Fast closing mechanism of small circuit breaker

A small circuit breaker, fast closing technology, applied in circuit breaker parts, protection switch operation/release mechanism, etc., can solve the problems of reducing the breaking speed of moving contacts, increasing the difficulty of realization, limiting breaking capacity, etc. The effect of increased speed and breaking speed, low cost and increased breaking capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

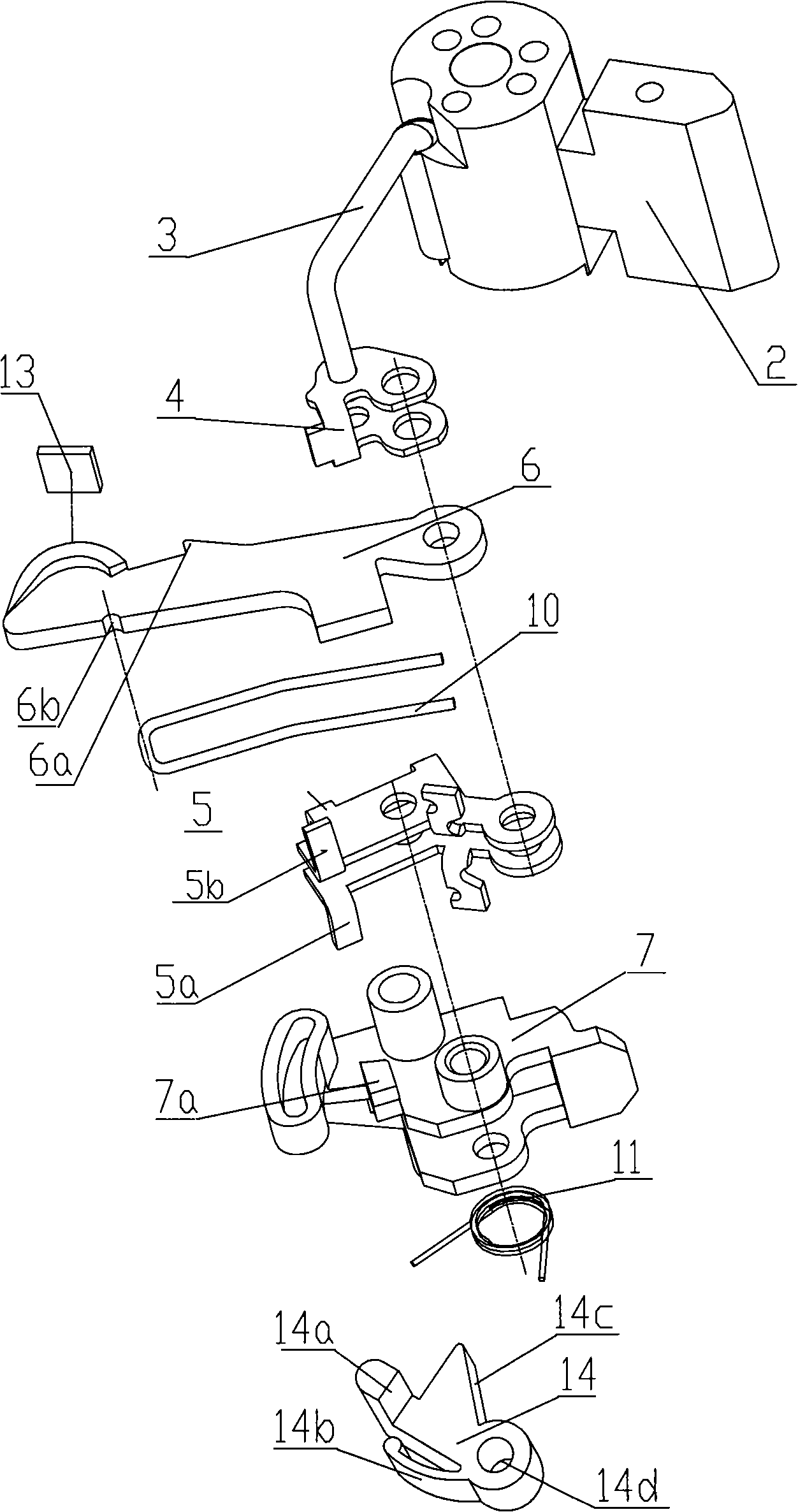

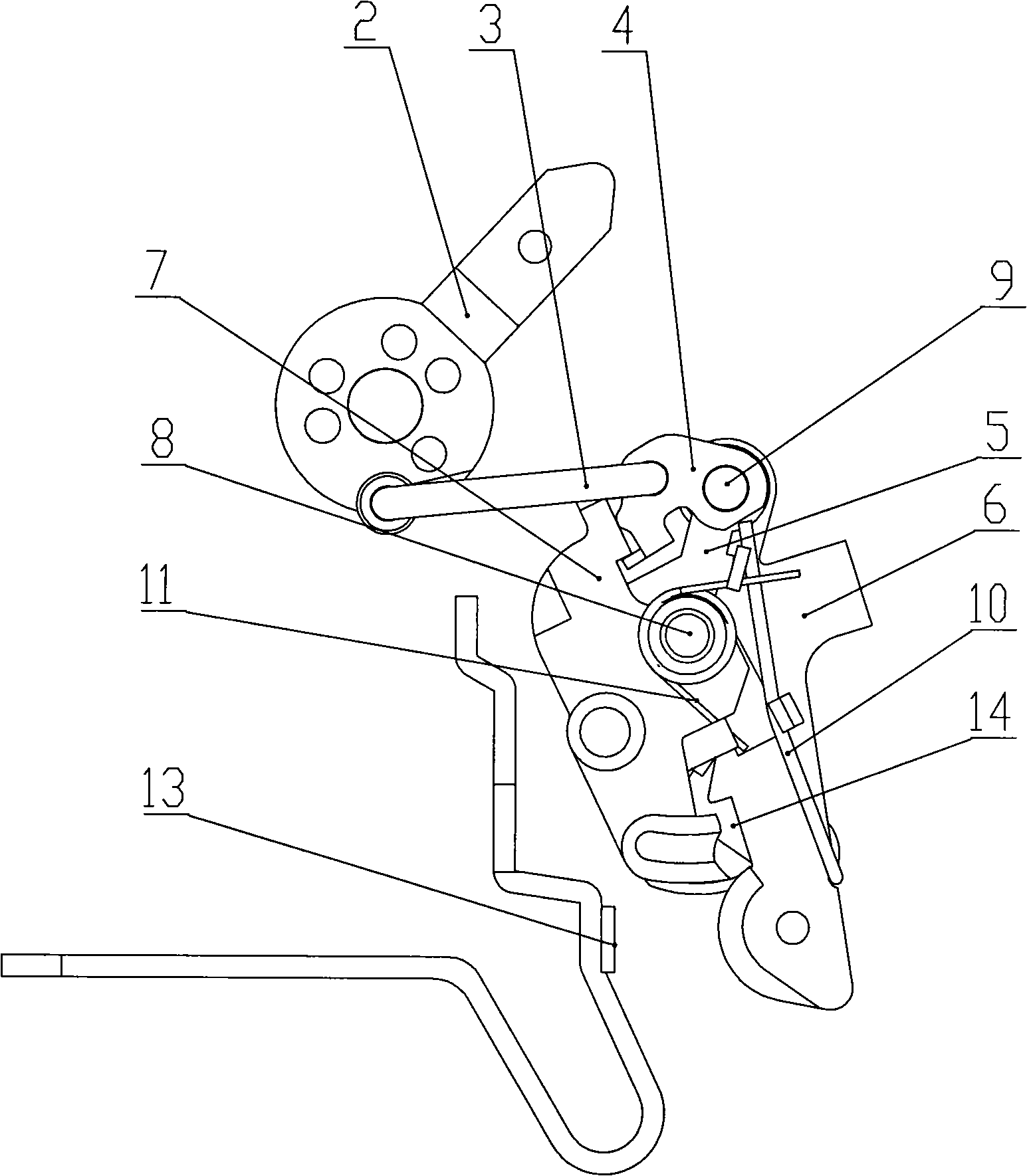

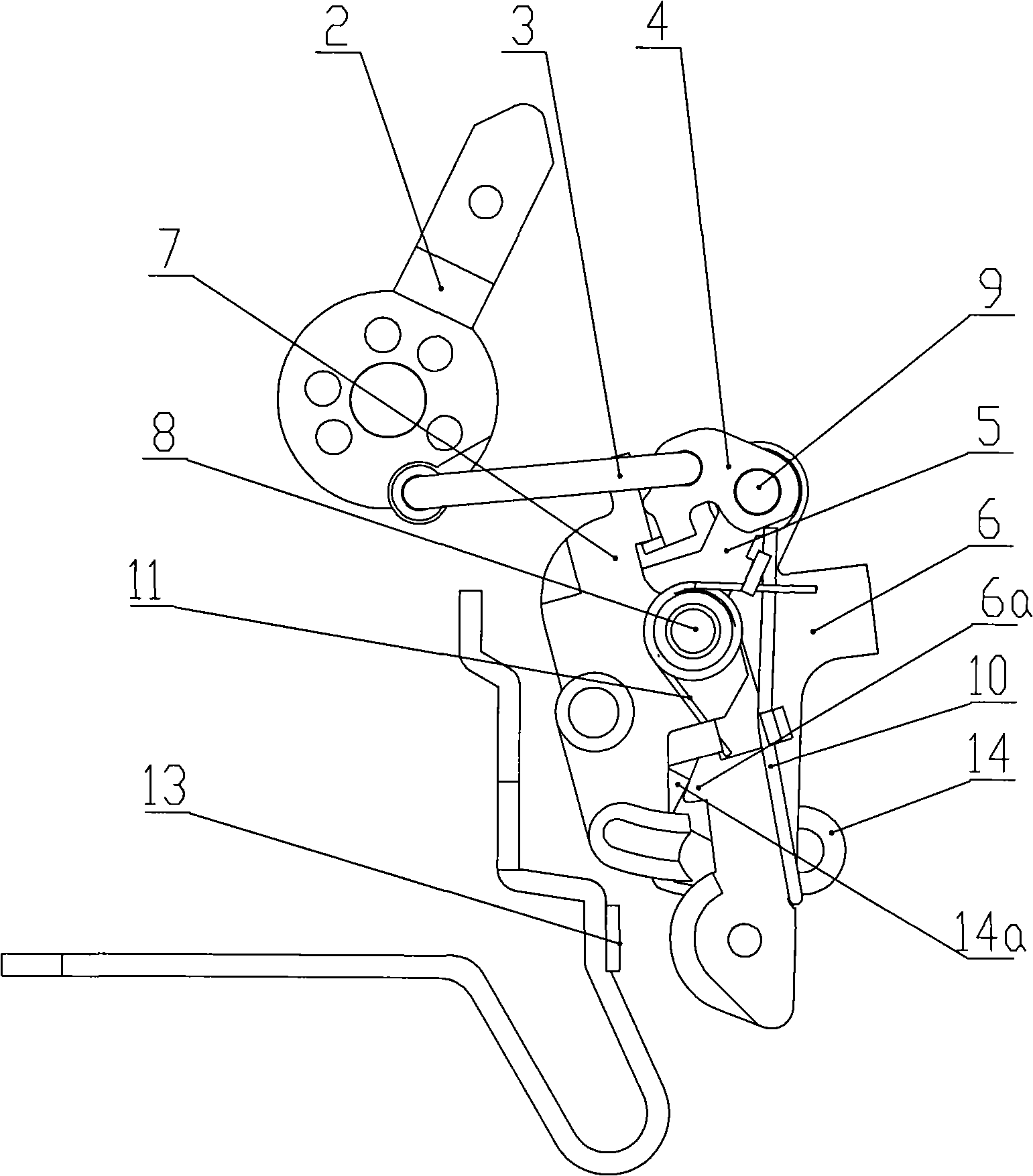

[0016] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

[0017] Such as Figure 1 to Figure 7 As shown, this embodiment includes: a housing 1, a handle 2, a connecting rod 3, a jumper 4, a lever 5 (protrusion 5a), a moving contact 6 (protrusion 6a, groove 6b), a lock 7, Main shaft 8, shaft pin 9, contact pressure spring 10, lock spring 11, energy storage spring 12, static contact 13 (welded with a hard conductor), fast closing function part 14 (boss 14a, elastic thin-wall 14b, side walls 14c and through holes 14d).

[0018] The present invention adopts the handle 2 to be installed on the shell 1, the handle 2 is connected with the connecting rod 3, the connecting rod 3 is connected with the jumper 4, the lever 5 and the moving contact 6 are connected with the operating mechanism of the circuit breaker; the fast closing function part 14 is rotated and installed on the breaker housing base. A through hole 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com