Hydraulic reverse valve oil head test control device

A hydraulic reversing valve and control device technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of increased labor intensity of test personnel, low test efficiency, complicated and cumbersome test process, etc., and reduce labor costs. Intensity, full automation, and the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

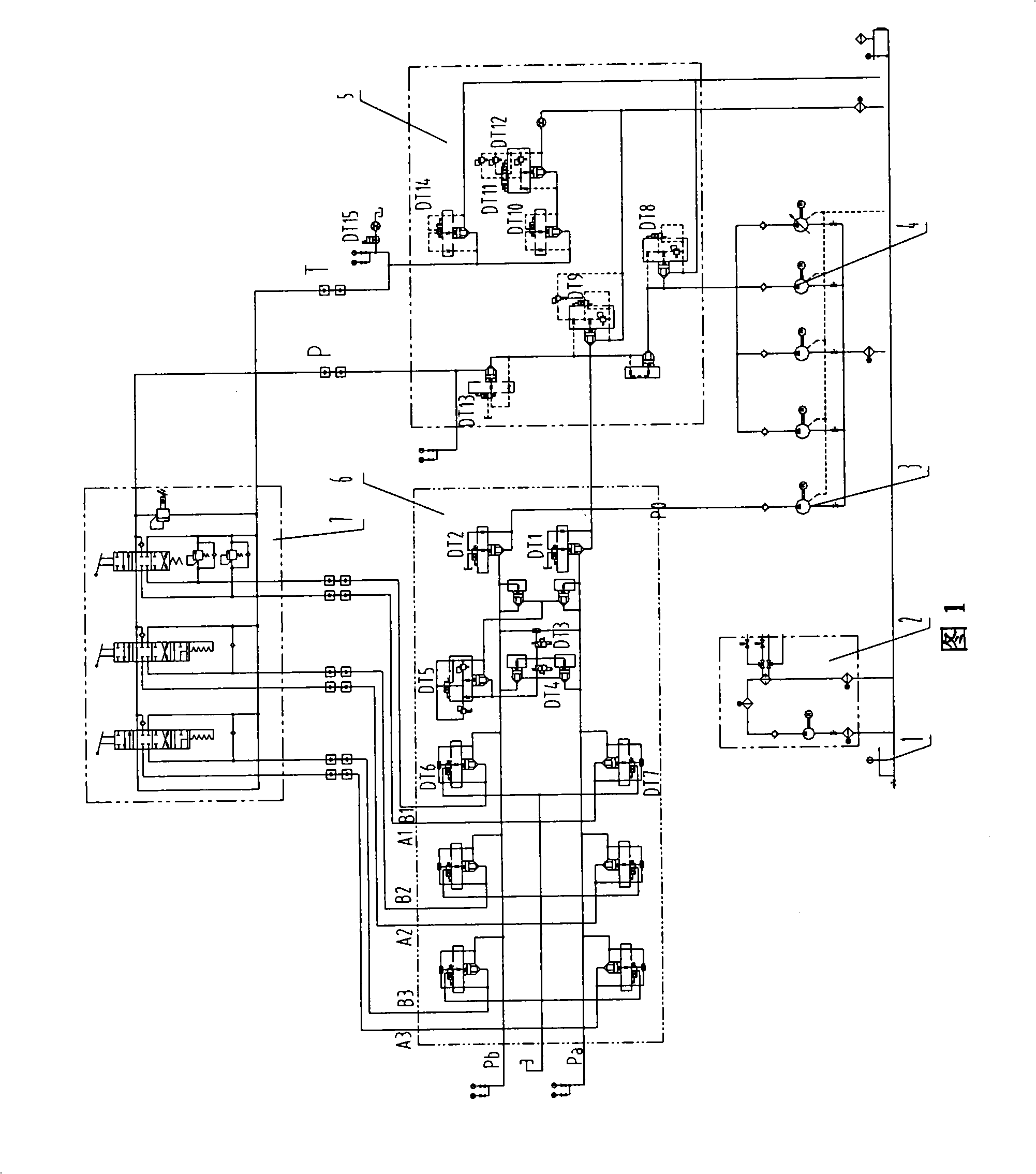

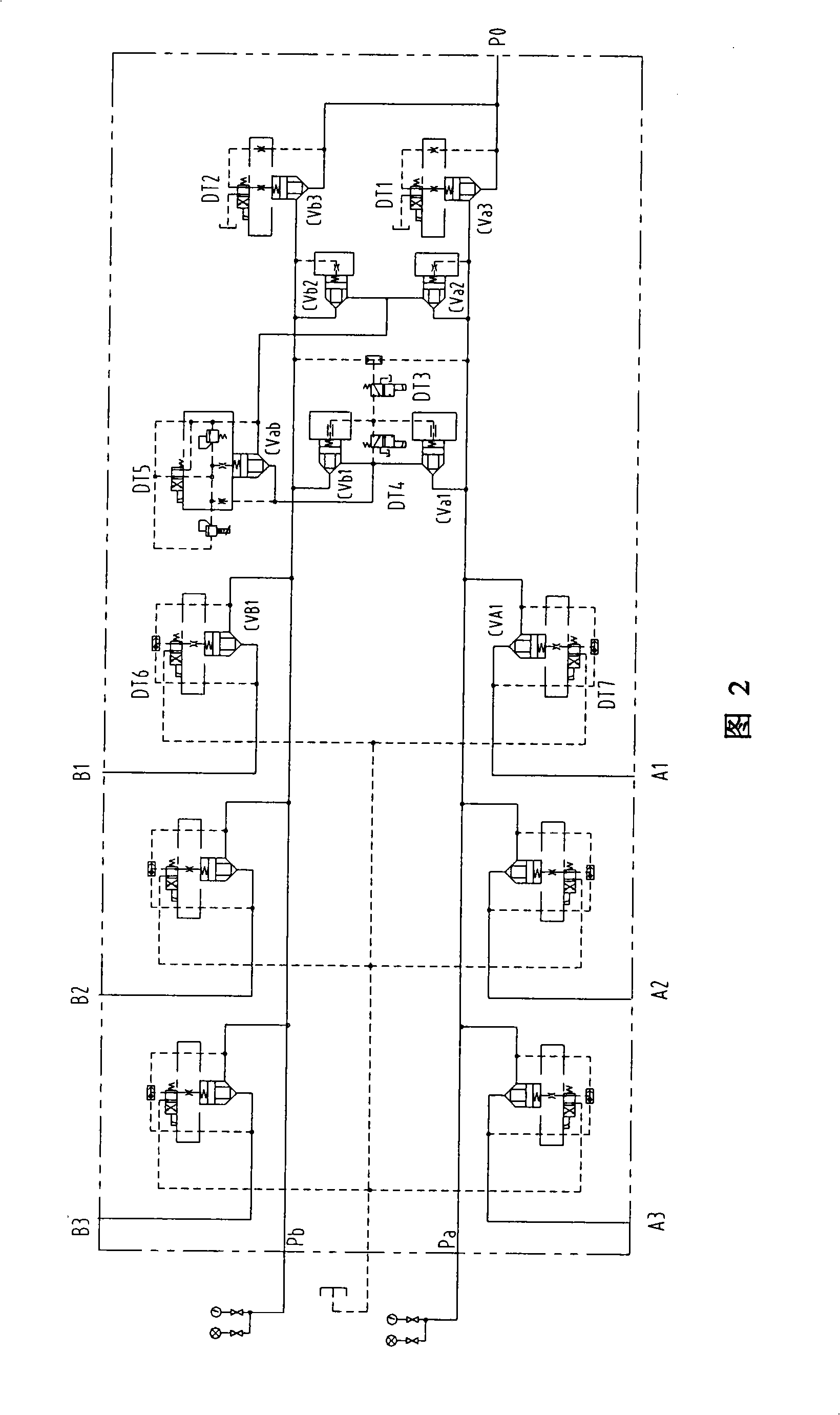

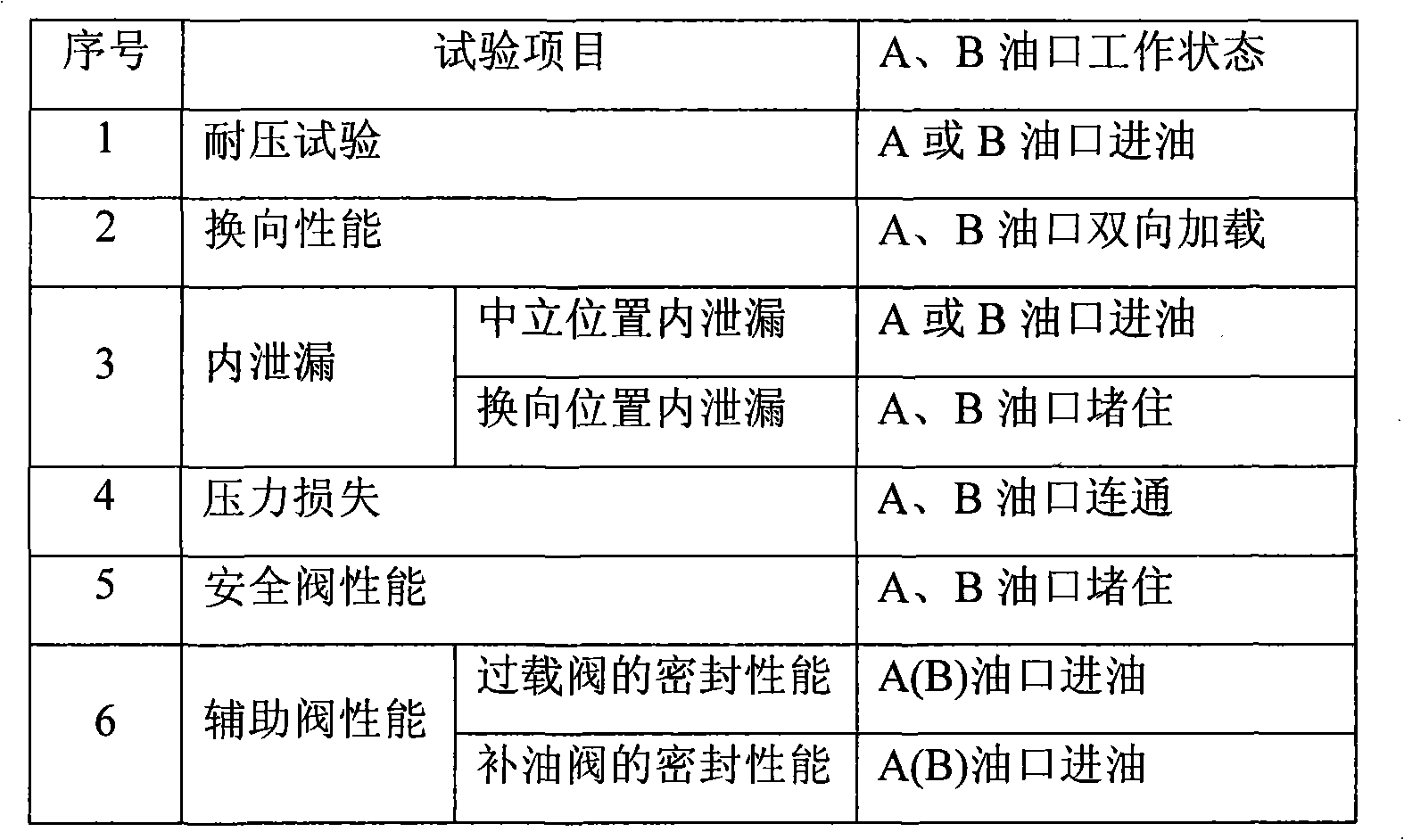

[0023] Control device for oil port test of hydraulic reversing valve, including oil tank 1, filter temperature control device 2, control oil pump motor unit 3, main oil pump motor unit 4, oil inlet and return control valve group 5, oil port test process control bridge 6, replacement to valve 7. The pump station is composed of oil tank, filter temperature control device, main oil pump motor unit and control oil pump motor unit. The function of the oil pump motor unit is to provide pressure oil with a certain pressure and flow rate to the test system. The filtration temperature control system consists of an oil pump motor unit, two-stage filter, plate radiator and control valve to meet the oil cleanliness and test temperature control requirements of the test bench.

[0024] The hydraulic test control system is equipped with pressure gauges, pressure gauge switches, primary measuring instruments, operating force sensors, test piece connection ports and test platforms, etc., which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com