Die for fabricating light wall board and use method thereof

A light-weight wallboard and mold technology, which is applied to building construction, formwork/formwork/work frame, and on-site preparation of building components. Effect of production cost, improvement of competitiveness, and simplification of manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

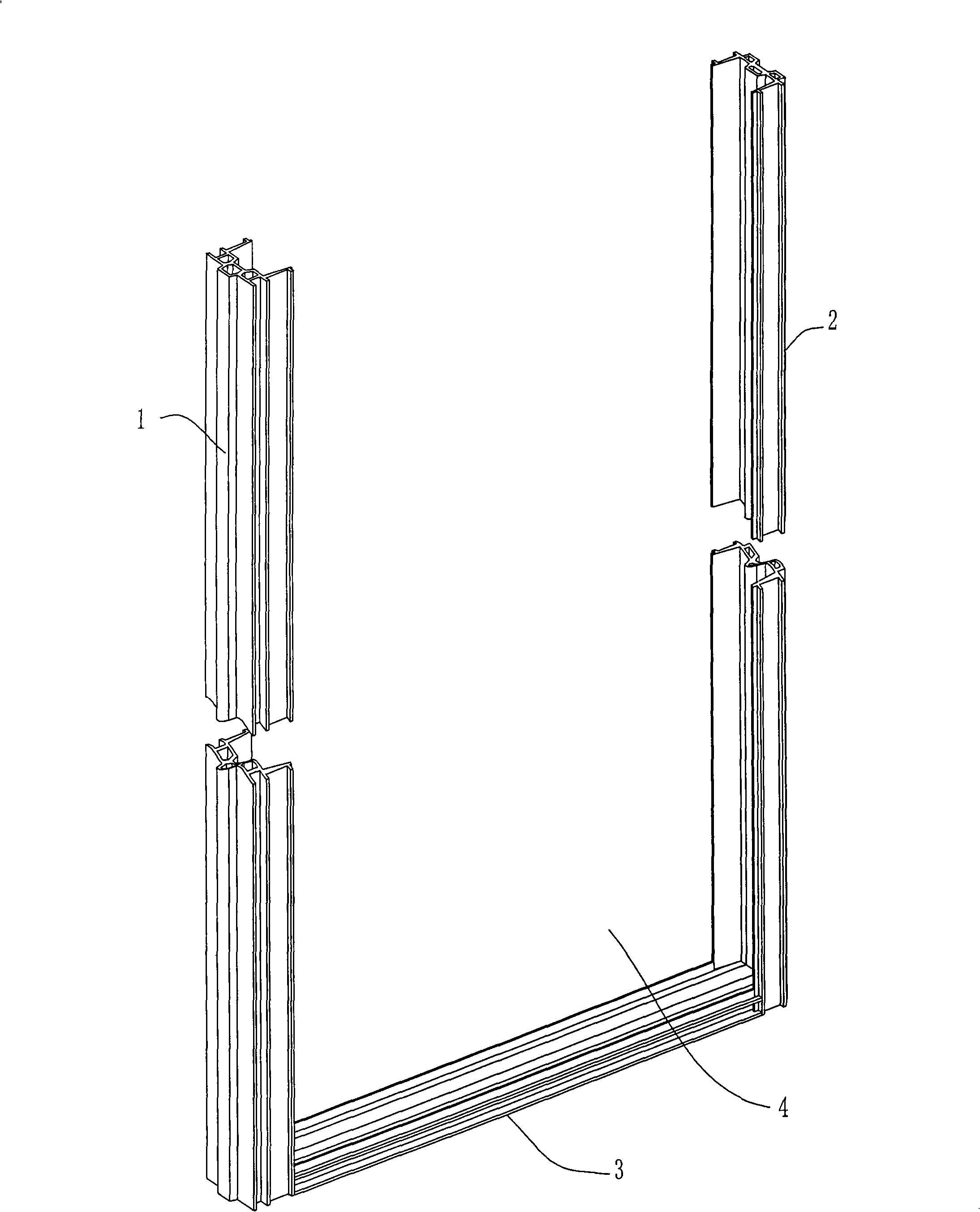

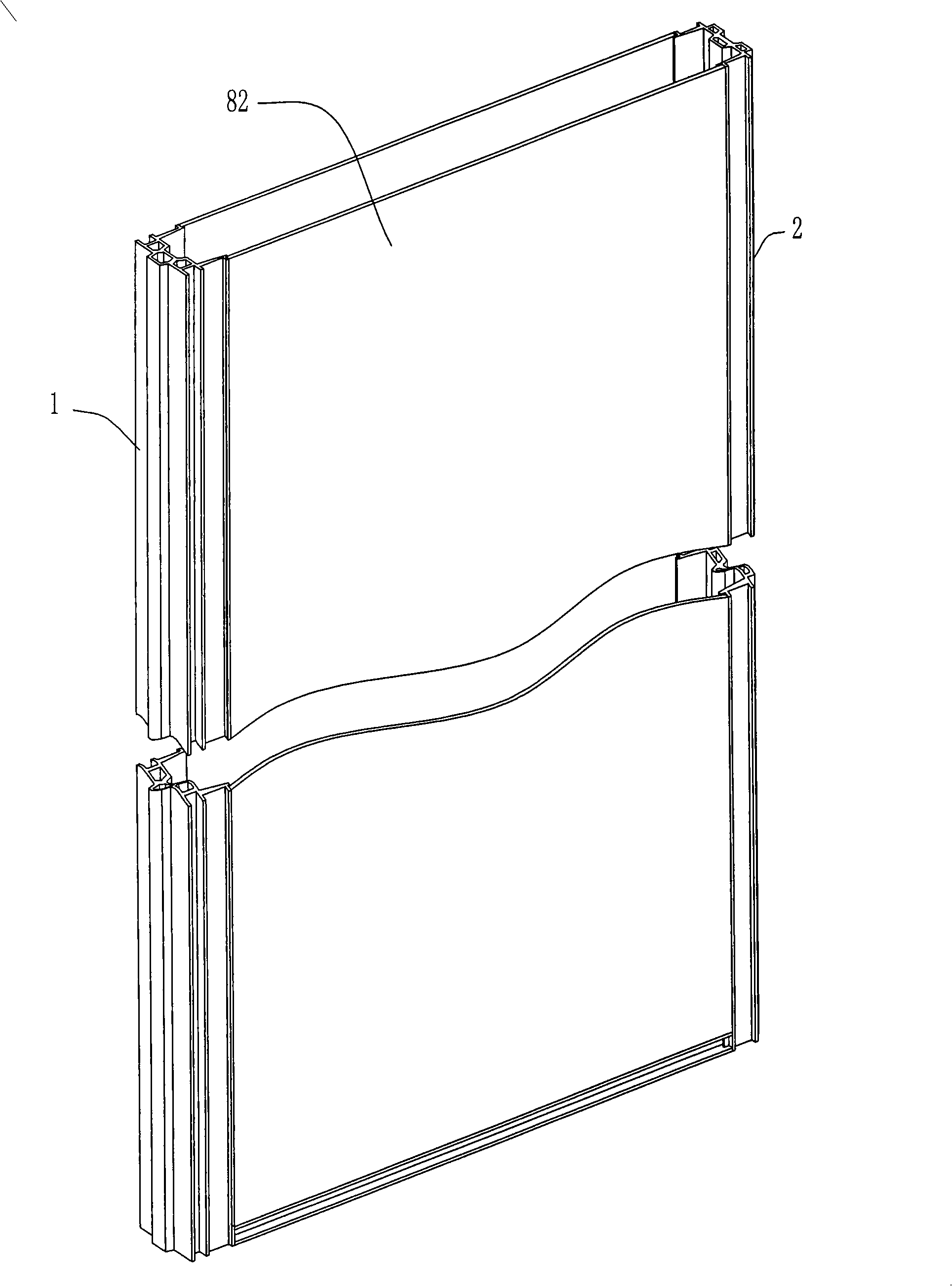

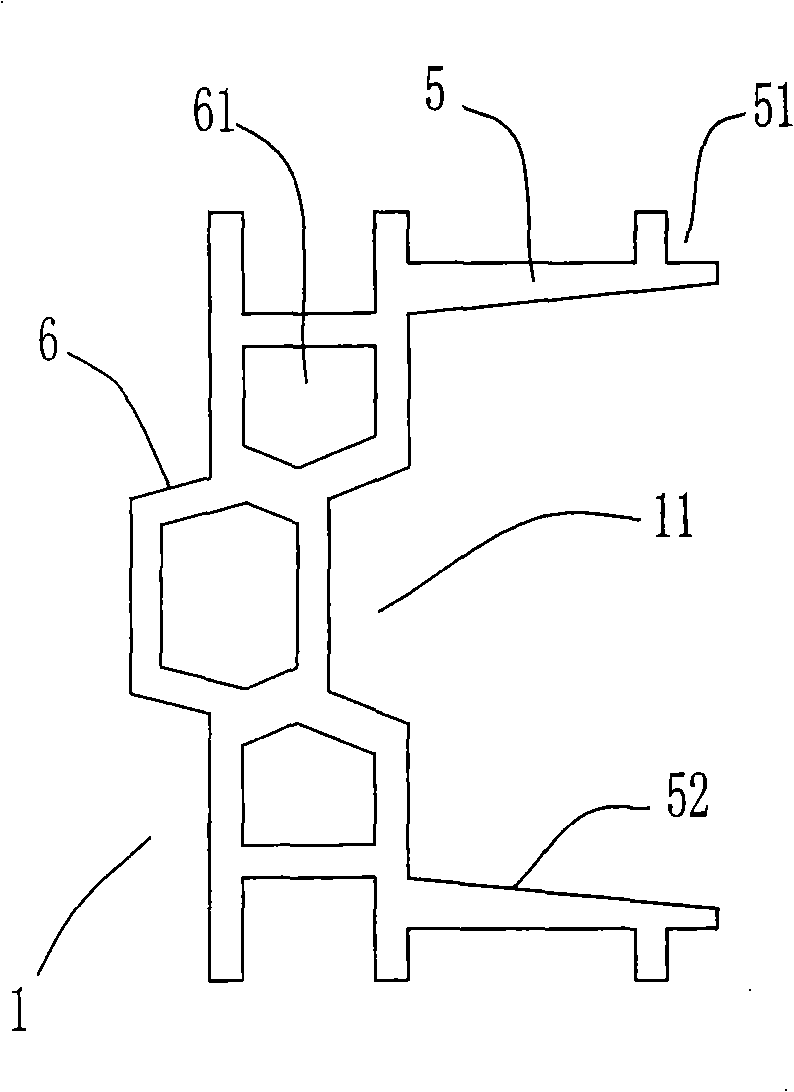

[0017] refer to Figure 1 to Figure 7 , a mold for manufacturing light-weight wall panels, including a frame 4 composed of left and right vertical plates 1, 2 and a bottom plate 3, the inner sides of the left and right vertical plates 1, 2 are respectively provided with corresponding grooves 11 and protrusions 21, said The left and right vertical plates 1 and 2 are respectively provided with U-shaped sides 5 with opposite openings, and the outer edge of the opening of the U-shaped sides 5 is provided with a card slot 51 .

[0018] When the mold of the present invention manufactures lightweight wallboards, the left and right vertical boards 1, 2 are combined with the bottom plate 3 to form a frame 4, and the panels 82 of the wallboards to be processed are installed on the front and rear sides of the frame 4, and the edges of the panels 82 are inserted into the slots 51 to form a storage cavity; molds of the same type can be used to superimpose each other during production, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com