Ingredient content analytical method for turbine blade salt deposition and scaling

A technology of a steam turbine blade and an analysis method, applied in the field of analysis and testing, can solve problems such as inaccurate detection methods, inability to obtain reliable data, etc., and achieve the effects of avoiding difficult expressions and large errors, complete calculation methods, and overcoming calculation errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

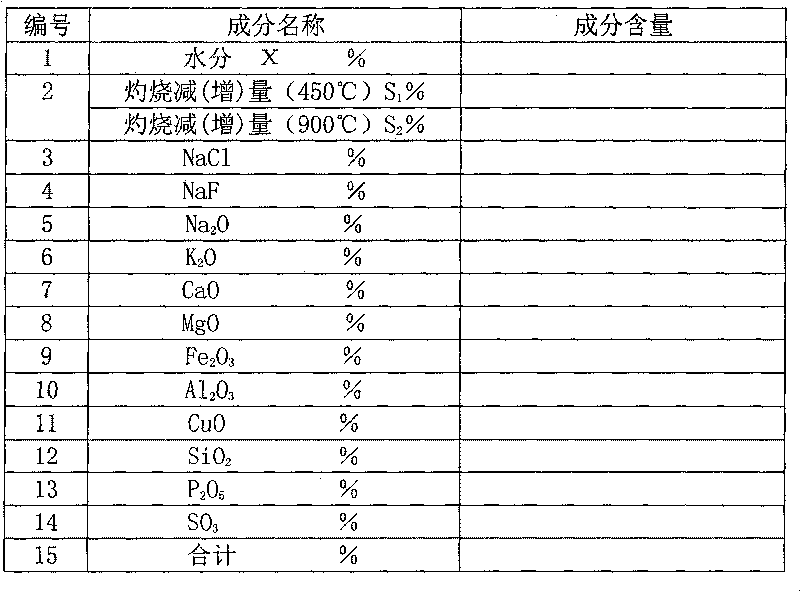

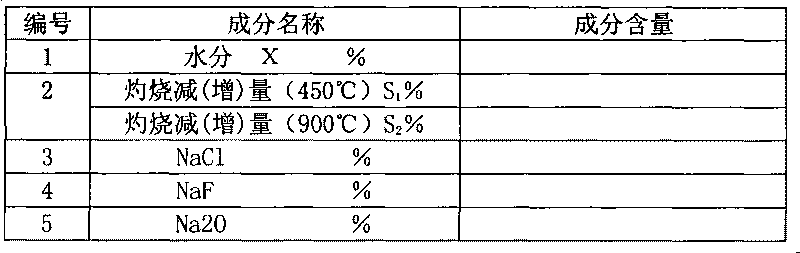

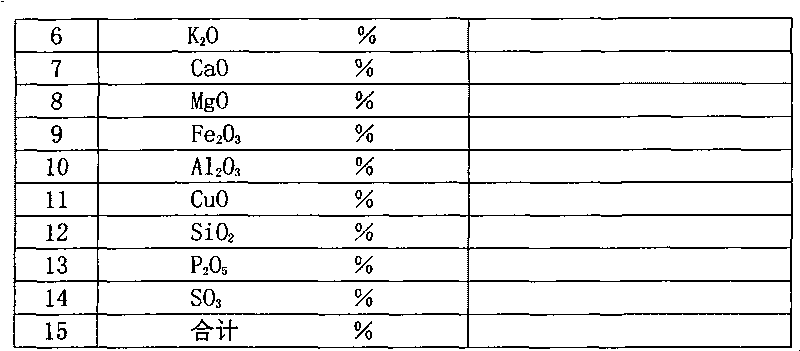

[0048] 1. Burning reduction (increase) amount S at 450°C 1 % and 900 ℃ ignition loss (increase) amount S 2 %

[0049] Accurately weigh out 0.6000 g of the scale sample of the steam turbine blade, and do an ignition loss (increase) test in a high-temperature furnace at 450 ° C to obtain the ignition loss S 1 % = 0.50%; Ignition loss (increase) test was done in a 900°C high-temperature furnace to obtain the ignition loss S 2 % = 1.50

[0050] 2. Chloride ion content Cl in the scale sample - %, fluoride ion content F - %analyze

[0051] Accurately weigh 0.5000 grams of steam turbine blade scale sample, and measure the chloride ion content Cl in the water-soluble scale sample - %=1.00%, fluoride ion content F - %=0.50%, represented by NaCl and NaF: NaCl%=1.648×Cl - %=1.648×1.0%=1.648%, NaF%=2.211×F - % = 2.211 x 0.5% = 1.106%.

[0052] 3. Na in the scale sample 2 O percentage analysis

[0053] Accurately weigh 0.2000 g of the scale sample of the steam turbine blade, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com