Double pole plate for fluid flow battery

A liquid flow battery and bipolar plate technology, applied in battery electrodes, fuel cell parts, hybrid batteries, etc., can solve the problems of brittle and brittle dense graphite plates, difficult battery installation process, etc., to promote electrochemical oxidation Reduction reaction, uniform distribution, effect of increasing current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

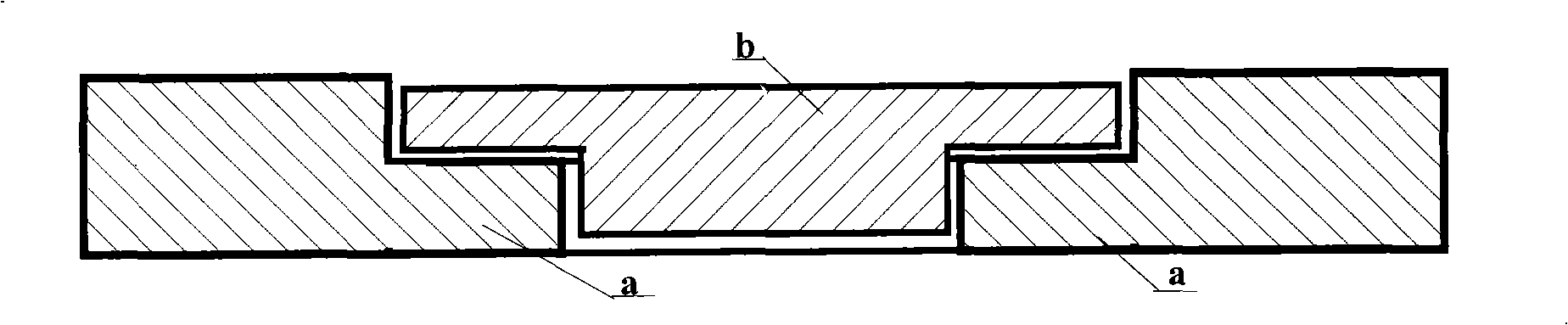

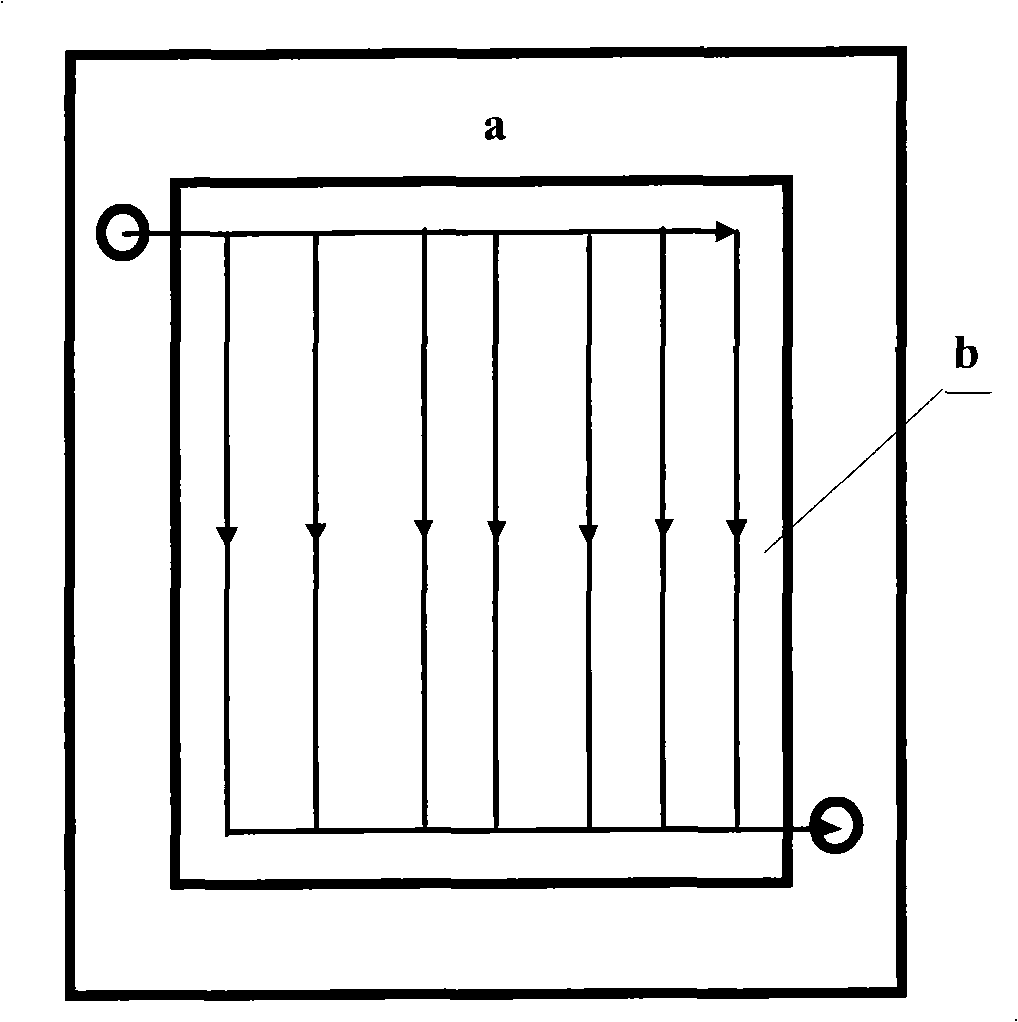

[0023] Embodiment 1: use a polyvinyl chloride engineering plastic plate with a thickness of 10mm, and a dense graphite plate with a thickness of 8mm is embedded in the middle part, and grooves with a depth of 3mm and a width of 3mm can be formed on both sides of the dense graphite plate; polyvinyl chloride engineering The plastic plate and the dense graphite plate are connected in a step-like manner, and the width of the contact surface is 10mm. The diversion grooves with the same shape on the front and rear sides of the dense graphite plate are composed of a main flow channel and parallel parallel branch flow channels connected to each other, and finally they are classified into the same main flow channel to allow the electrolyte to flow out ( figure 2 shown). Use polyvinyl chloride board bonding glue to bond the two.

Embodiment 2

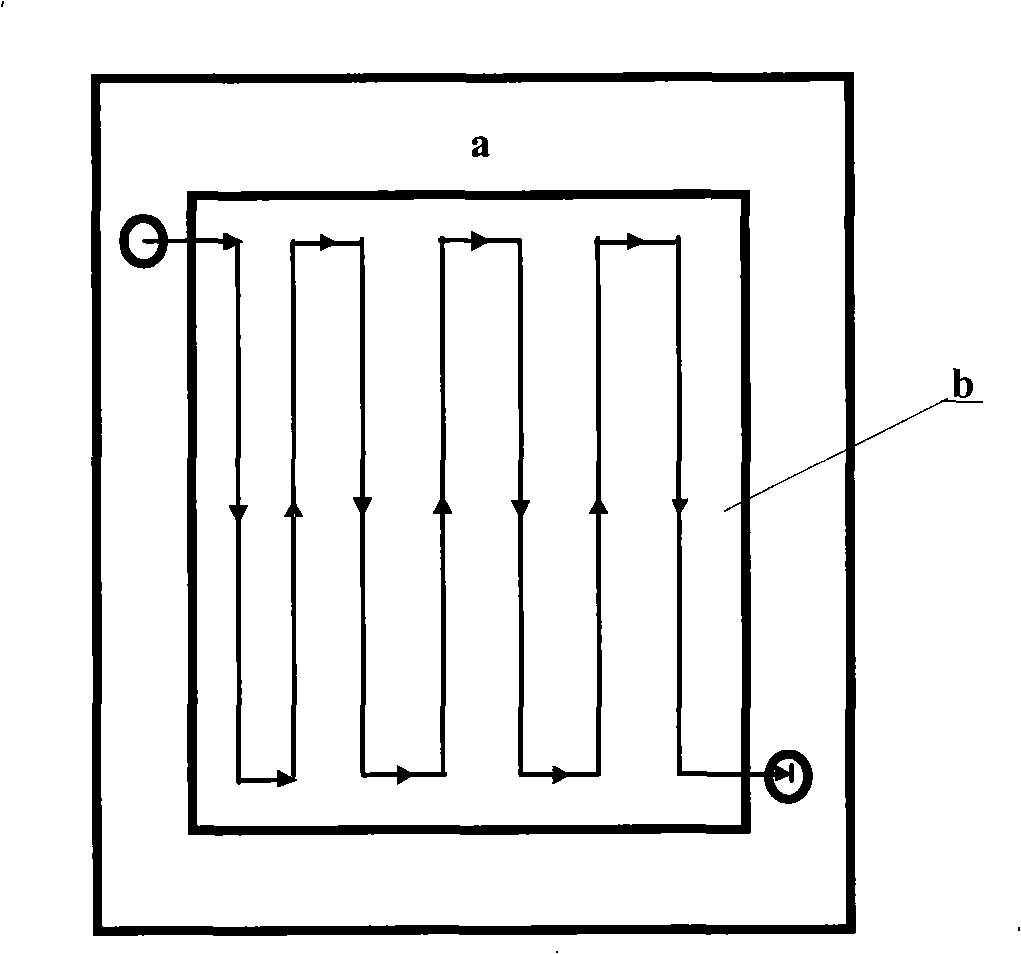

[0024] Embodiment 2: Use a polyvinyl chloride engineering plastic plate with a thickness of 10mm, and a dense graphite plate with a thickness of 8mm is embedded in the middle part, and electrolyte diversion grooves are engraved on both sides of the dense graphite plate; polyvinyl chloride engineering plastic The plate and the dense graphite plate are lapped, and the width of the contact surface is 12mm. The diversion grooves with the same shape on both sides of the dense graphite plate are composed of a meandering flow channel, the depth of the flow channel is 3 mm, and the width is 5 mm ( image 3 shown). Use polyvinyl chloride board bonding glue and epoxy resin adhesive to bond the two.

Embodiment 3

[0025] Embodiment three: use a polyvinyl chloride engineering plastic plate with a thickness of 10 mm, and insert a dense graphite plate with a thickness of 8 mm in the middle part, and electrolyte diversion grooves are engraved on both sides of the dense graphite plate; polyvinyl chloride engineering plastic The plate and the dense graphite plate are lapped, and the width of the contact surface is 12mm. The diversion grooves with the same shape on the front and rear sides of the dense graphite plate are composed of a combination of series connection and parallel connection. The depth of the flow channel is 3mm, and the width is 3mm ( Figure 4 shown). Use PVC board bonding glue and epoxy adhesive to bond the two.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap