Low nickle type austenitic stainless steel and manufacturing method thereof

A technology of austenitic stainless steel and manufacturing method, which is applied in the field of alloys, can solve the problems of reducing corrosion resistance, lowering the corrosion resistance elements, affecting the rolling yield, etc., and achieves the effect of improving corrosion resistance and preventing edge crack defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

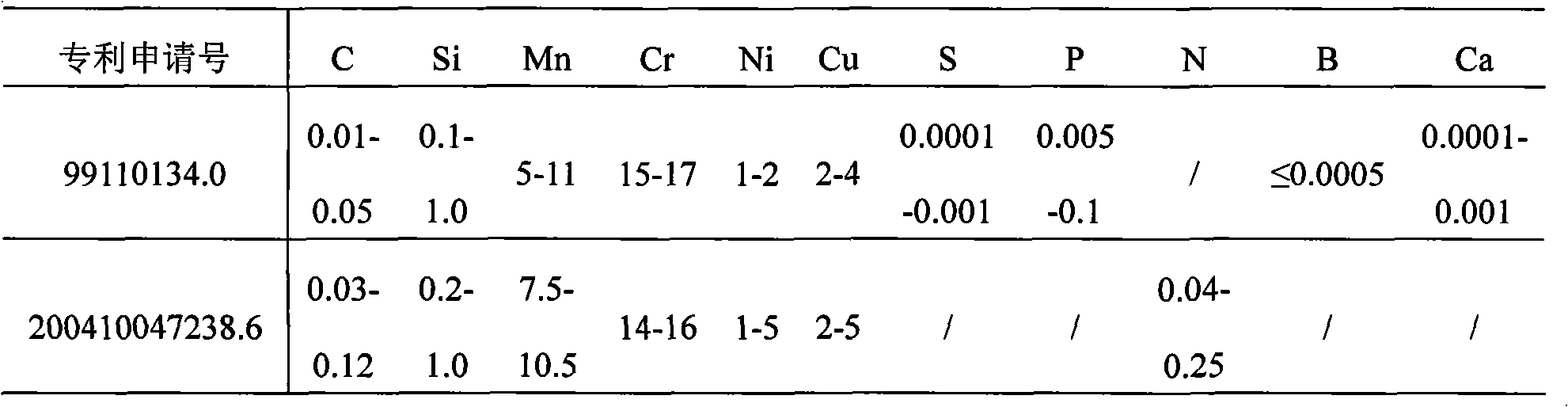

[0051] Alloys with the chemical composition shown in Table 2 are smelted and cast, and then subjected to hot rolling, hot strip annealing and pickling, cold rolling and cold strip annealing and pickling with a reduction of at least 50%. Among them, the hot-rolled coil process parameters, heat treatment parameters, cold treatment parameters and edge cracks are shown in Table 7, and the mechanical properties after cold working are shown in Table 8.

[0052] Table 2 Chemical Composition (%)

[0053]

Embodiment 2

[0055] According to the ratio of the chemical components shown in Table 3, the operation was carried out according to the process steps described in Example 1. Among them, the hot-rolled coil process parameters, heat treatment parameters, cold treatment parameters and edge cracks are shown in Table 7, and the mechanical properties after cold working are shown in Table 8.

[0056] Table 3 Chemical Composition (%)

[0057]

Embodiment 3

[0059] According to the ratio of the chemical components shown in Table 4, the process steps described in Example 1 were used. Among them, the hot-rolled coil process parameters, heat treatment parameters, cold treatment parameters and edge cracks are shown in Table 7, and the mechanical properties after cold working are shown in Table 8.

[0060] Table 4 Chemical Composition (%)

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com