Anti-sloshing device in moon pool

A moon pool and ship bow technology, which is applied in the field of anti-sloshing devices in the moon pool, can solve the problems of reduced worker safety and work efficiency, reduced speed, hull damage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

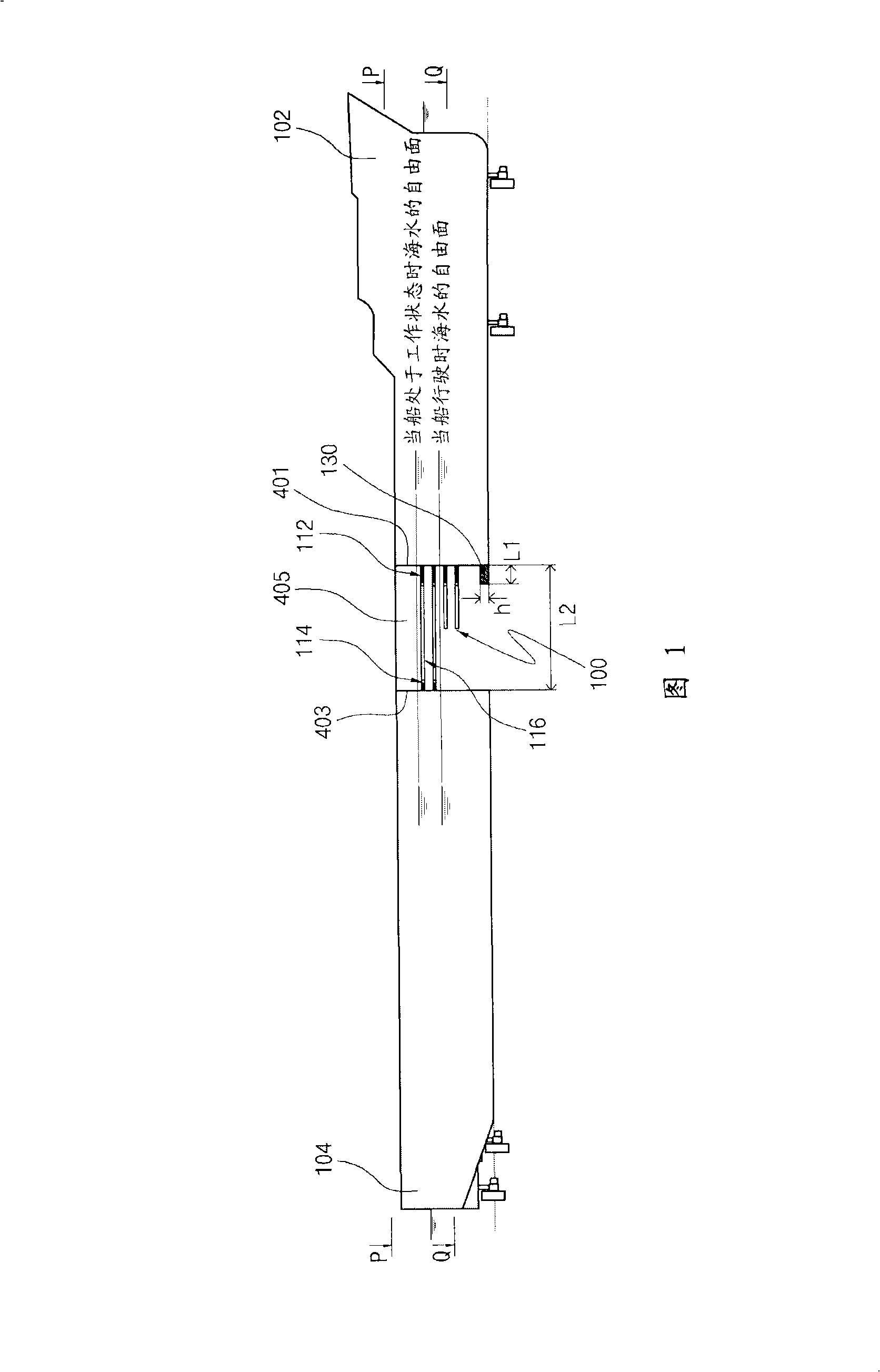

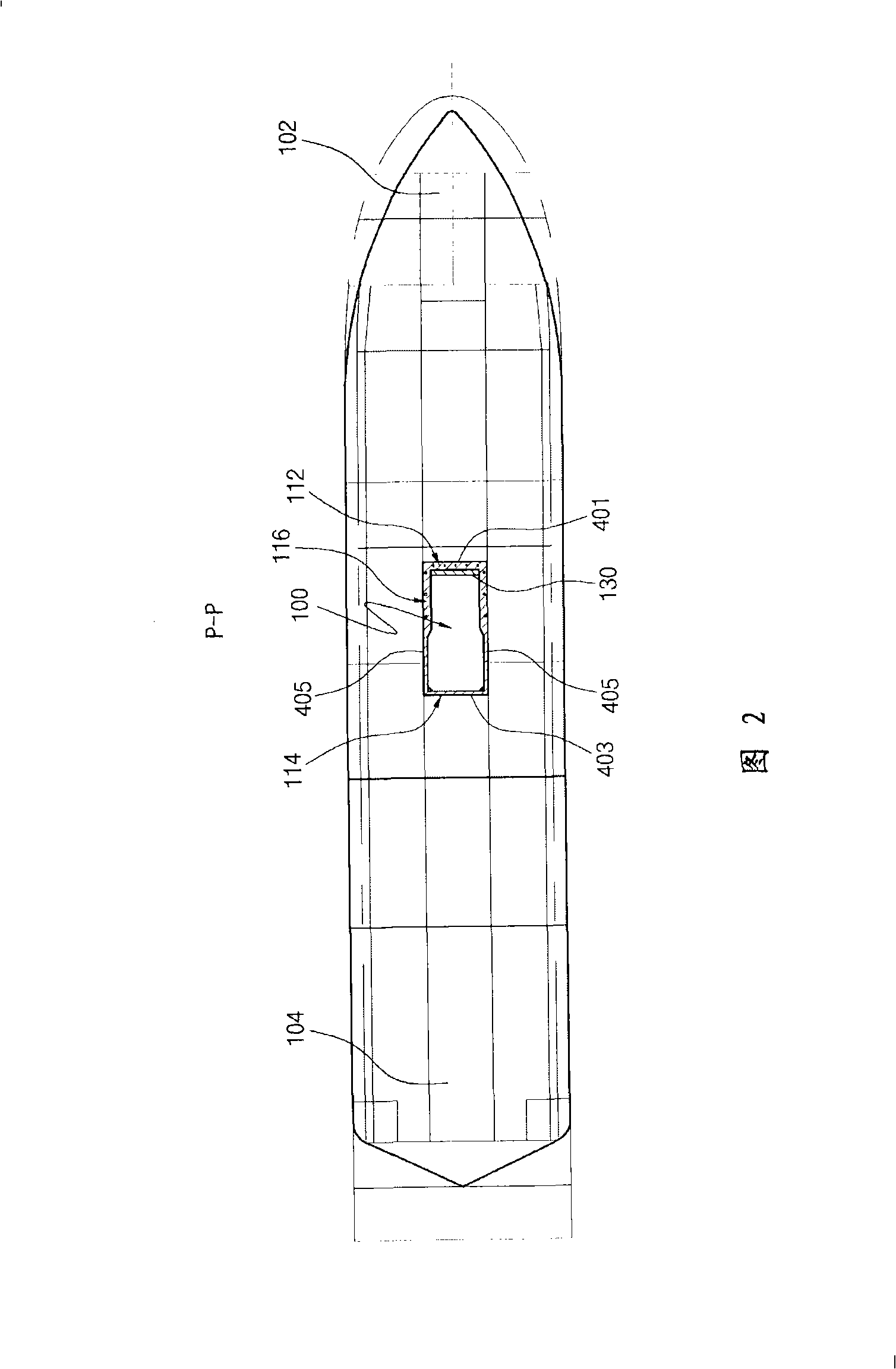

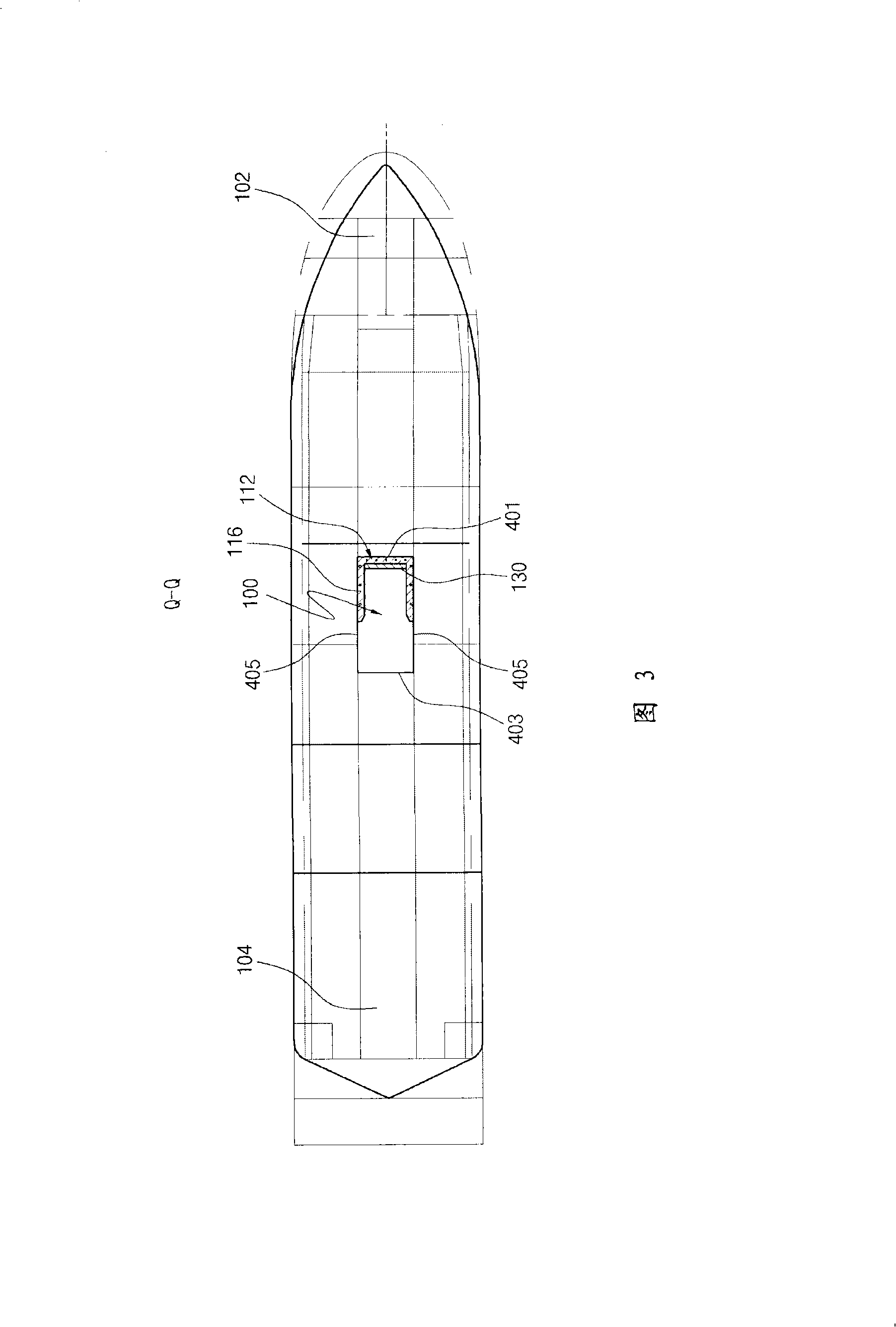

[0040] FIG. 1 is a side sectional view showing a ship having an anti-sloshing moonpool structure according to a first embodiment of the present invention. FIG. 2 is a top sectional view taken along line P-P of FIG. 1 . FIG. 3 is a top sectional view taken along line Q-Q of FIG. 1 . FIG. 4 is a perspective view showing a part of the first embodiment of FIG. 1 .

[0041] As shown in FIG. 1 , according to the position in the ship, the ship having the anti-sloshing moonpool structure according to the present invention is divided into: a bow part 102 forming the front of the ship; a stern part 104 forming the rear part of the ship; a moon pool 100 , formed between the bow portion 102 and the stern portion 104 .

[0042] The moon pool 100 is formed vertically through the ship from the top of the ship to the bottom of the ship, and the moon pool 100 is used as a passage through which drilling machinery and drilling pipes reach the seabed.

[0043] The anti-sloshing moonpool struct...

no. 2 example

[0071] The anti-sloshing moonpool structure according to the second embodiment of the present invention is configured such that the protruding length of the moonpool panels decreases from the top of the ship to the bottom of the ship so that the maximum working area expands toward the bottom of the ship. The technical spirit is the same as or similar to that of the first embodiment. Therefore, in Figure 1 to Figure 7 The same reference numerals are used throughout the different drawings to indicate the same or similar parts. Also, explanations of these components will be omitted.

[0072] Figure 5 and Image 6 As shown, several pool panels 212, 214 and 216 are vertically bonded to the bow side wall 401 and the stern side wall 403 respectively from the top of the ship to the bottom of the ship at positions spaced apart from each other at predetermined intervals along the height direction of the ship. and on the opposite side walls 405 .

[0073] refer to Image 6 , the term...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com