Electro-beam welding joint melting-coagulation area shape factor modeling and solving method

A technology of electron beam welding and form factor, which is used in electrical digital data processing, special data processing applications, instruments, etc., and can solve problems such as weak theoretical foundation of the model and no consideration of complex physical processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

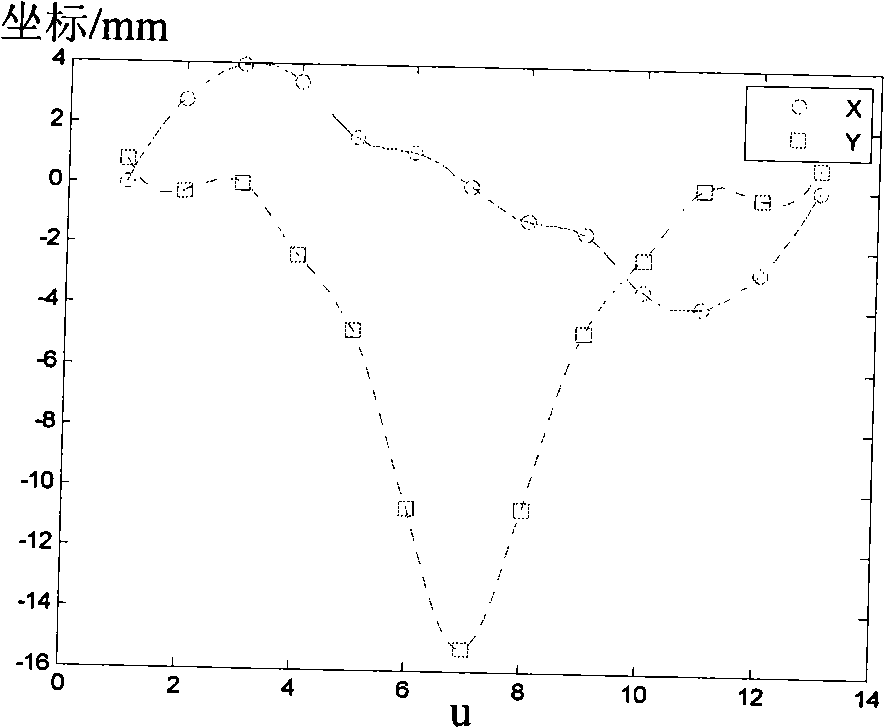

[0077] 1. Electron beam welded joint test piece

[0078] Electron beam welding of TC4 titanium alloy test plate with a thickness of 20mm and a size of 200mm×180mm:

[0079] u a - Accelerating voltage, I b - Beam I f -focus current V-welding speed, H-distance from the gun to the test piece

[0080] Parameter 1: U a =150kV, I b =48mA, I f =342mA, V=800mm / min, H=251mm, vacuum 6×10 -3 Pa

[0081] Parameter 2: U a =150kV, I b =56mA, I f =356mA, V=600mm / min, H=251mm, vacuum 8×10 -3 Pa

[0082] Parameter 3: U a =90kV, I b =61mA, I f =1675mA, V=600mm / min, H=370mm, vacuum 3.2×10 -4 Pa

[0083] Parameter 4: U a =150kV, I b =29mA, I f =342mA, V=200mm / min, H=251mm, vacuum 4×10 -3 Pa

[0084] Parameter 5: U a =90kV,I b =54mA,I f =1670mA, V=600mm / min, H=370mm, vacuum 3.0×10 -4 Pa

[0085] Parameter 6: U a =90kV,I b =97mA, I f =1654mA, V=600mm / min, H=370mm, vacuum 3.6×10 -4 Pa

[0086] Parameter 7: U a =90kV, I b=92mA, I f =1685mA, V=600mm / min, H=370mm, vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com