Plasma chemical vapor deposition process for preventing generation of bag type defects

A technology of chemical vapor deposition and plasma, which is applied in the field of ion chemical vapor deposition, can solve the problems affecting the process production, affecting the appearance, affecting the accuracy of lithographic calibration accuracy and graphics, and achieve the effect of avoiding bag-shaped defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The plasma chemical vapor deposition method of the present invention that can avoid bag-like defects will be further described in detail below.

[0015] The plasma chemical vapor deposition method of the present invention that can avoid the generation of bag-shaped defects is carried out in a plasma chemical vapor deposition equipment, which has a reaction chamber, the same number of wafer deposition tables and correspondingly arranged in the reaction chamber. A microwave generator, wherein the wafer deposition table is used to carry a wafer for chemical vapor deposition, and a heating unit for heating the wafer is arranged on it. In this embodiment, the plasma chemical vapor deposition equipment has two wafer deposition tables and two power generators as an example for illustration.

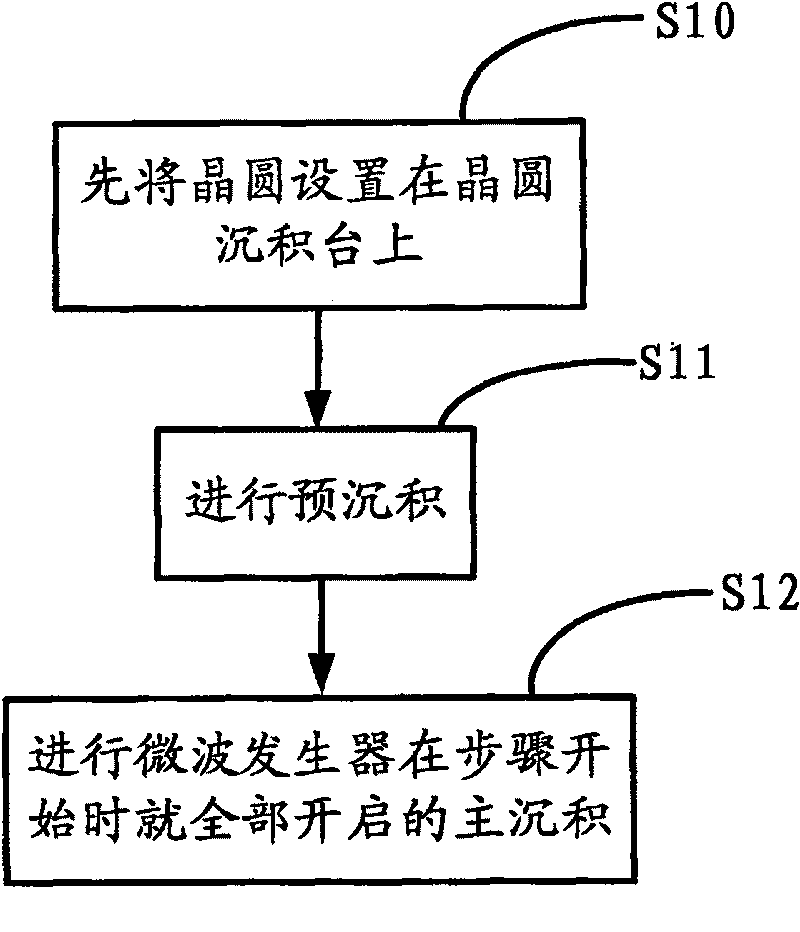

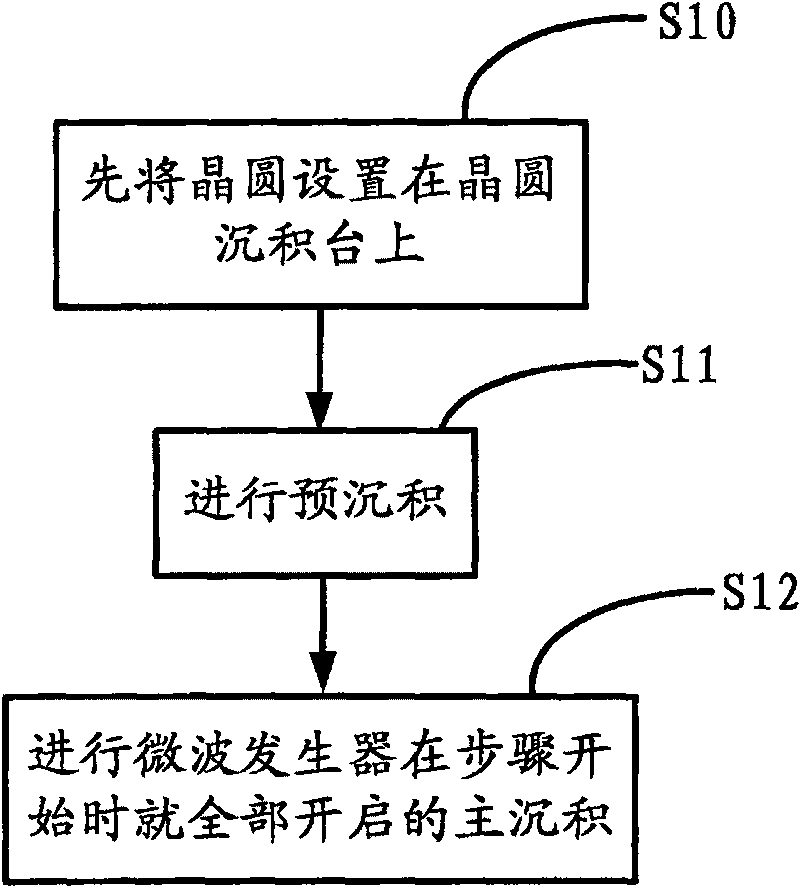

[0016] With plasma chemical vapor deposition equipment at the ready, see figure 1 , the plasma chemical vapor deposition method of the present invention first sets the wafer on the wafer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com