Method for treating stainless steel smelting slag

A treatment method, stainless steel technology, applied in the field of stainless steel smelting slag treatment, can solve problems such as explosion accidents and difficult slag cooling effects, and achieve the effects of preventing explosion accidents, optimal cooling effect, and guaranteed cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

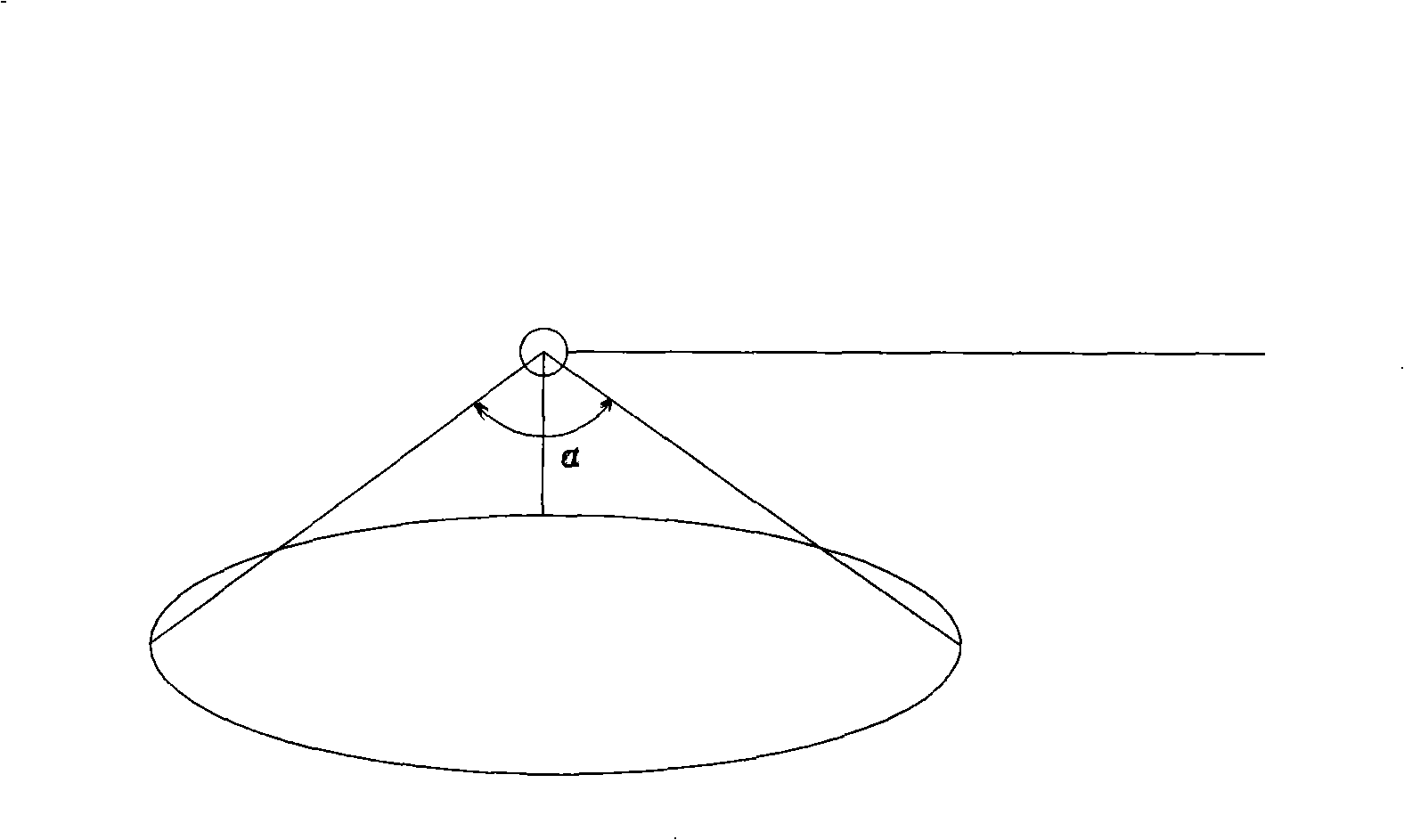

Image

Examples

Embodiment 1

[0013] Use 17M 3 The slag tank is filled with hot stainless steel slag, lifted to the open-air cooling field, and left to cool naturally in the air. Generally, after 16-20 hours of air cooling, the temperature of the tank wall is intermittently measured. When the highest temperature of the tank wall is 170°C or 160°C When the temperature is even lower, use a spray gun to spray water directly on the surface of the steel slag in the slag tank continuously. After natural cooling, the temperature of the slag is greatly reduced, that is, there is no molten slag, and the cooling can be increased. Water flow rate to speed up the cooling of hot slag, so water can be continuously added until 100mm of water accumulates above the steel slag in the slag tank, and the temperature of the tank wall is measured after standing still. If the highest temperature of the tank wall is higher than 90°C, the water above the steel slag evaporates quickly Make water replenishment before, until 100mm of...

Embodiment 2

[0016] use 6M 3 The slag tank is filled with hot stainless steel slag, lifted to the open-air cooling field, and left to cool naturally in the air. Generally, after 10-14 hours of air cooling, the temperature of the tank wall is intermittently measured. When the highest temperature of the tank wall is 170°C or 160°C When the temperature is even lower, use a spray gun to spray water directly on the surface of the steel slag in the slag tank continuously. After natural cooling, the temperature of the slag is greatly reduced, that is, there is no molten slag, and the cooling can be increased. Water flow rate to speed up the cooling of hot slag, so water can be continuously added until 100mm of water accumulates above the steel slag in the slag tank, and the temperature of the tank wall is measured after standing still. If the highest temperature of the tank wall is higher than 90°C, the water above the steel slag evaporates quickly Make up water before, until 100mm of accumulated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com