Anti-slip material coating on easily wettable and sliding floor and method of use thereof

A coating material and coating technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems of high cost, inappropriateness, and theft, and achieve the effect of increasing the friction coefficient and improving the adhesion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same reference numerals.

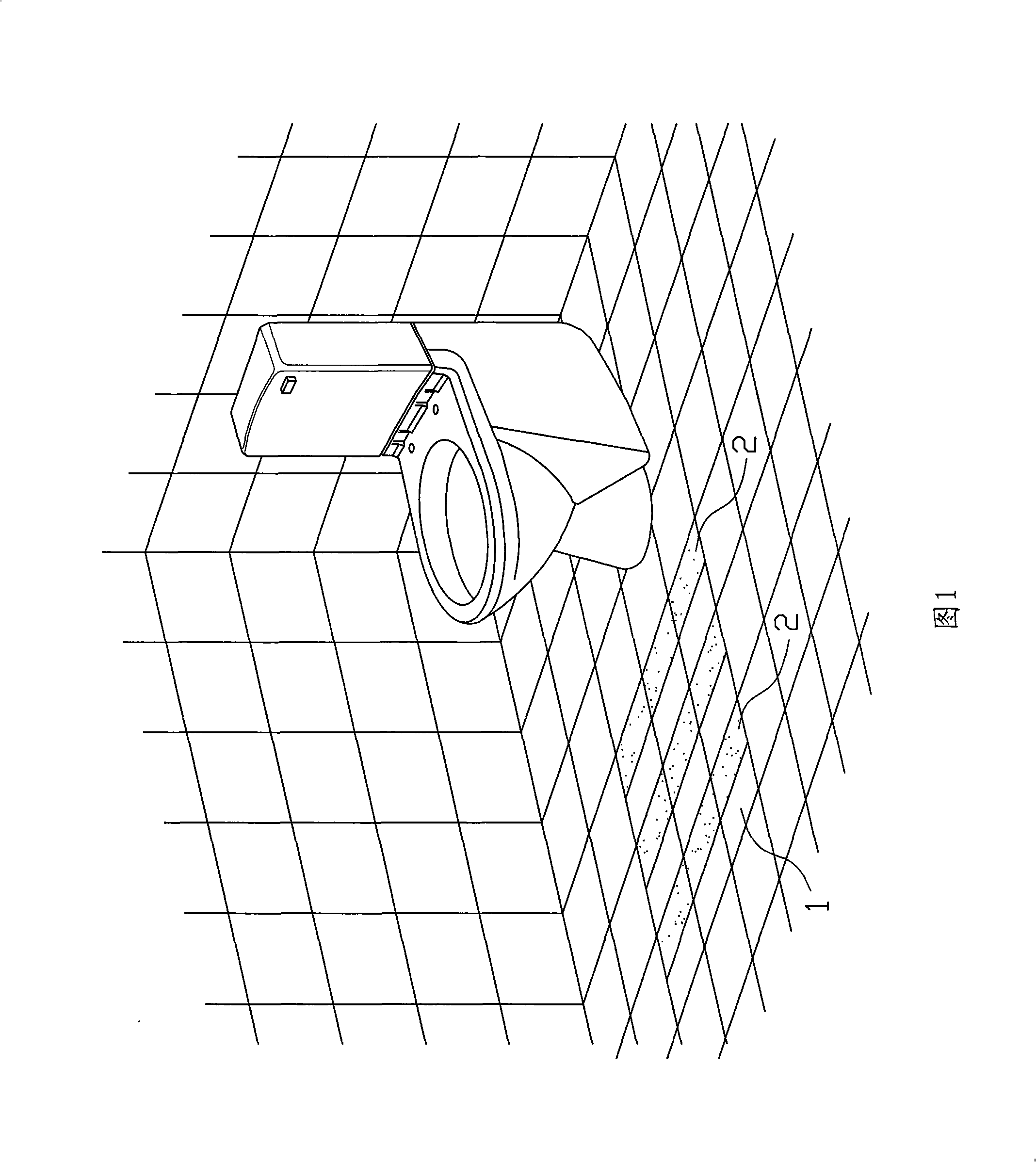

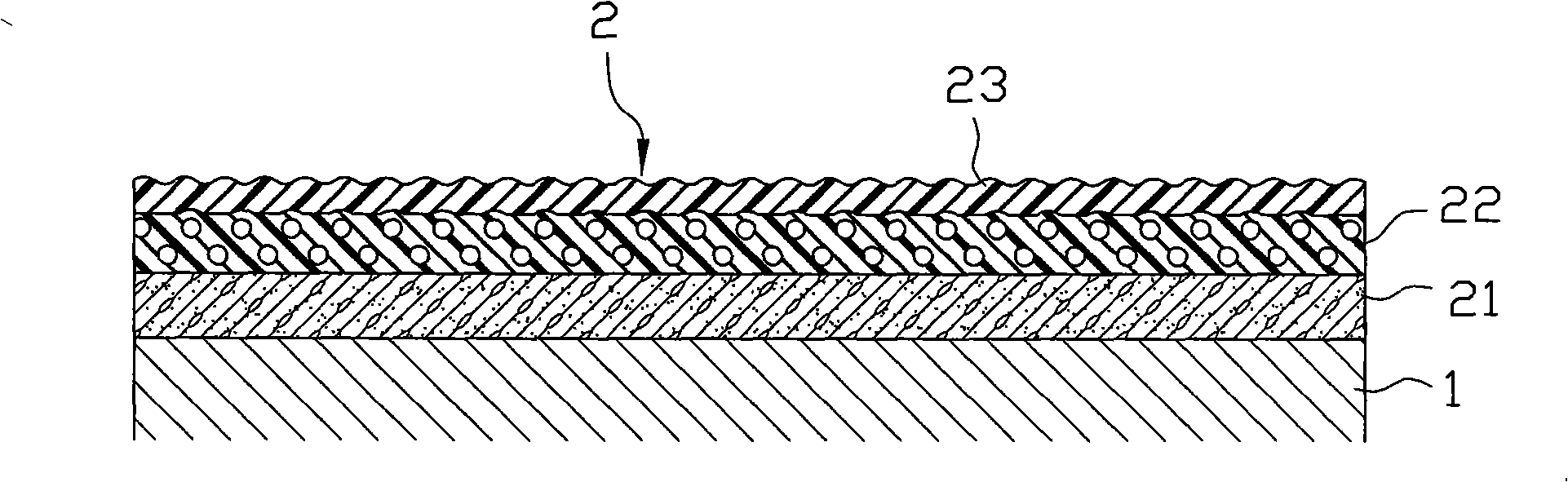

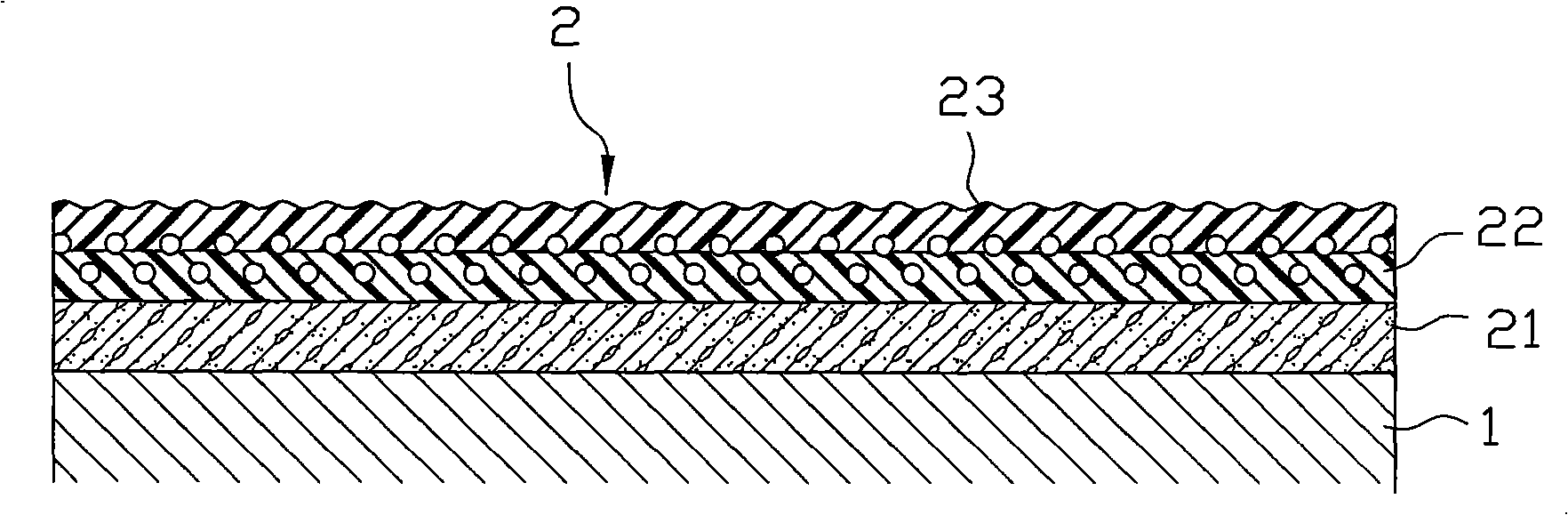

[0025] As shown in Figures 1 and 2, it is the first preferred embodiment of the anti-slip material 2 coated on the slippery and slippery floor of the present invention, which is suitable for covering on the smooth floor 1 of the bathroom, and the anti-slip material 2 includes a A base coating 21 , an anti-slip coating 22 , and a surface coating 23 .

[0026] The base coat 21 is directly coated on the surface of the smooth floor 1, and contains acrylic resin (Acrylic Resin), inorganic aggregate, and cement (Cement), and can be repeated more than two times The coating of the base coat 21. Acrylic resins use acrylates, such as methyl acrylate, ethyl acrylate, butyl acrylate, or octyl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com