Rapid heating type liquid heating pipe

A heating tube, rapid heating technology, applied in fluid heaters, water heaters, lighting and heating equipment, etc., can solve the problems of the direct heat transfer gap between the heating tube and the water tube, harmful to human health, and easy to deteriorate water quality. Achieve the effect of reducing heat transfer loss, saving energy, and sanitation of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

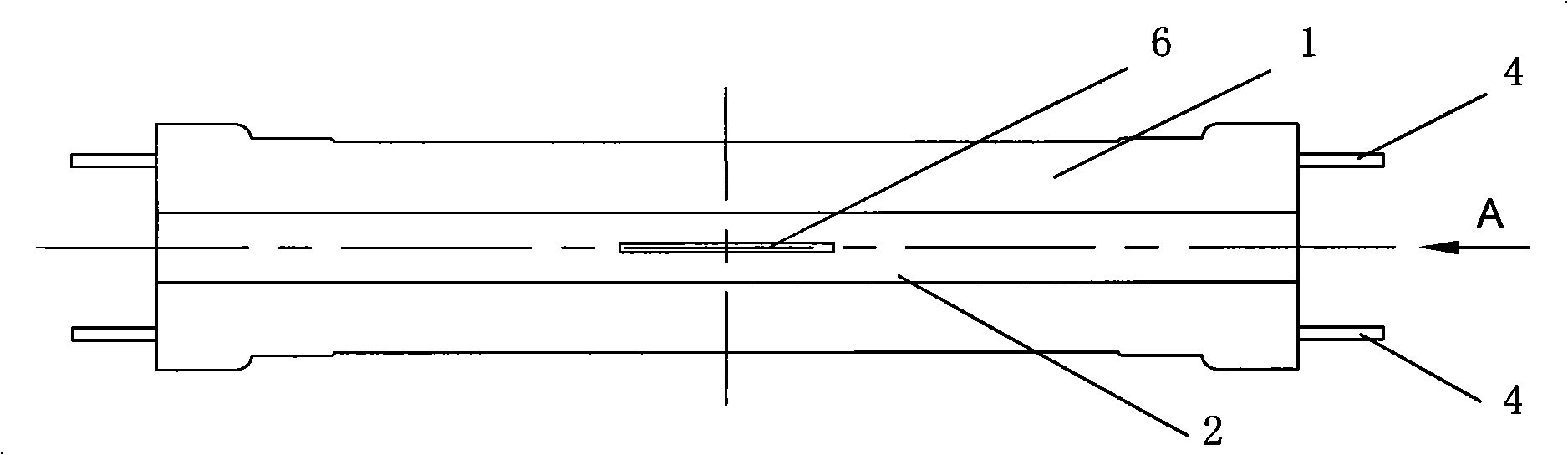

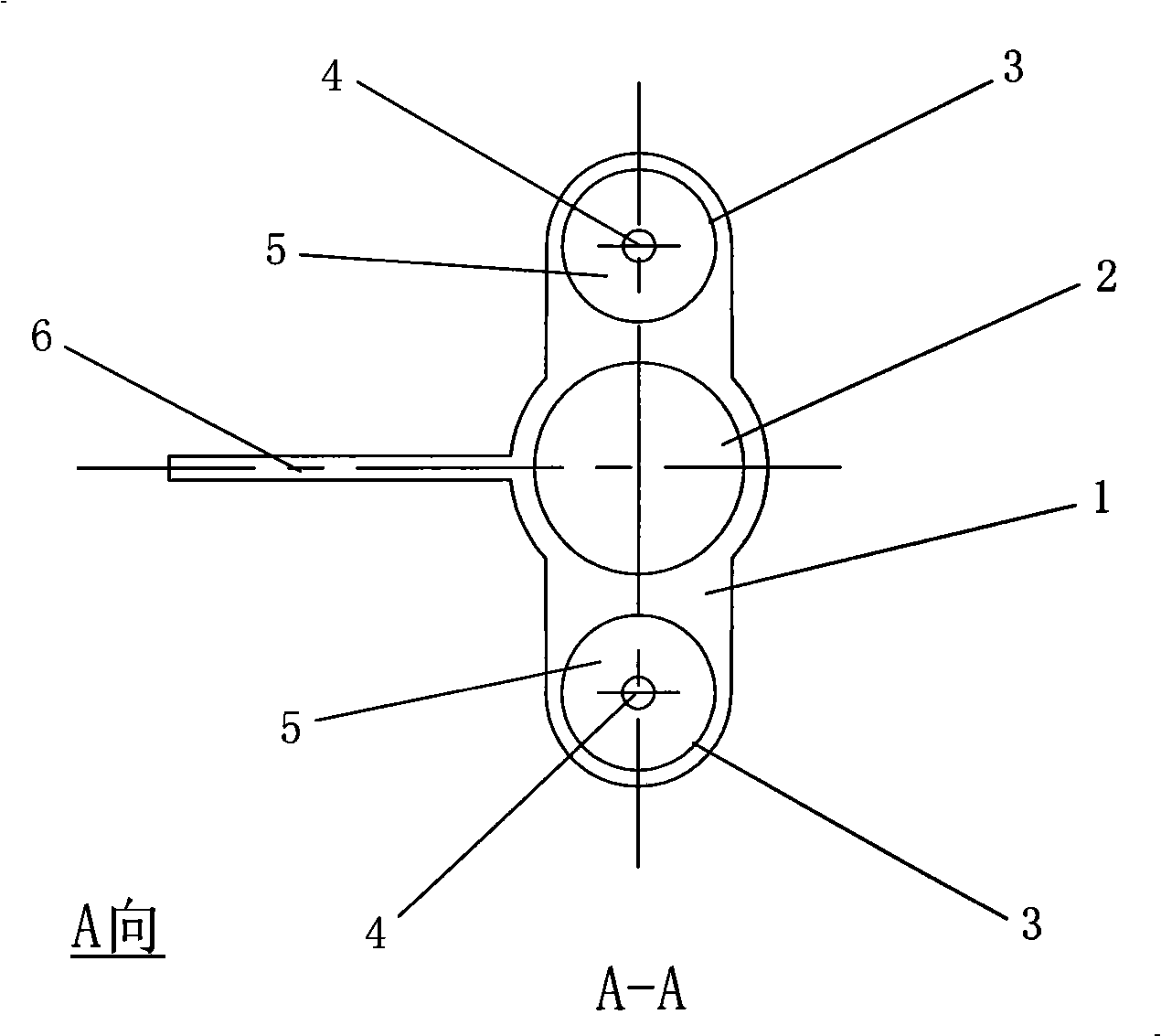

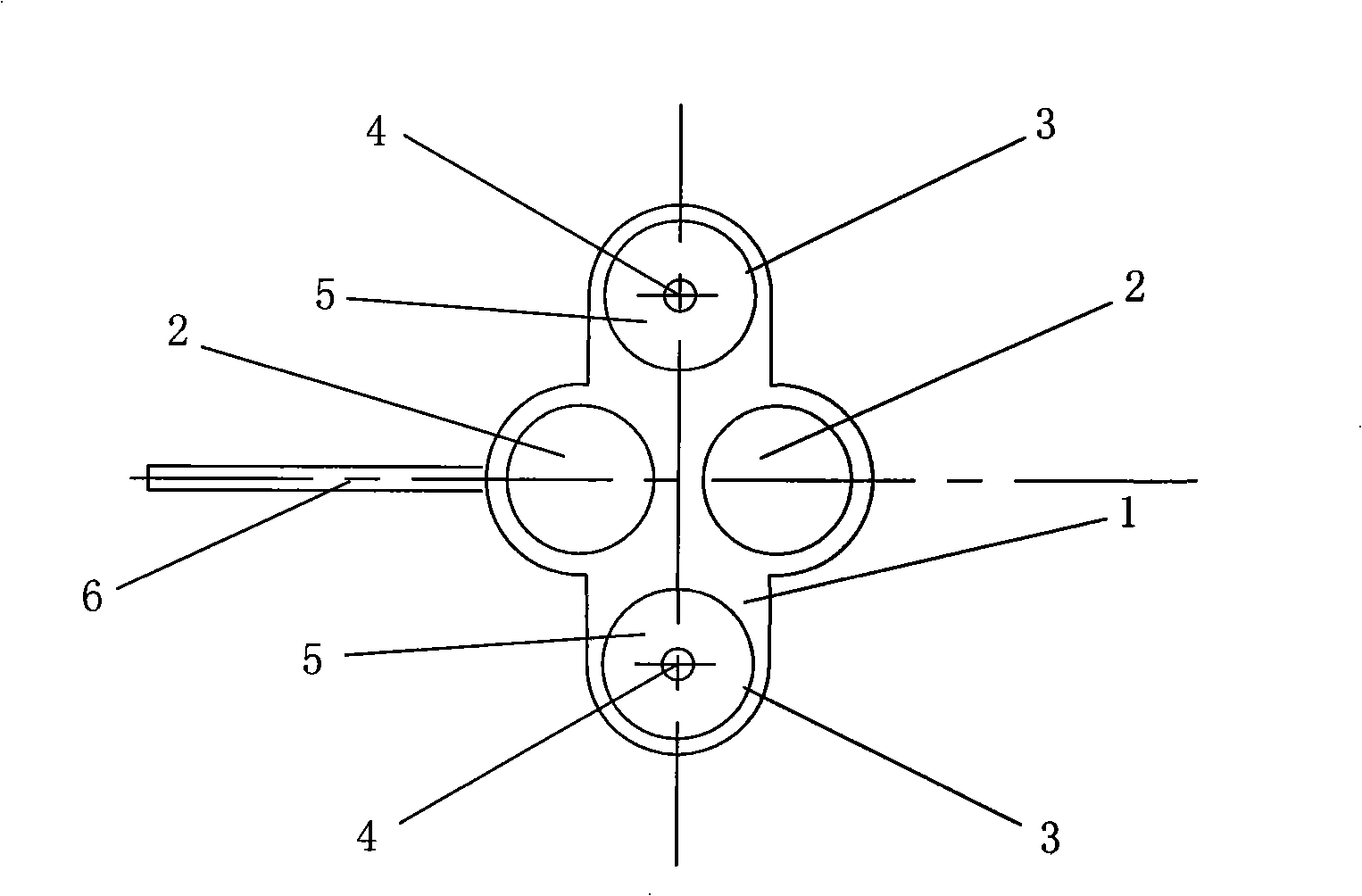

[0026] Such as figure 1 , figure 2 Shown is the integrally designed quick-heating type liquid heating tube adopted by the present invention. The heating pipe has a metal pipe body 1 made of metal with good thermal conductivity. The metal pipe body 1 is provided with a water flow channel 2 that runs through the entire pipe body along the axial direction of the pipe body. Water flows into the water flow channel 2 through one end, and flows out of the water flow channel 2 through the other end, and is sent to a destination requiring hot water. The metal pipe body is also provided with at least one heating wire installation hole 3 passing through the whole pipe body, two in this example, symmetrically arranged on both sides of the water flow channel. The heating wire and the lead-out electrode 4 are fixed in the center of the heating wire installation hole, and the heat-conducting and high-temperature-resistant insulator 5 is filled in the heating wire installation hole to wrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com