Electrostatic spinning machine having special reticulate pattern electrode and use method thereof

An electrospinning machine and net pattern technology, which is applied in the field of high-efficiency electrospinning membrane-making devices, can solve problems such as difficult preparation of high-strength nanofiber membranes, and achieve the effect of low mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

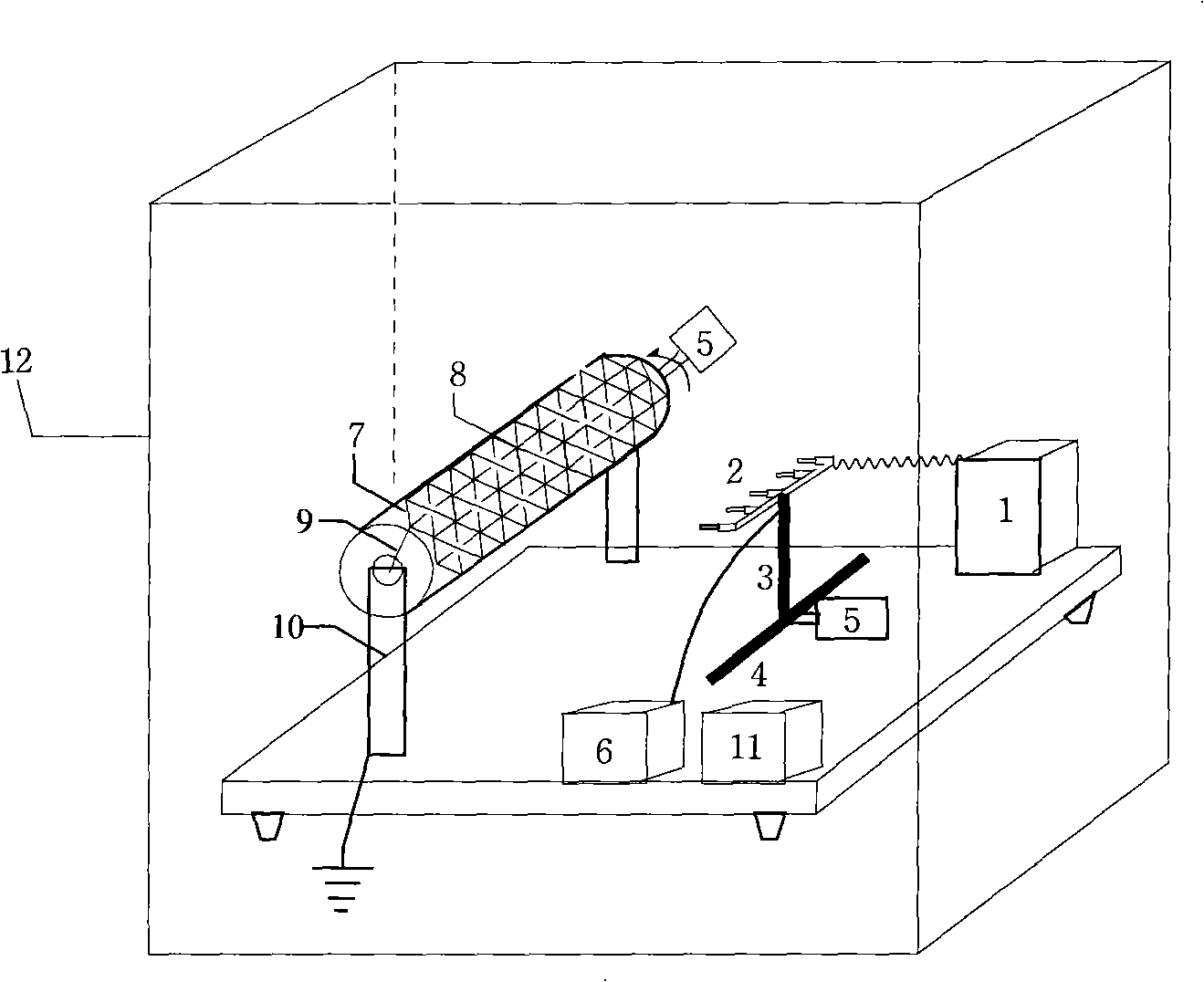

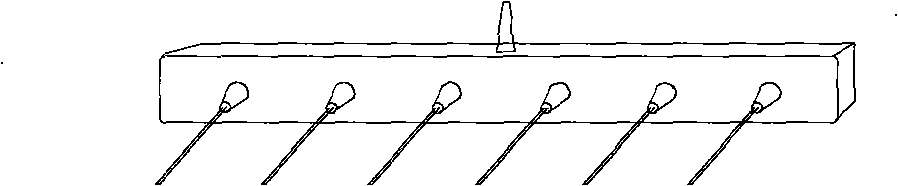

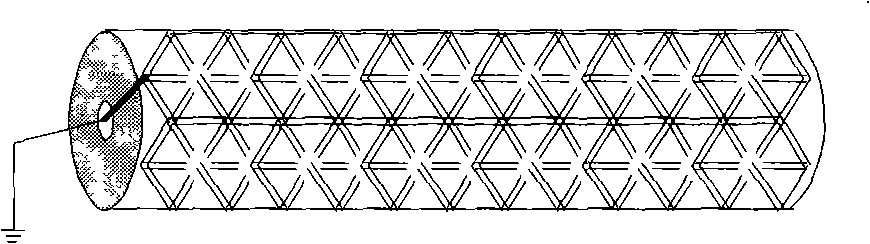

[0036] See Figure 1~3 . An electrospinning machine with temperature control device 12 and mechanical control device 11 (such as figure 1 shown), the multi-needle nozzle 2 of the electrospinning machine (such as figure 2 As shown) is connected to the high-voltage output of one end of the high-voltage DC power supply 1 through a high-voltage wire, and the feed hole of the multi-needle spinneret is connected with the metering infusion pump 6 through a pipeline; The engineering plastic receiving roller 7 on the top, the engineering plastic receiving roller 7 has a motor 5, and the surface of the receiving roller is embedded with a special textured copper electrode 8 (such as image 3 shown); the multi-needle nozzle is at the same height as the horizontal axis of rotation of the receiving roller; the extended copper wire 9 of the anilox copper electrode on the surface of the receiving roller is connected to the special ground wire through the wire and is effectively grounded. ...

Embodiment 2

[0042] Preparation weight concentration is the polyvinylpyrrolidone (PVP) ethanol solution of 11%, the viscosity of solution is between 300~400mPa S, stirs 3 days at 25 ℃, adopts the electrospinning machine of embodiment 1, single row of multi-needle nozzles Horizontal reciprocating scanning spraying. Set the rotational speed of the receiving roll to be 30cm / min, the distance between the spinneret and the receiving roll to be 8-10cm, the applied electric field strength to be 1-1.2kV / cm (voltage 8-12kV), and the moving speed of the spinneret to be 40-45cm / min, the solution delivery speed is 8mL / h per needle. Turn on the high-voltage power supply, the drive motor of the receiving roller, the metering infusion pump and the drive motor of the multi-needle nozzle, the operating environment temperature is 30°C, the spraying time is 30 minutes, and the spraying volume is controlled to 36m 2 / h. Obtain uniform polyvinylpyrrolidone nanofiber film on the receiving roll surface, its su...

Embodiment 3

[0044] The structure of the electrospinning machine with special mesh electrodes is the same as that in Example 1.

[0045] Prepare a polyvinyl alcohol ethanol solution with a weight concentration of 8.2%, the solution viscosity is between 600-700mPa·S, stir at 25°C for 3 days, and use a single row of multi-needle nozzles for horizontal reciprocating scanning and spraying. Set the rotational speed of the receiving roller to 60cm / min, the distance between the nozzle and the receiving roller to be 8-10cm, the applied electric field strength to be 1.2-1.5kV / cm (voltage 10-15kV), and the moving speed of the spinneret to be 40-45cm / min, the solution delivery rate is 15mL / h per needle. Turn on the high-voltage power supply, the drive motor of the receiving roller, the metering infusion pump and the driving motor of the multi-needle nozzle, the operating environment temperature is 40°C, the spraying volume is set to 48mL / h, and the spraying time is 15 minutes, and a uniform white po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com