Infantile nutrition maize flour and preparation thereof

A technology of corn flour and infants, applied in the field of infant nutrition corn flour and its preparation, can solve the problems of not suitable for the nutritional needs of infants, corn flour not suitable for infants to improve nutritional structure, low trace elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

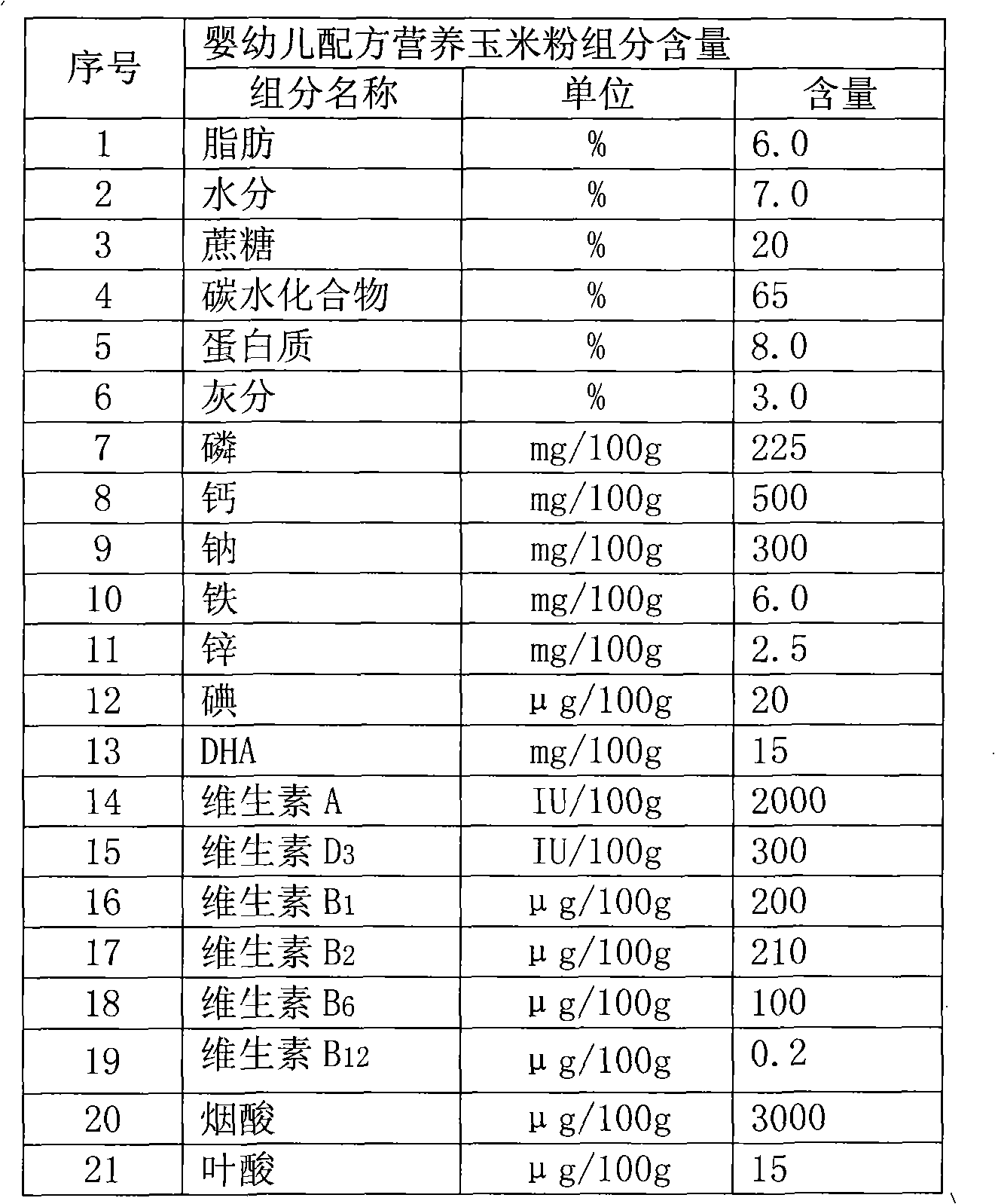

[0009] Thresh the fresh and tender sweet corn, precook at 60°C, freeze at -24°C, and ultrafinely pulverize with 300 meshes, add sugar, salt, auxiliary materials, and additives at 70°C for slurry preparation, concentrate the slurry to 70%, and heat up after passing through a colloid mill Pregelatinize at 70°C for 15 minutes, and then dry in a drum desiccant. Dryer setting parameters: surface temperature 120°C, material temperature 85°C, air pressure 0.30Mpa, speed 40Hz. Finally the dry material is ground and fortified blended. Gained above-mentioned product component content is as shown in the table.

[0010]

Embodiment 2

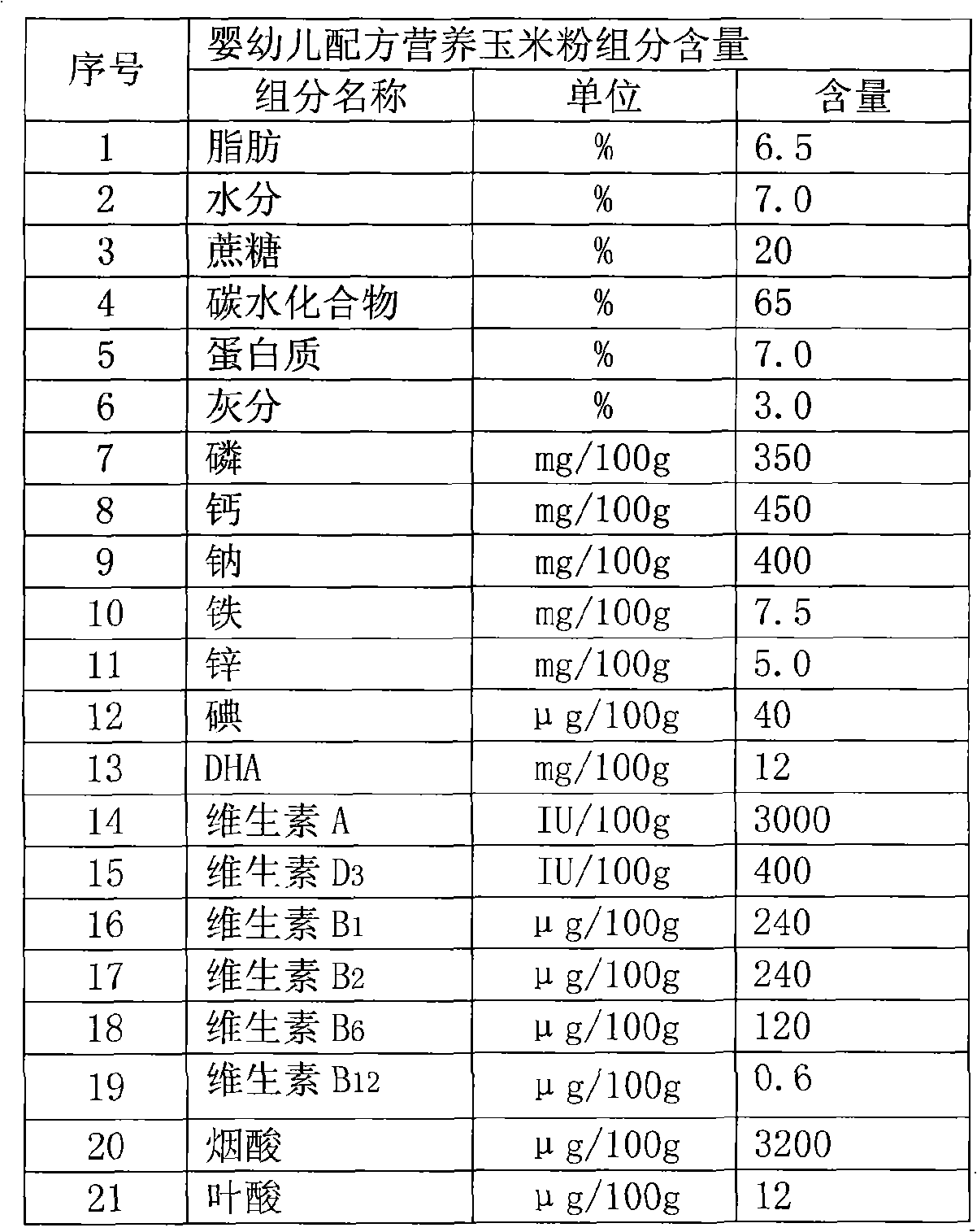

[0012] Thresh the fresh and tender sweet corn, precook at 70°C, freeze at -24°C and then grind it into a 300-mesh ultrafine powder, add sugar, salt, auxiliary materials and additives to prepare the slurry at 80°C, concentrate the slurry to 75%, pass through a colloid mill and then heat up Pregelatinize at 80°C for 12 minutes, and then dry in a drum desiccant. Dryer setting parameters: surface temperature 130°C, material temperature 85°C, air pressure 0.25Mpa, speed 38Hz. Finally the dry material is ground and fortified blended. Gained above-mentioned product component content is as shown in the table.

[0013]

Embodiment 3

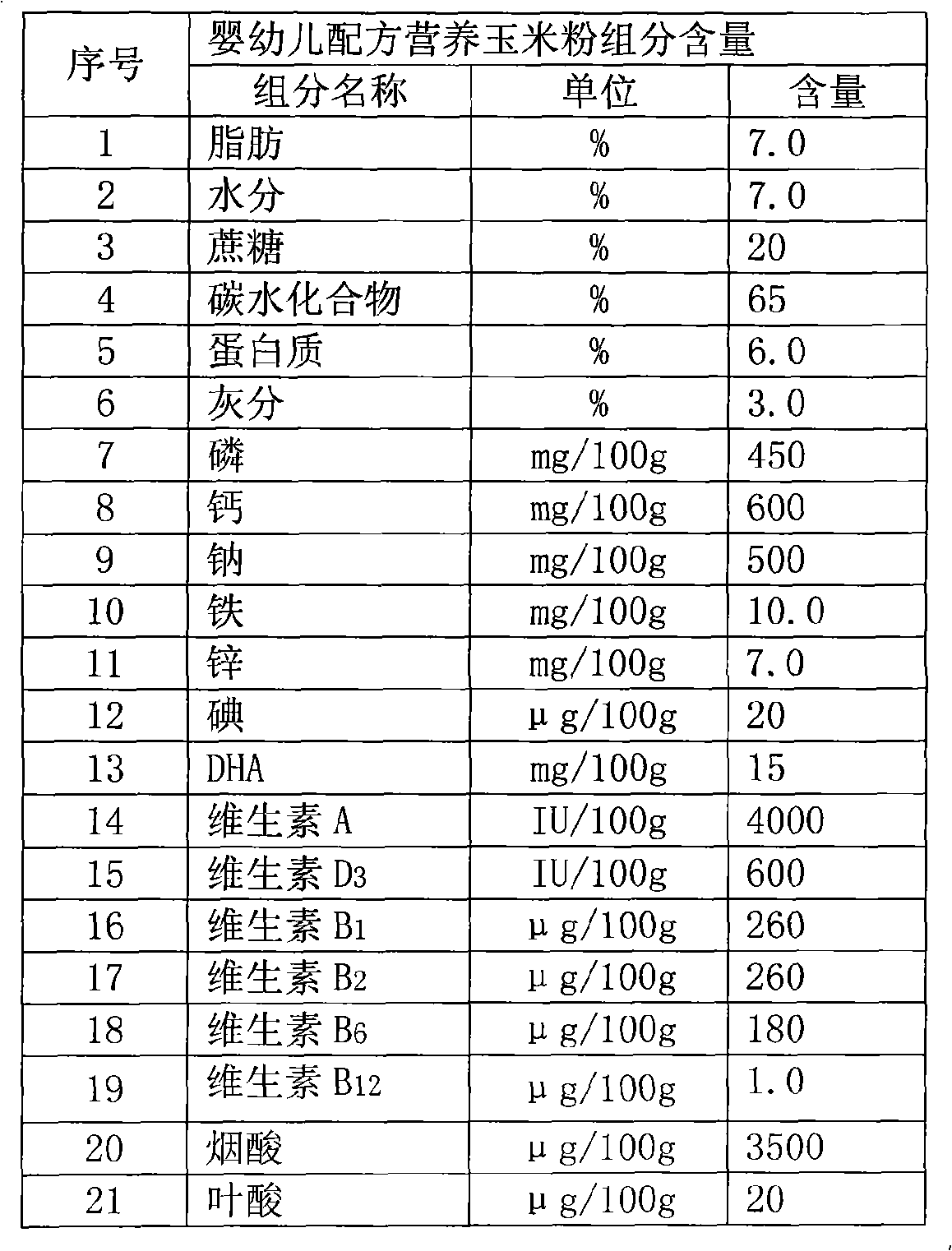

[0015] Thresh the fresh and tender sweet corn, precook at 80°C, freeze at -24°C, and ultrafinely pulverize with 200 meshes, add sugar, salt, auxiliary materials, and additives to make slurry at 80°C, concentrate the slurry to 80%, and heat up after passing through a colloid mill Pregelatinize at 90°C for 10 minutes, and then dry in a drum desiccant. Dryer setting parameters: surface temperature 140°C, material temperature 95°C, air pressure 0.30Mpa, speed 44Hz. Finally the dry material is ground and fortified blended. Gained above-mentioned product component content is as shown in the table.

[0016]

[0017] In summary, the present invention uses fresh sweet corn as the main raw material, and finally grinds the dry material made from fresh sweet corn as the main raw material and adds appropriate amounts of calcium, iron, zinc, sodium, iodine, DHA, vitamin A , Vitamin D 3 , Vitamin B 1 and vitamin B 2 Make a nutritionally fortified blend.

[0018] In order to make the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com