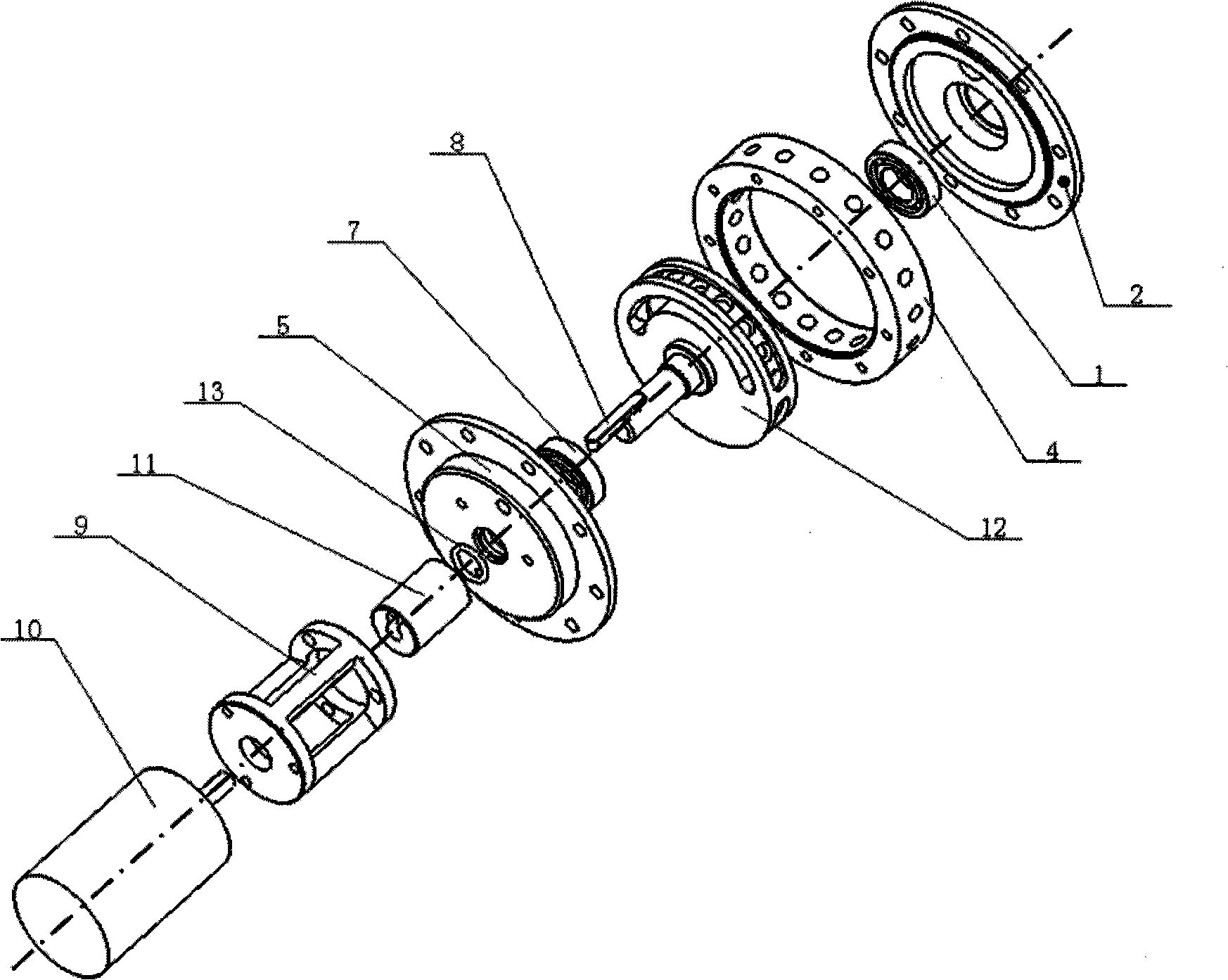

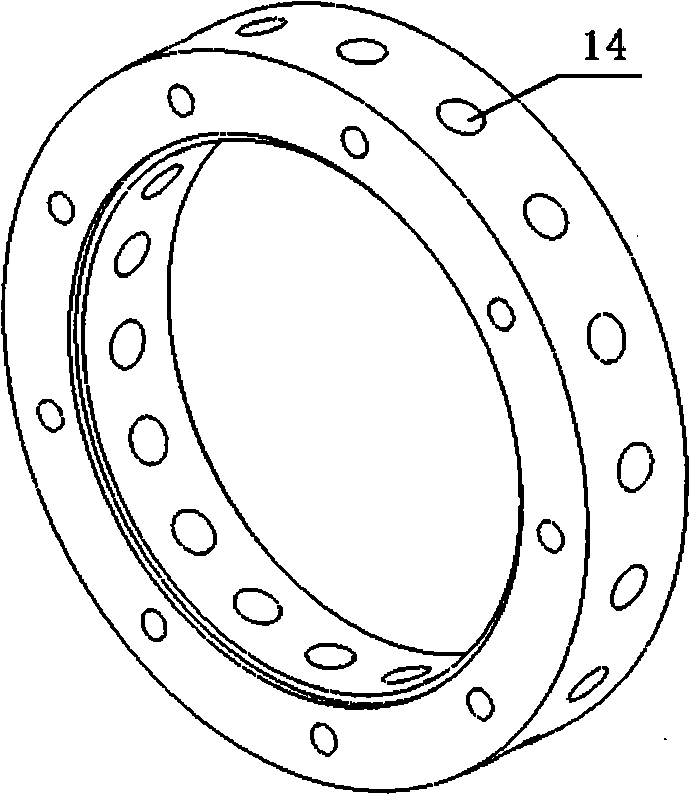

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the rotary fluid distribution valve of the present invention includes a valve body 4, a rotary valve core 12, a drive motor 10, a closed end cover 2 and an open end cover 5, and the closed end cover 2 and the open end cover 5 are respectively connected to The two ends of the valve body 4 form a closed cavity 18, one end of the rotary valve core 12 installed in the closed cavity 18 is connected with the drive motor 10, the closed end cover 2 in the closed cavity 18 is connected with the rotary valve core 12, the valve A high-pressure oil chamber is formed between the body 4, a low-pressure oil chamber is formed between the open end cover 5 and the rotary valve core 12, and the valve body 4, and there is no communication between the high-pressure oil chamber and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap