Drill pipe sleeve assembly for rotary drilling rig

A technology for rotary drilling rigs and drill pipe pipes, which is applied to drill pipes, drill pipes, casings, etc., can solve the problems of labor-intensive, high operator requirements, high mechanical requirements, etc., to save operation steps, stable and reliable quality, Excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

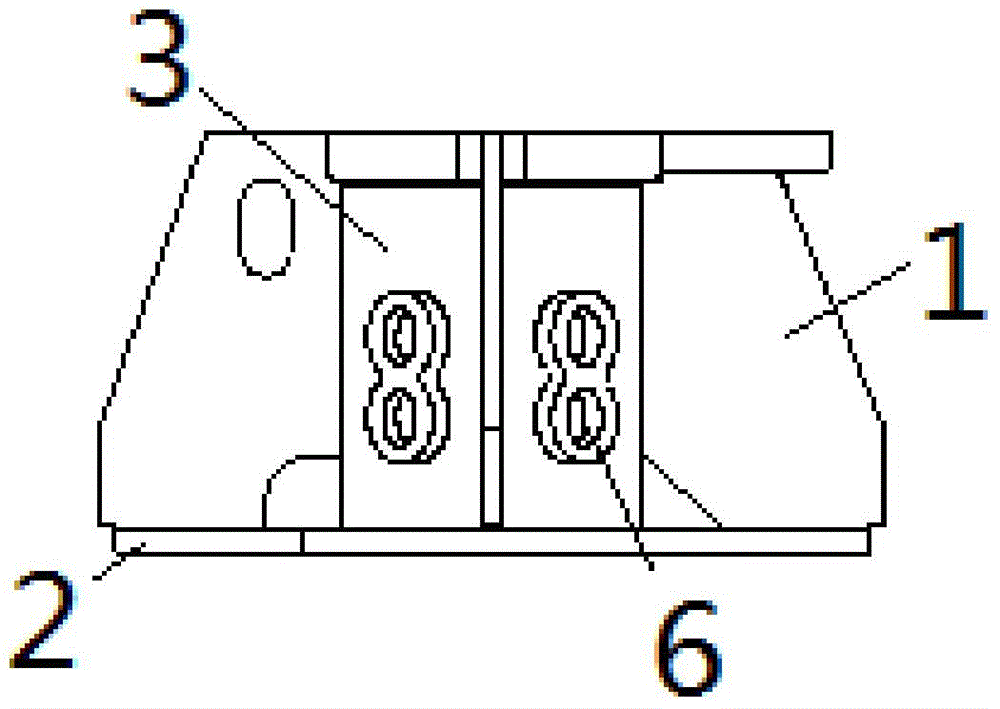

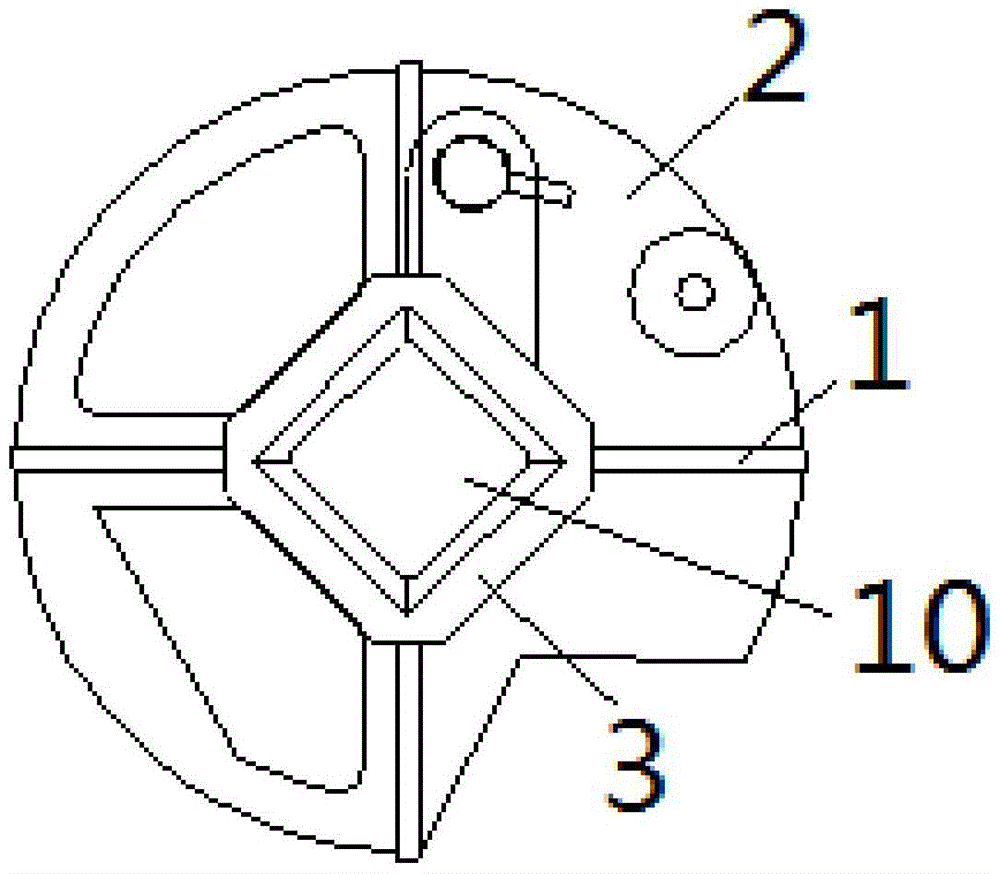

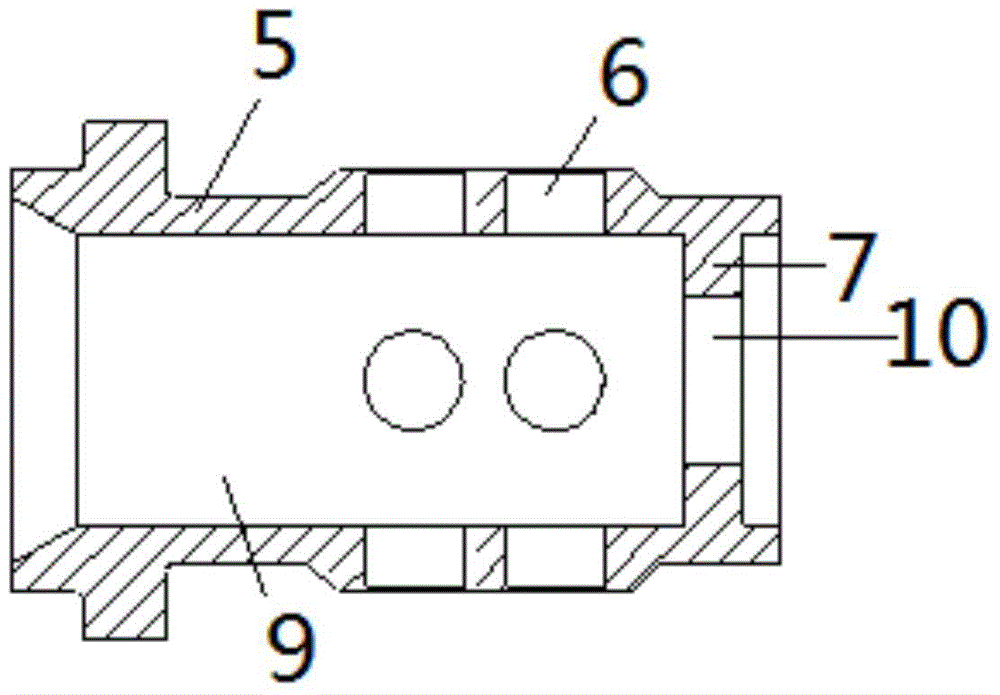

[0020] See Figure 1 to Figure 3 , a drill pipe sleeve assembly for a rotary drilling rig, comprising a drill pipe sleeve 3, a supporting plate 2 connecting the bottom of the drill pipe sleeve 3, and four reinforcing plates 1 respectively connecting the drill pipe sleeve 3 and the supporting plate 2, The drill pipe sleeve 3, the supporting plate 2 and the four reinforcement plates 1 are integrally cast and formed, and the drill pipe sleeve 3 includes the drill pipe sleeve body 5 and two pins that cover the drill pipe 9 of the rotary drilling rig , the drill pipe sleeve body 5 of the rotary drilling rig is in the shape of a square column, and the four sides of the drill pipe sleeve body 5 of the rotary drilling rig are provided with two through holes 6 for pins to pass through. The top of 5 is provided with a square abutment plate 7 against the drill pipe 9 of the rotary drilling rig. The square abutment plate 7 is integrated with the drill pipe sleeve body 5, and the middle pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com