Quantitative sampling and dilution analysis apparatus

A quantitative sampling and dilution analysis technology, which is applied in the direction of sampling devices, test sample preparation, etc., can solve the problem of general products without structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation, structure, features and functions of the quantitative sampling and dilution analysis device according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

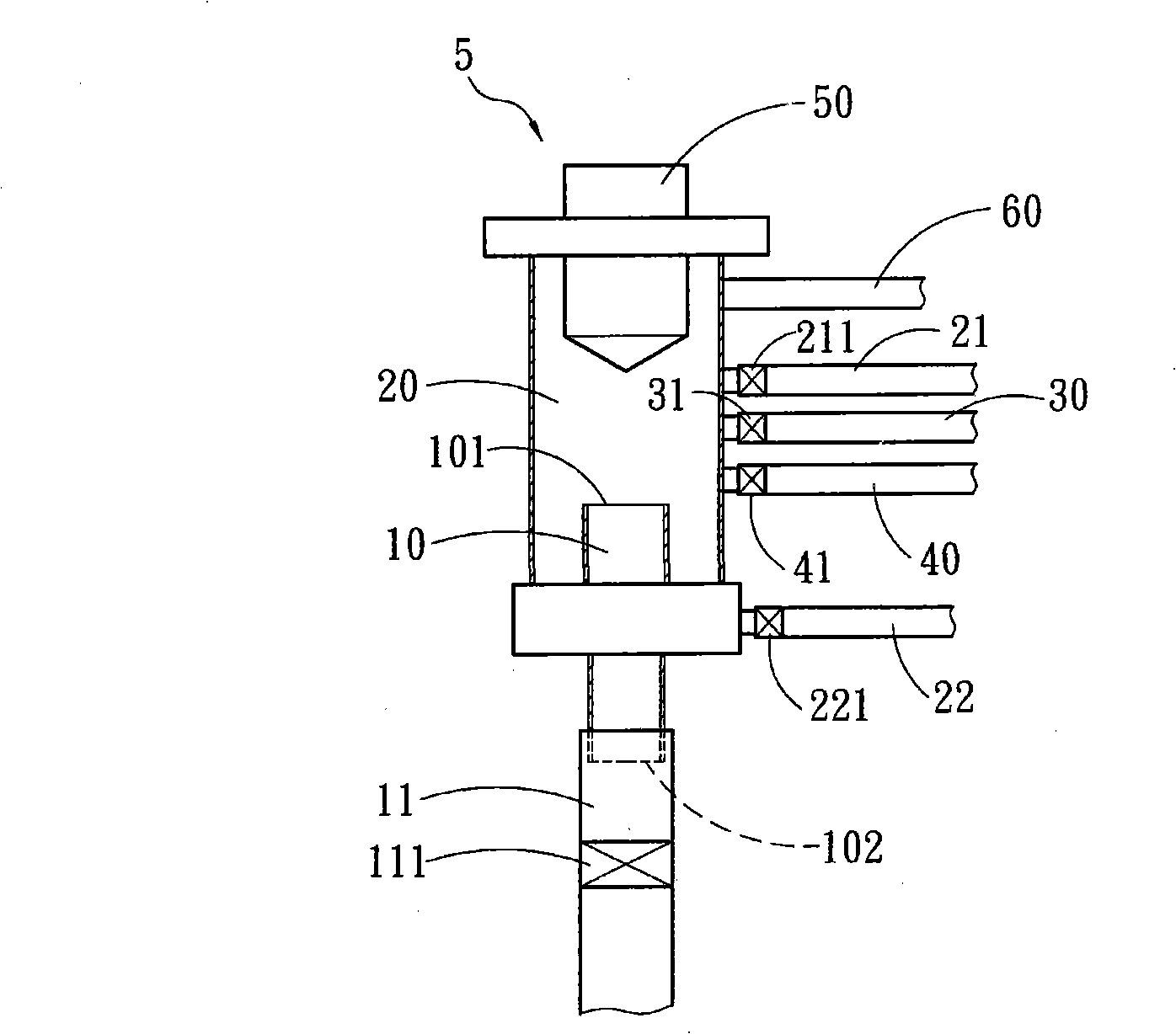

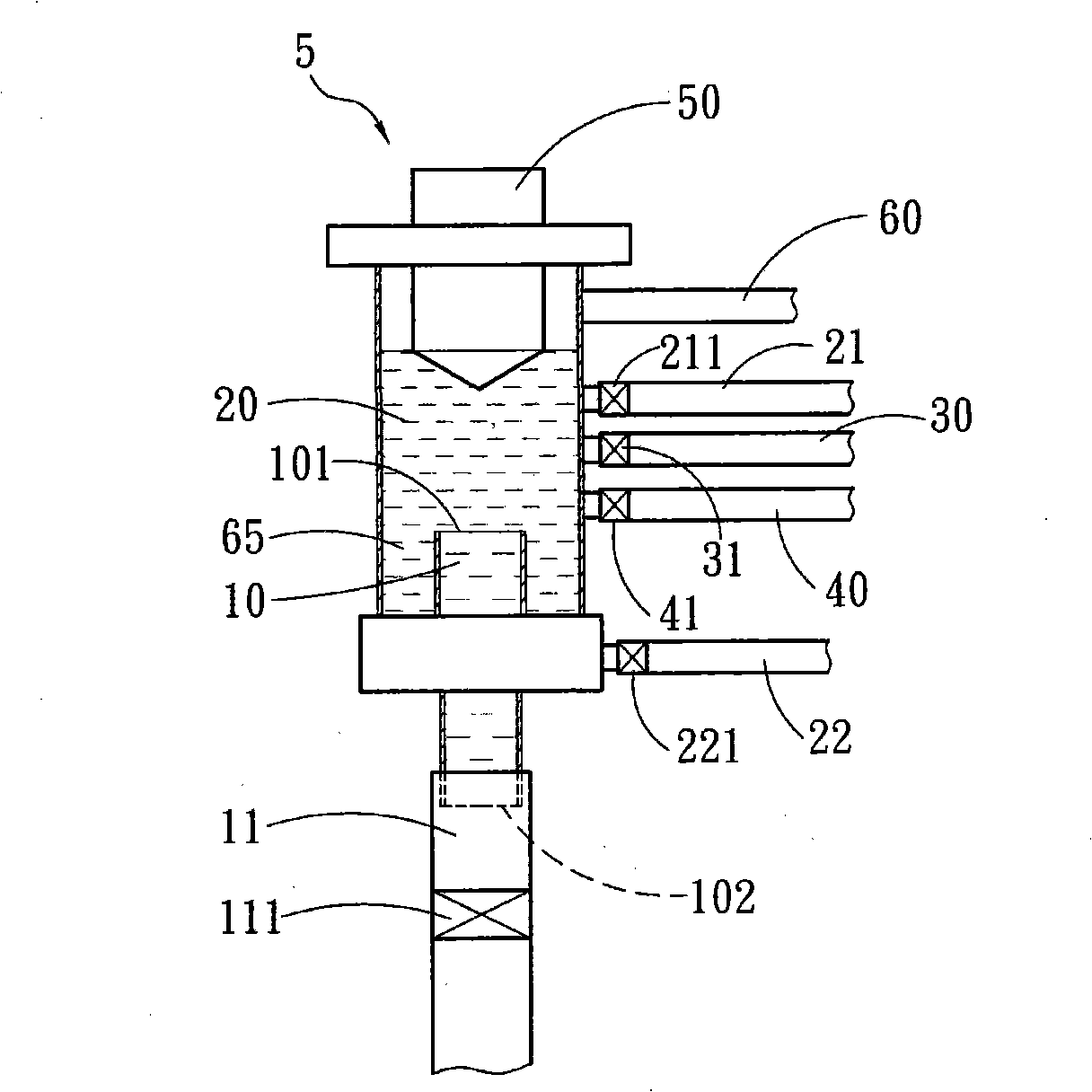

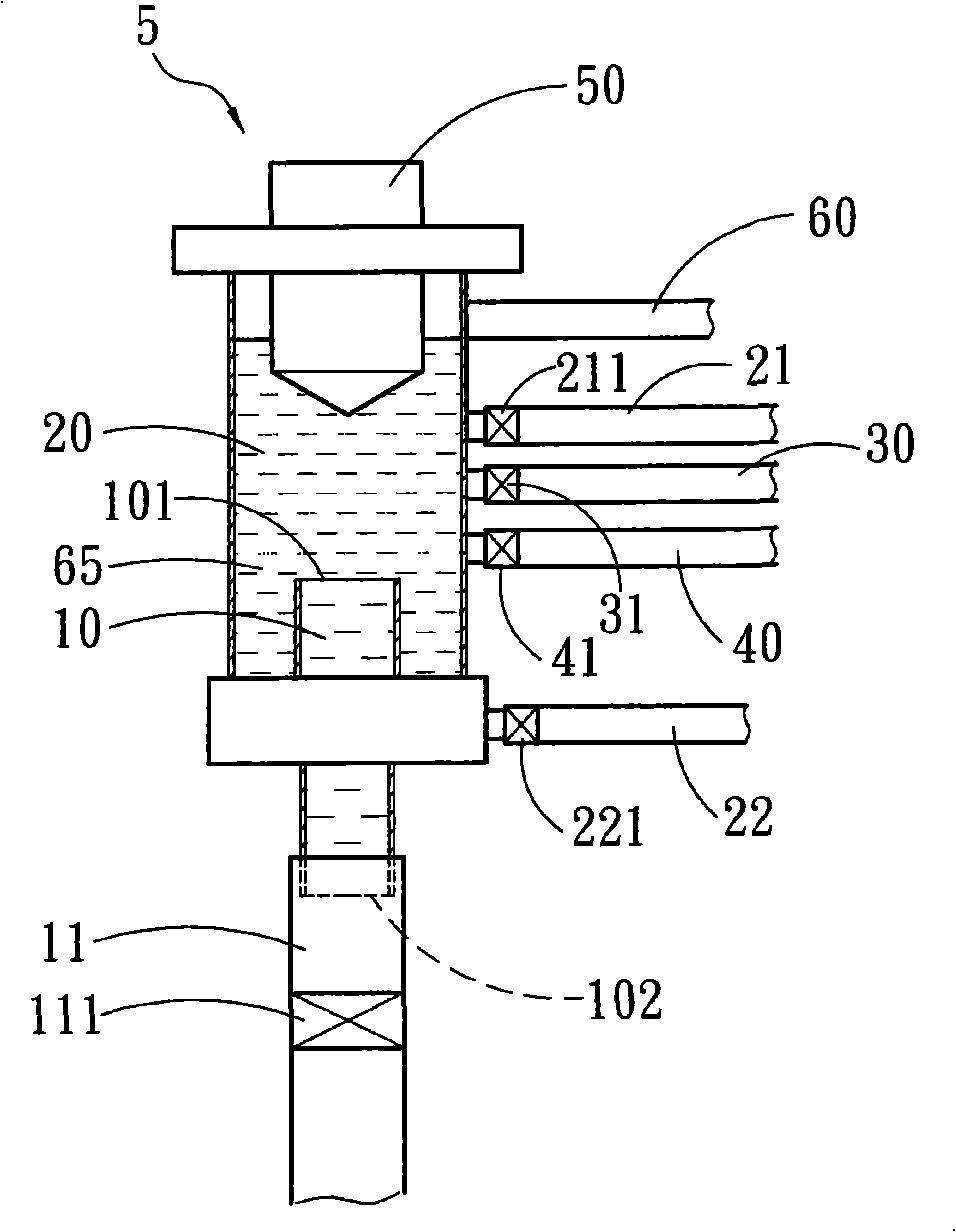

[0042] see figure 1 As shown, the quantitative sampling device 5 of the present invention includes an inner tube 10 and an outer tube 20, the inner tube 10 is arranged in the outer tube 20, and the inner tube 10 is vertically arranged and has a top opening 101 and a The bottom discharge port 102, the bottom discharge port 102 is connected to a water outlet pipeline 11, the water outlet pipeline 11 is provided with a water sample fluid switch 111, and the outer tube 20 is connected to a sampling pipeline 21, and the sampling pipeline 21 is connected to to a production line (not shown), and Let the connection between the outer pipe 20 and the sampling pipeline 21 be higher than the top opening 101 of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com