Device of engine for continuously changing air valve phase

A phase device, engine technology, applied in engine components, engine control, combustion engine, etc., can solve the problems of complex structure, inconvenient valve clearance adjustment, loud noise, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

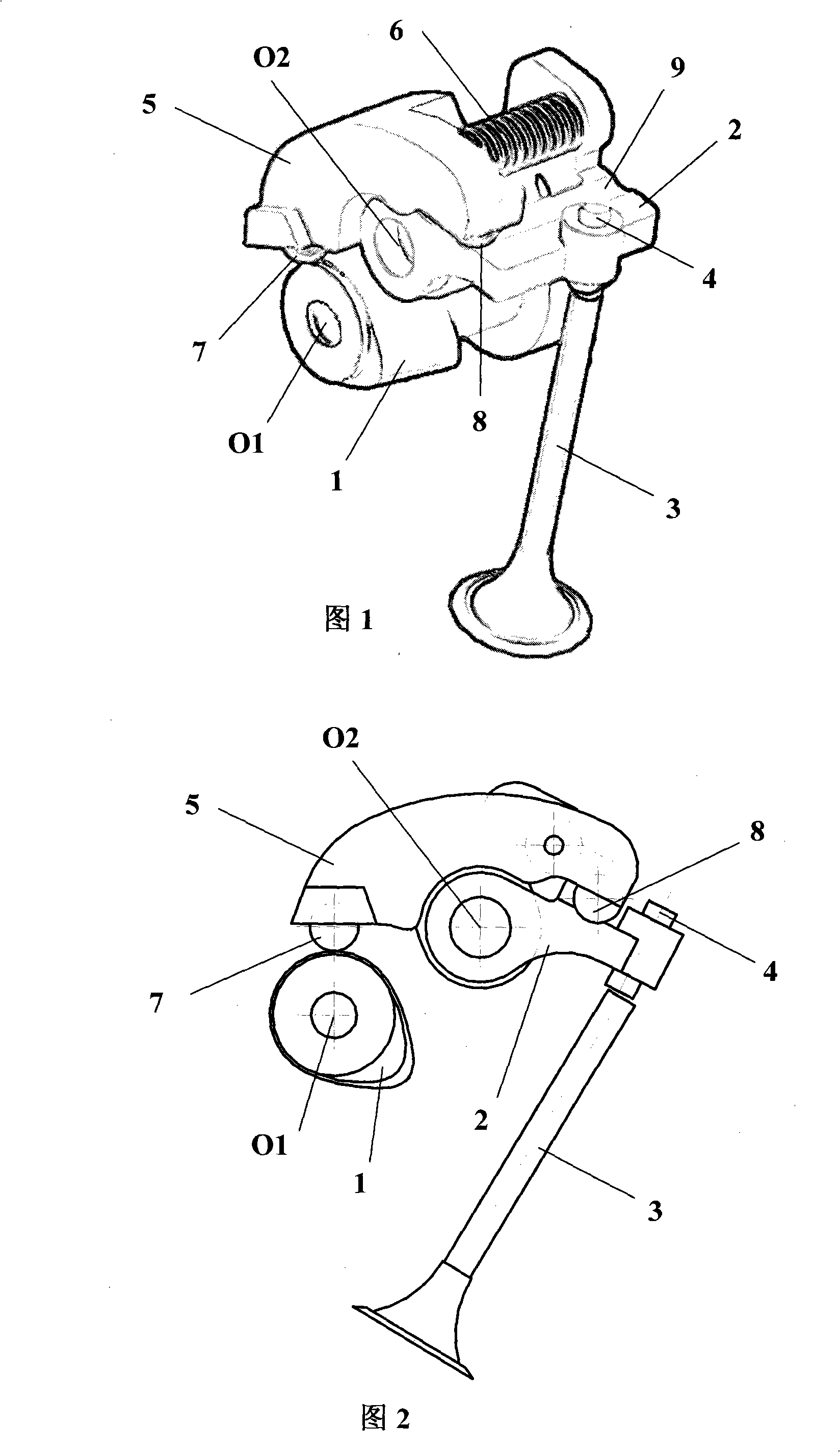

[0008] Fig. 1 and Fig. 2 respectively show a three-dimensional structure schematic diagram and a cross-sectional schematic diagram of an embodiment of a continuously variable valve phase device for an engine according to the present invention. In this embodiment, the device includes a three-dimensional cam 1, a main rocker arm 2, a valve 3 and a valve clearance adjustment screw 4; the three-dimensional cam 1 rotates around its axis O1, and the profile of the cross section of the three-dimensional cam 1 is The axial direction of the camshaft changes continuously and smoothly and corresponds to different working conditions of the engine; the main rocker arm 2 only rotates around its axis O2 without axial movement, and the valve clearance adjustment screw 4 is arranged on the main rocker arm 2; What is different from the previous valve driving mechanism is that in this embodiment, an auxiliary rocker arm 5 is arranged between the three-dimensional cam 1 and the main rocker arm 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com