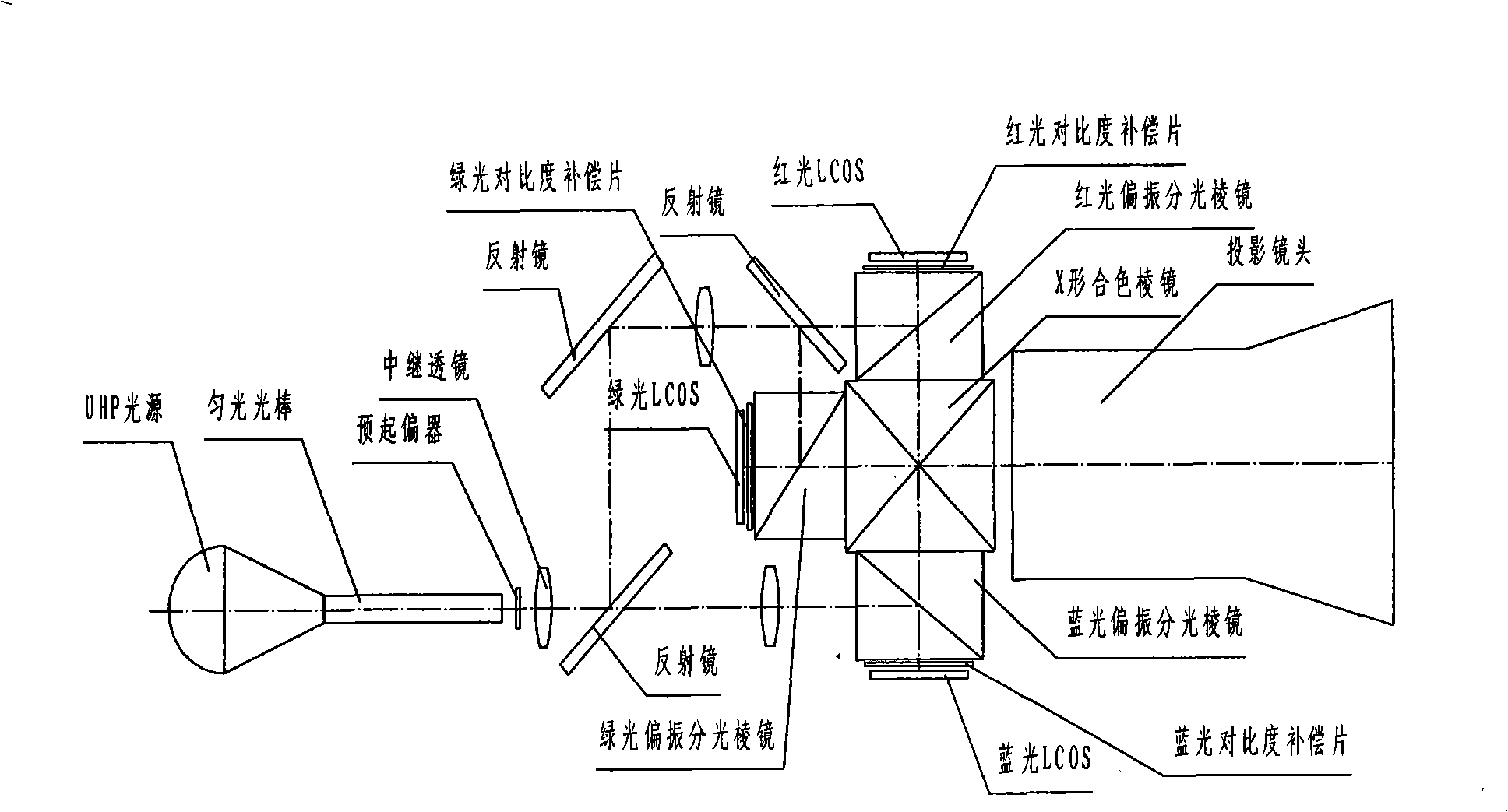

Three-sheet type LCOS projection machine optical engine of three-color LED illumination

An LED lighting and optical engine technology, applied in optics, optical components, instruments, etc., can solve the problems of poor reliability and stability, narrow color gamut of displayed images, complex system heat dissipation, etc., and achieve stable and reliable work, simple heat dissipation, and system simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

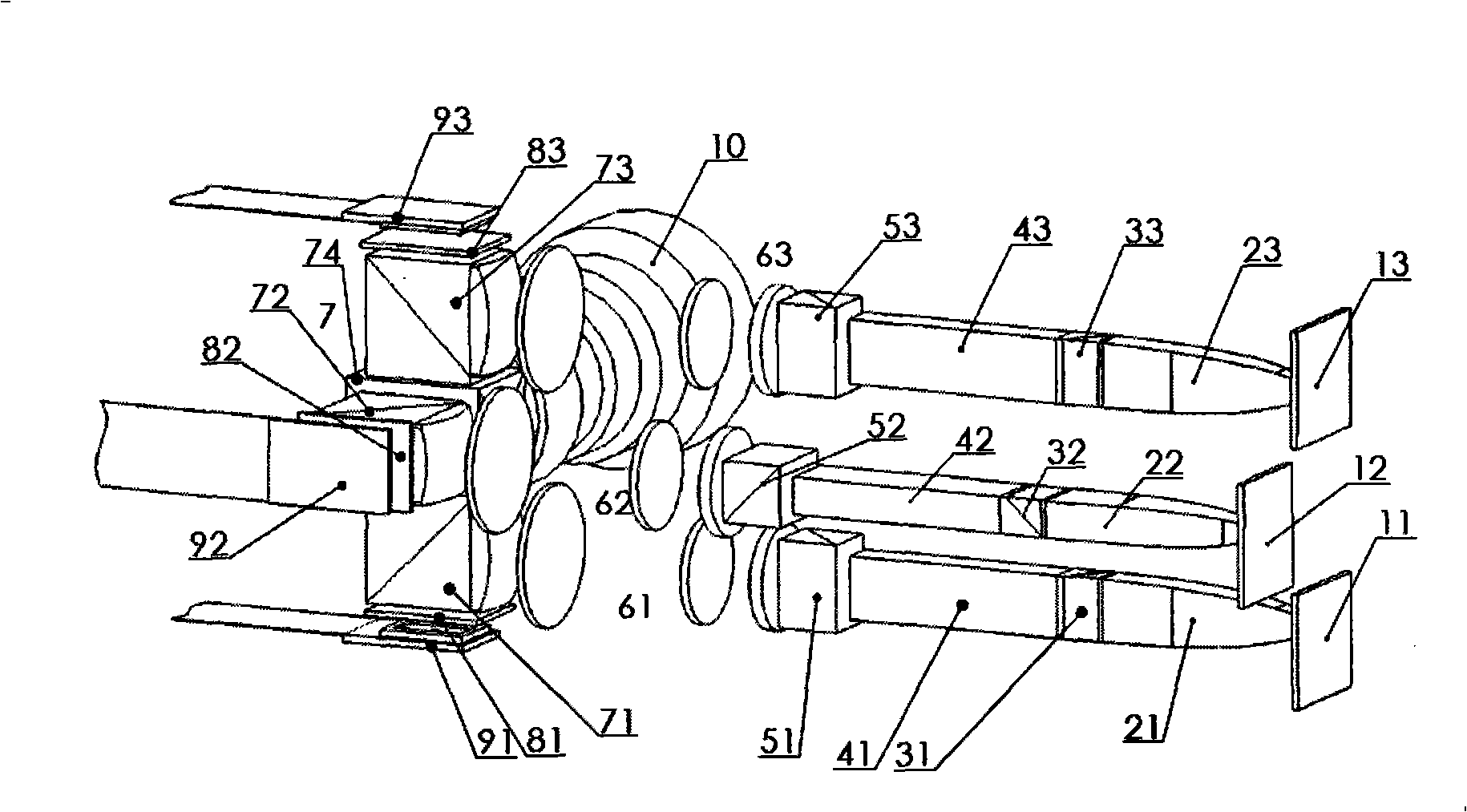

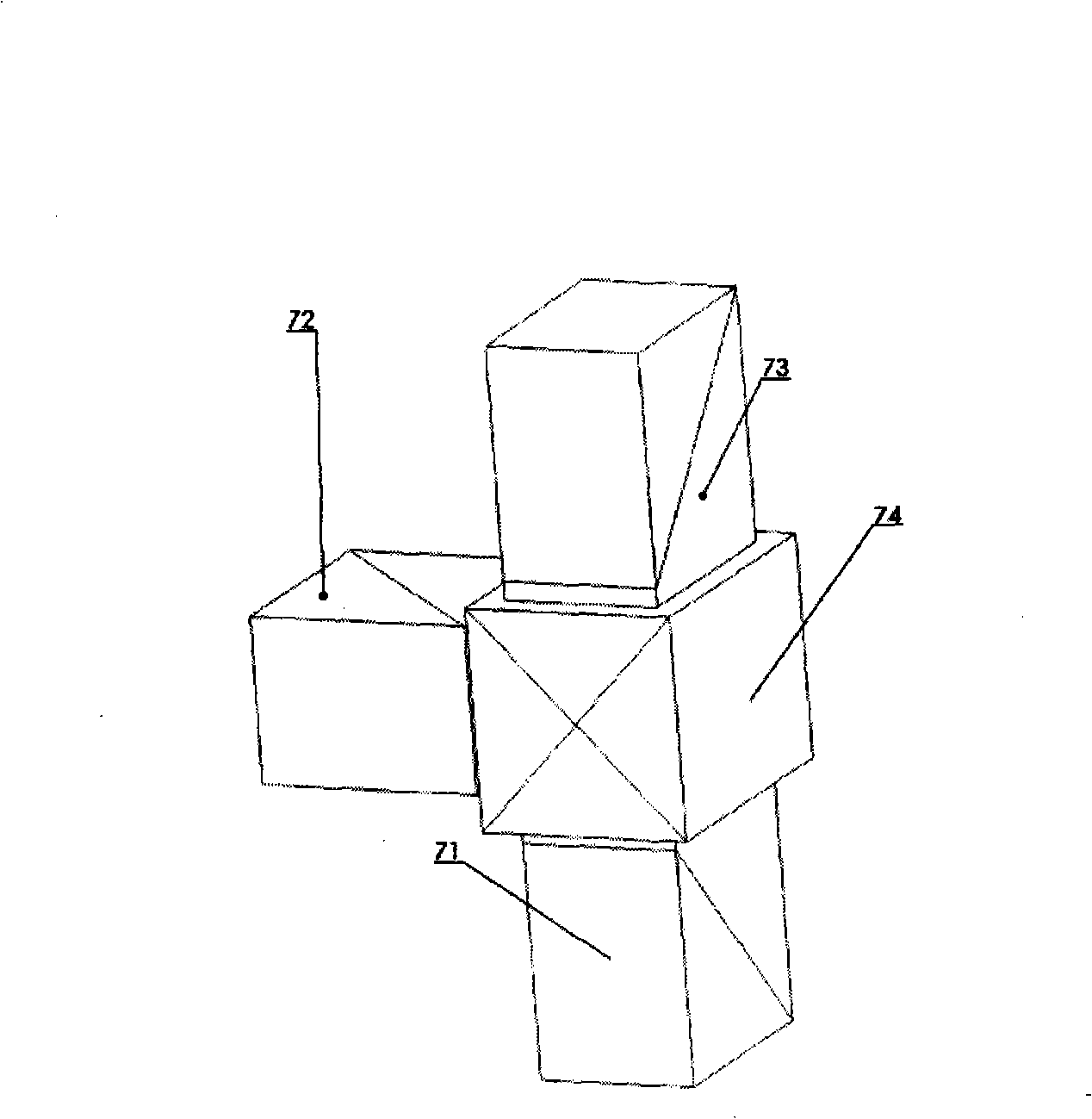

[0019] A three-chip LCOS projector optical engine illuminated by three-color LEDs, including a red light polarization beamsplitter prism 71, a green light polarization beamsplitter prism 72, a blue light polarization beamsplitter prism 73, an X-shaped color combining prism 74, and a red light contrast compensation film 81 , green light contrast compensation film 82, blue light contrast compensation film 83, red light LCOS 91, green light LCOS 92, blue light LCOS 93, projection lens 10, red light polarization beam splitter prism 71, green light polarization beam splitter prism 72, blue light polarization beam splitter prism 73 and X-shaped color combining prism 74 are optically coupled to form a traditional color combining component 7, red light contrast compensation film 81, green light contrast compensation film 82, blue light contrast compensation film 83, red light LCOS 91, green light LCOS 92, blue light LCOS 93. The projection lens 10 is optically coupled with the color co...

Embodiment 2

[0021] Except for the following differences, the remaining parts are identical to Example 1. The feature of this embodiment is that the structures of the red, green and blue lighting systems are completely the same.

Embodiment 3

[0023] Except for the following differences, the remaining parts are identical to Example 1 and Example 2. The feature of this embodiment is that the red, green and blue lighting systems are arranged on the same side of the LCOS image projection optical system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com