Crankcase ventilation apparatus of V-type engine

A crankcase ventilation and engine technology, applied in crankcase ventilation, engine components, machines/engines, etc., can solve the problems of complex structure, uneven pressure, blue smoke from burning oil, etc., to improve safety performance and improve removal effect. , the effect of reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

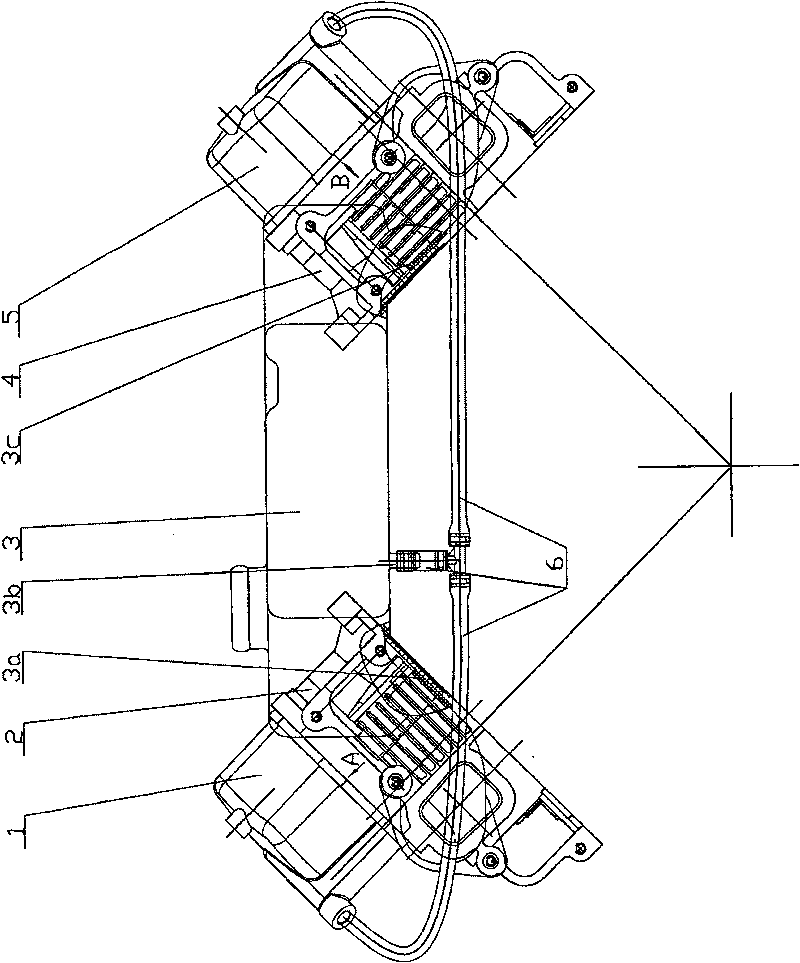

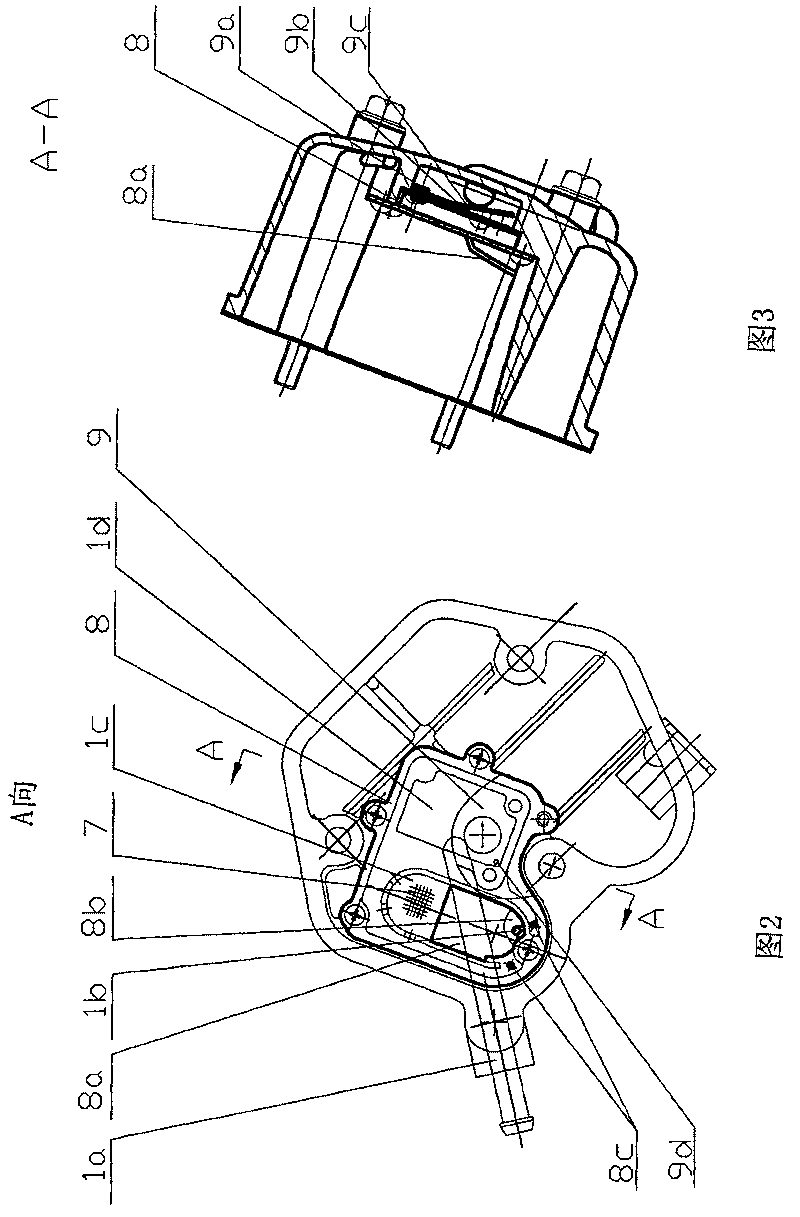

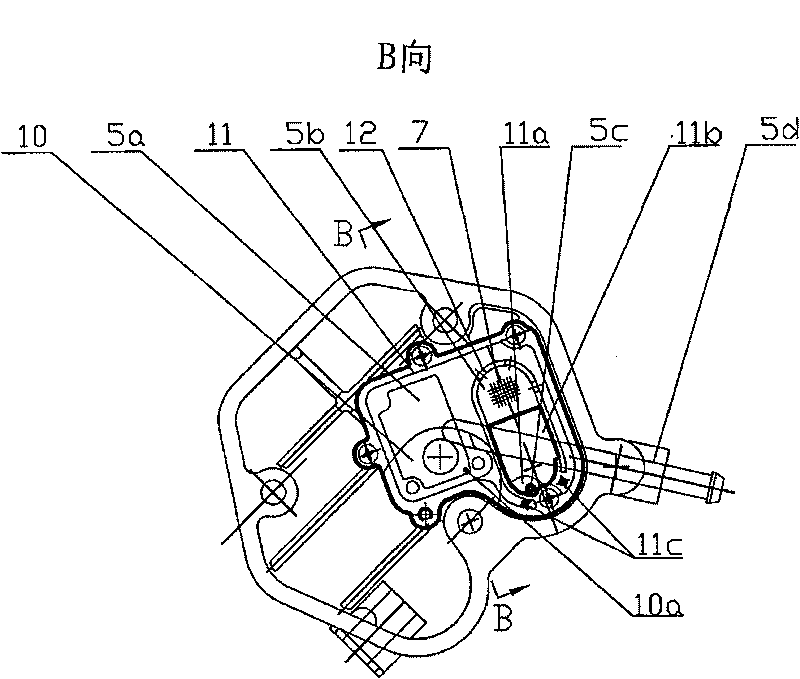

[0017] Such as Figure 1 to Figure 5 As shown, it includes: left and right cylinder head covers 1, 5 (pipeline channels 1a, 5d, ejector rods 1b, 5c, oil-gas separation chambers 1c, 5b, control switch chambers 1d, 5a), left and right cylinder heads 2, 4. Regulator box part 3 (bottom joint 3b, intake connection pipe 3a, 3c), pipeline system 6, filter screen 7, oil baffle 8, 11 (oil baffle support 8a, 11b, oil baffle oil gas Inlets 8b, 11a, oil baffle oil return holes 8c, 11c), check valve components 9, 10 (breather spring 9b, spring plate 9c, cover plate 9a, oil return holes 9d, 10a), etc.

[0018] The present invention mainly adopts to install the intake pressure stabilizing box part 3 on the air intake side of the left and right cylinder heads 2 and 4 arranged in a V shape, and install the left and right cylinder head covers on the left and right cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com