Three-phase winding Y-wiring single phase capacitance run motor for washing machine

A three-phase winding, washing machine technology, applied to asynchronous induction motors, electromechanical devices, shapes/styles/structures of winding conductors, etc., can solve problems such as difficult to obtain performance, difficult design adjustment, complex magnetic circuits and circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

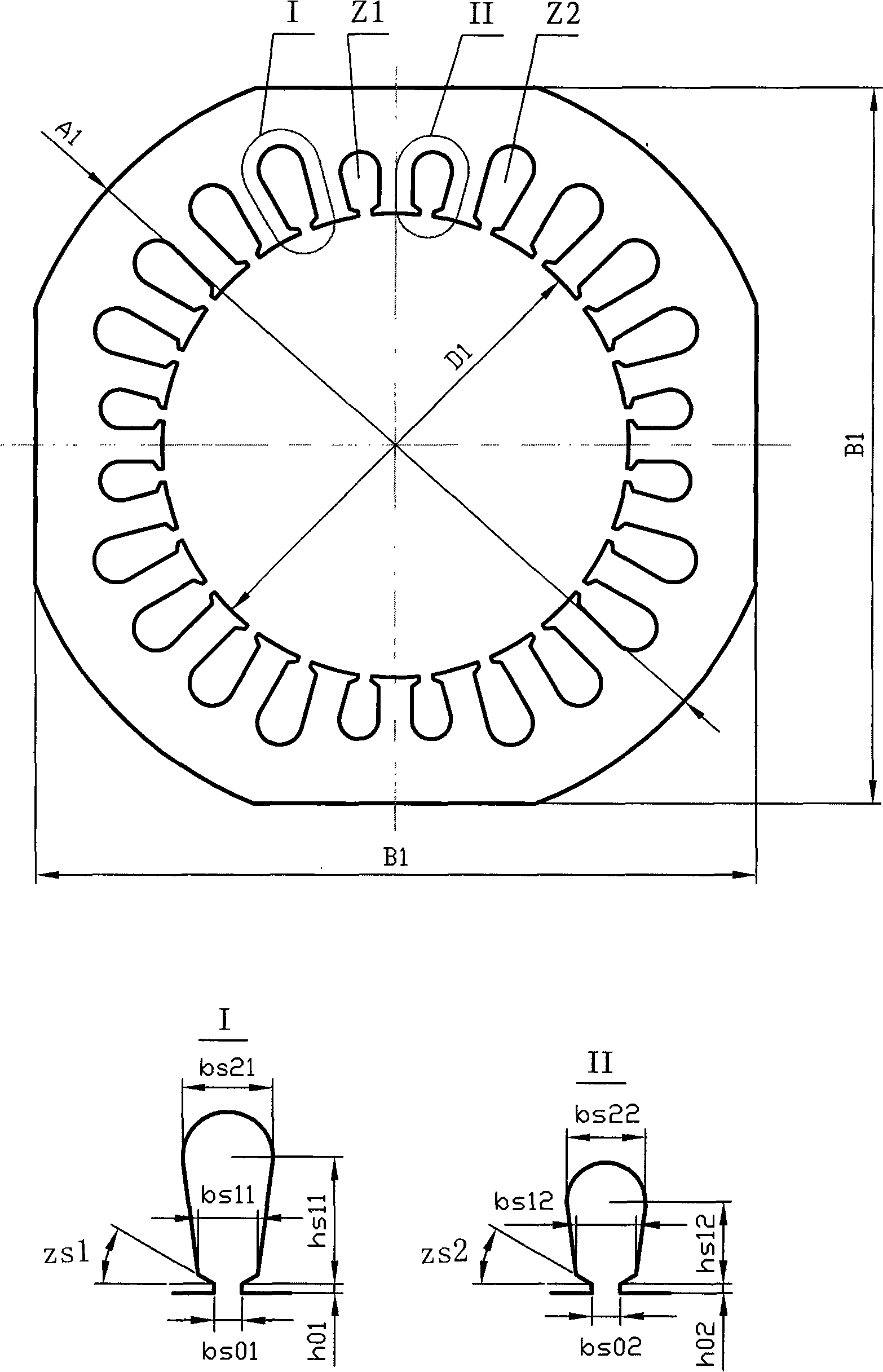

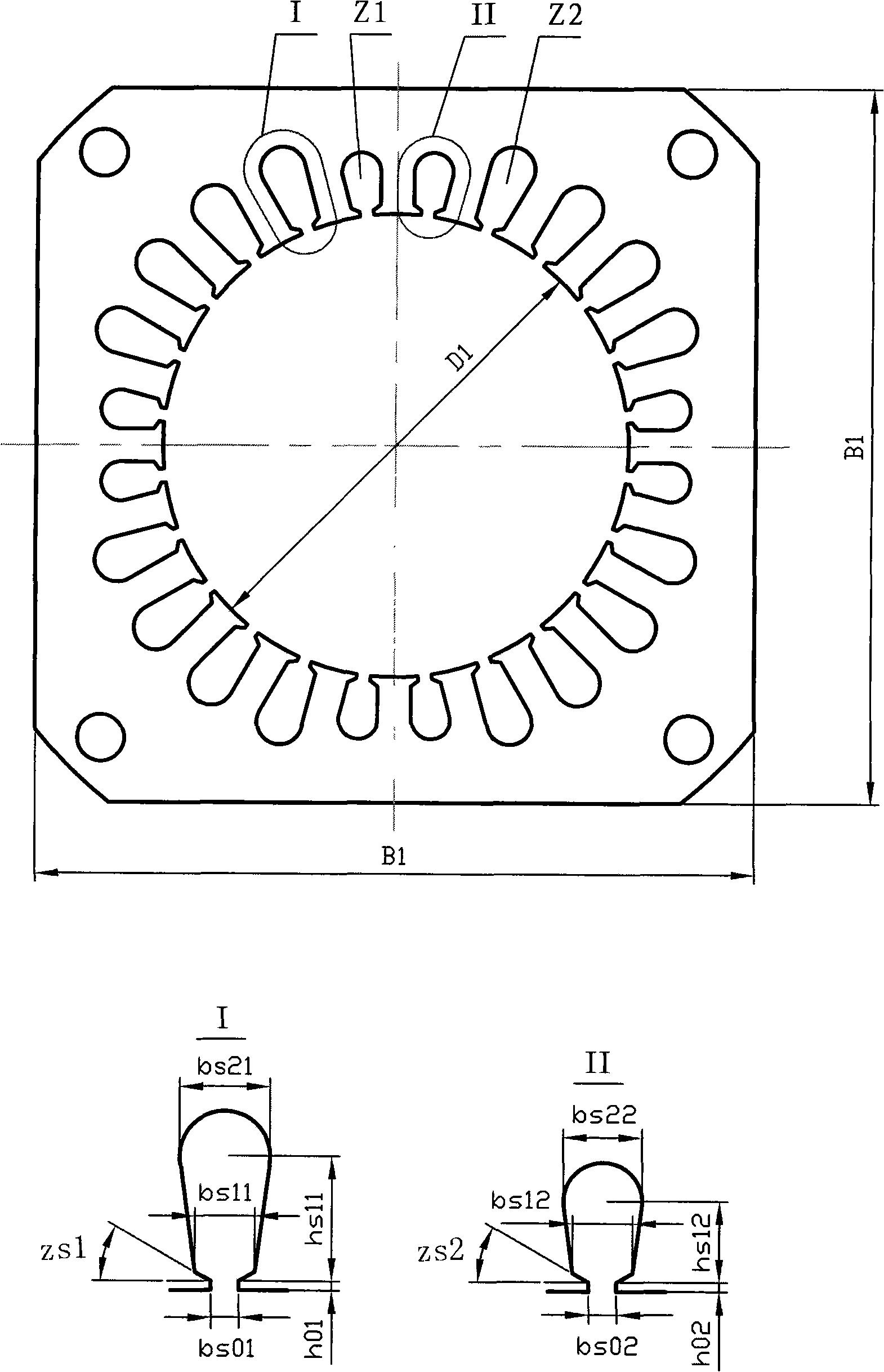

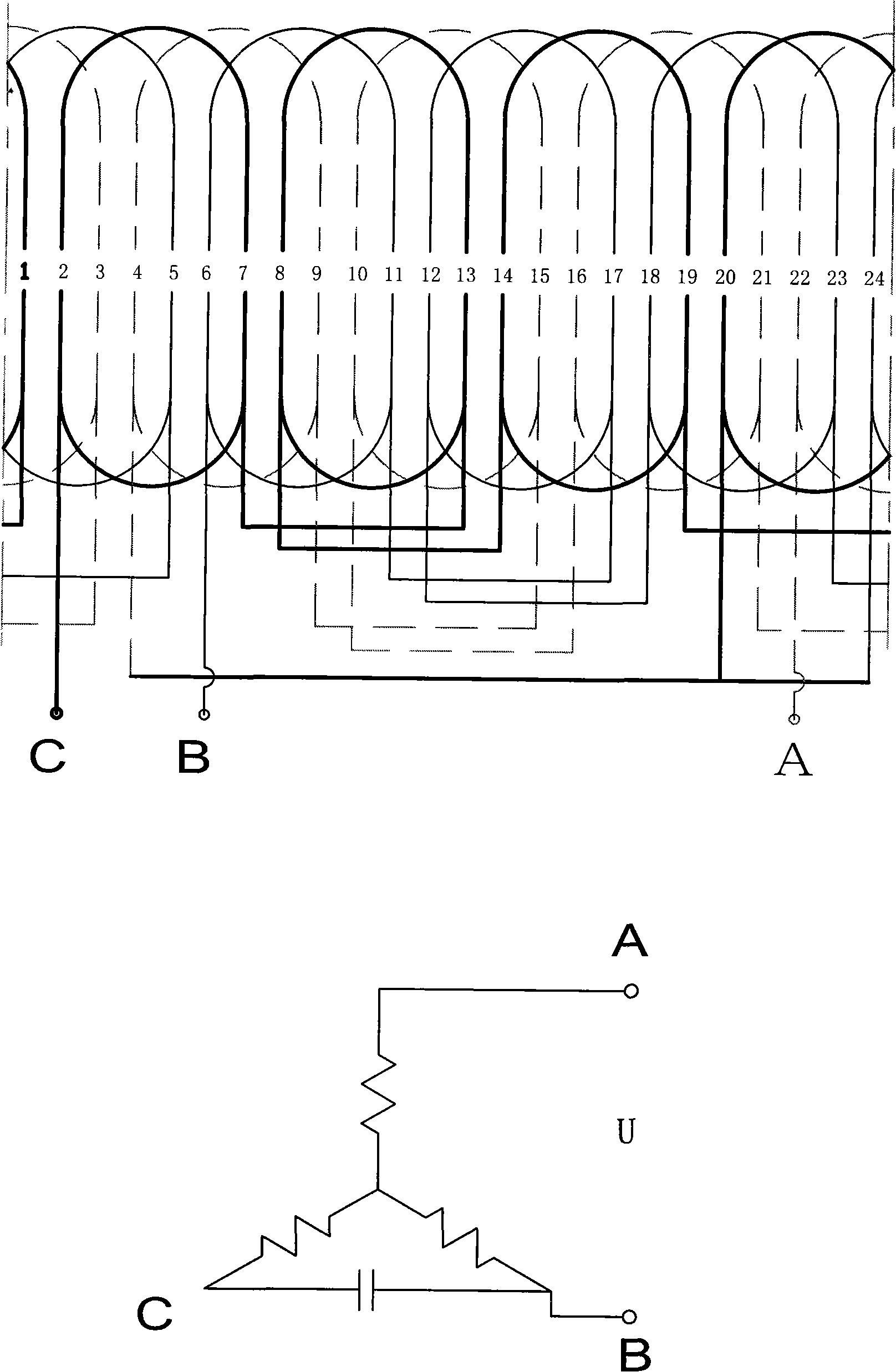

[0012] The embodiment of the present invention washing machine is used single-phase electric capacity to operate the electric motor stator punching sheet such as figure 1 or figure 2 As shown, the winding distribution and wiring are as image 3 shown. It is based on a single-phase capacitor running motor for washing machines (rated voltage 220V, frequency 50Hz, output power 140W, speed 1325r / m; capacitor capacity 12μF) in the prior art that meets the requirements of the national industry standard JB / T3758. It is designed by modifying its stator core and winding.

[0013] The motor of the embodiment of the present invention follows the structure of the prior art. The motor includes:

[0014] --See figure 1 , the square size of the stator punching sheet B1=108mm (the cutting situation will cause the design value of B1 to have a difference of ±1mm), the diameter of the 4-corner arc A1=114mm, the inner diameter D1=70mm; 24 grooves with round bottom grooves, parallel teeth and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com