Urea formaldehyde alkyd woodenware top coat and method for manufacturing same

A manufacturing method, alkyd technology, applied in the field of coatings, can solve the problems of resource waste of petroleum products, slow drying speed, poor durability of paint films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

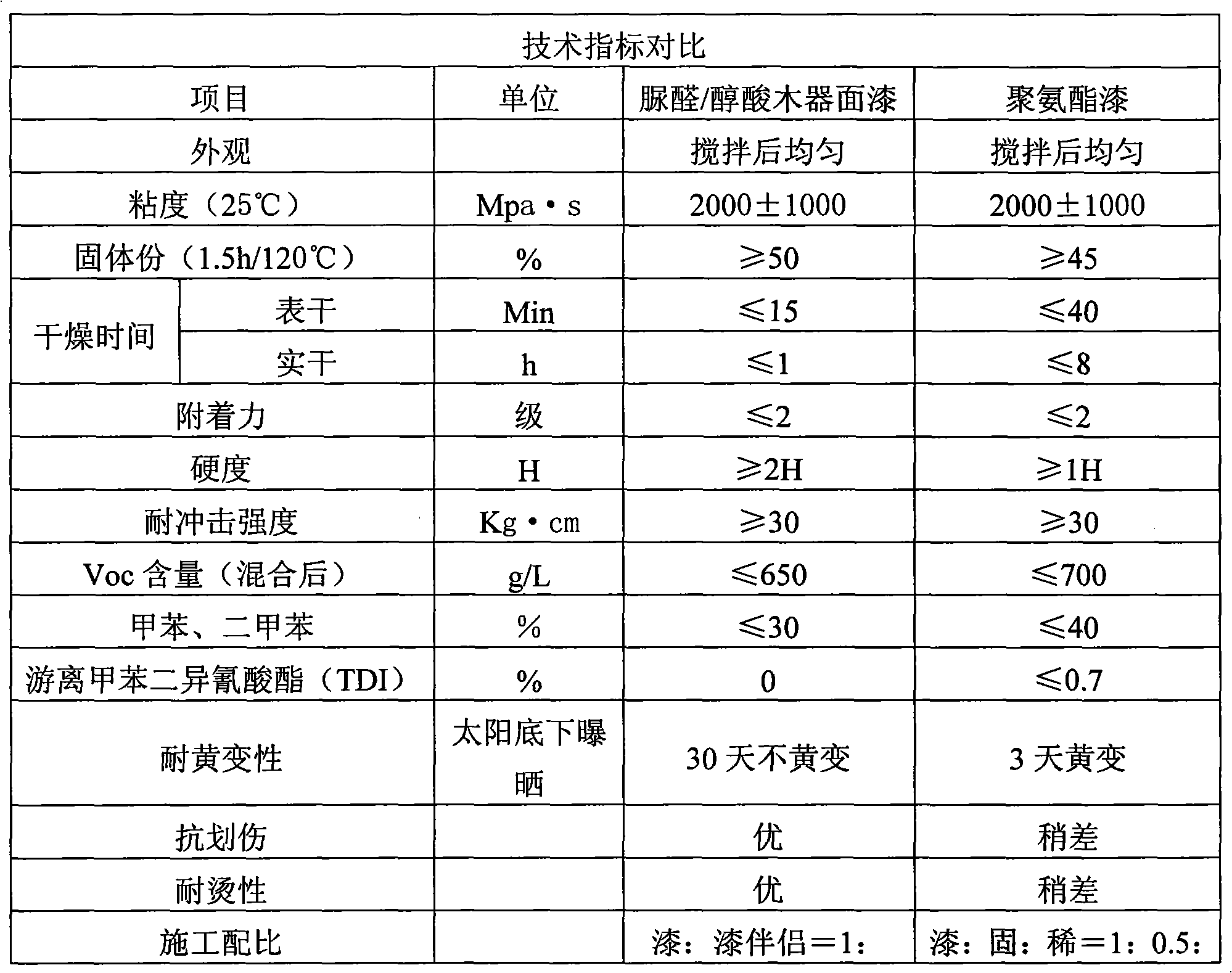

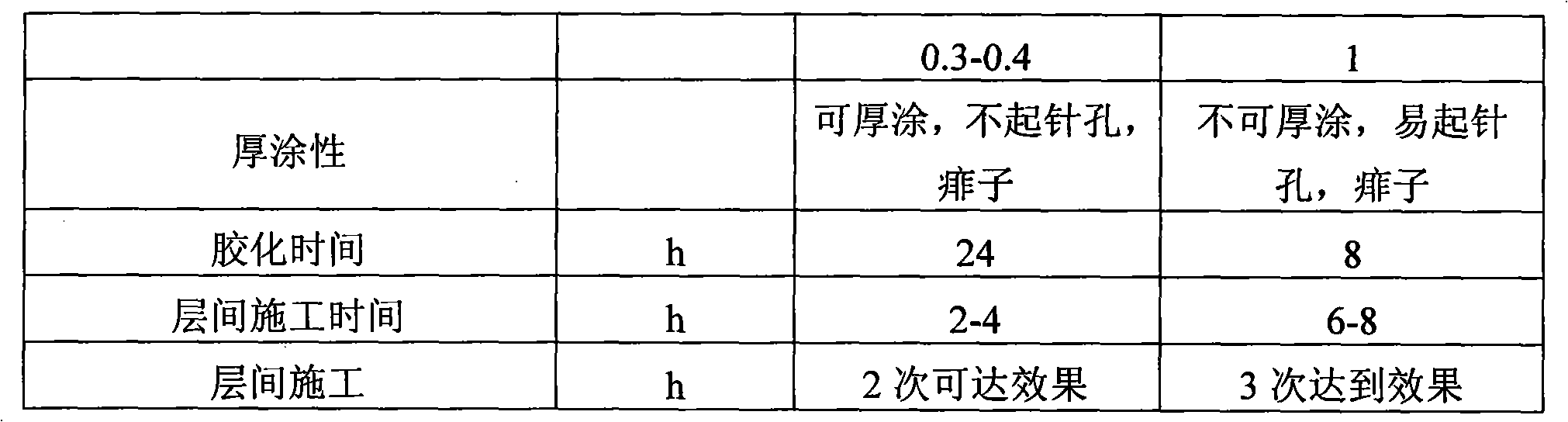

Image

Examples

Embodiment 1

[0026] Embodiment 1, a kind of urea-formaldehyde / alkyd wood topcoat, comprises semi-mat clear finish paint and lacquer companion, and the construction weight ratio of semi-mat clear finish paint and paint companion is 1: 0.3, wherein:

[0027] (1) The weight ratio of each component of the semi-matte finish paint is:

[0028] Soybean oil or soybean oil modified medium or short oil alkyd resin with a solid content of 70±2% 34%

[0029] (Sanki Chemical Company, 3370D)

[0030] Butanol etherified urea-formaldehyde resin has a solid content of 60±2% 58%

[0031] (Sanki Chemical Company, 5260)

[0032] Polycarboxylate dispersant (Byk104) 0.2%

[0033] Fumed silica matting agent particle size 1.5-3um (ED30, Gray period) 2%

[0034] Polyethylene wax anti-settling agent (201P, Shanghai Deqian) 1.5%

[0035] Polyether silicone leveling agent (6510, Shanghai Haichuan) 0.25%

[0036] Aralkyl silicone leveling agent (efka3239, Efcona) 0.15%

[0037] E1 defoamer (Shanghai Haichuan) 0...

Embodiment 2

[0047] Embodiment 2, a kind of urea-formaldehyde / alkyd wood finish paint, comprises semi-mat clear finish paint and lacquer companion, and the construction weight ratio of semi-mat clear finish paint and paint companion is 1: 0.4, wherein:

[0048] (1) The weight ratio of each component of the semi-matte finish paint is:

[0049] Soybean oil or soybean oil modified medium or short oil alkyd resin with a solid content of 70±2% 31.5%

[0050] (Sanki Chemical Company, 3370D)

[0051] Butanol etherified urea-formaldehyde resin has a solid content of 60±2% 60.5%

[0052] (Sanki Chemical Company, 5260)

[0053] Polycarboxylate dispersant (Byk104) 0.15%

[0054] Fumed silica matting agent particle size 1.5-3um (ED30, Gray period) 2%

[0055] Polyethylene wax anti-settling agent (201P, Shanghai Deqian) 1.5%

[0056] Polyether silicone leveling agent (6510, Shanghai Haichuan) 0.2%

[0057]Aralkyl silicone leveling agent (efka3239, Efcona) 0.03%

[0058] E1 defoamer (Shanghai Hai...

Embodiment 3

[0066] Embodiment 3, a kind of urea-formaldehyde / alkyd wood finish paint, comprises semi-mat clear finish paint and lacquer companion, and the construction weight ratio of semi-mat clear finish paint and paint companion is 1: 0.35, wherein:

[0067] (1) The weight ratio of each component of the semi-matte finish paint is:

[0068] Soybean oil or soybean oil modified medium or short oil alkyd resin with a solid content of 70±2% 36.5%

[0069] (Sanki Chemical Company, 3370D)

[0070] Butanol etherified urea-formaldehyde resin has a solid content of 60±2% 59.7%

[0071] (Sanki Chemical Company, 5260)

[0072] Fumed silica matting agent particle size 1.5-3um (ED30, Gray period) 1.5%

[0073] Polyethylene wax anti-settling agent (201P, Shanghai Deqian) 1%

[0074] Polyether silicone leveling agent (6510, Shanghai Haichuan) 0.1%

[0075] E1 defoamer (Shanghai Haichuan) 0.2%

[0076] n-Butanol 1%

[0077] (2) The weight ratio of each component of Lacquer Mate is:

[0078] p-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com