Carrier-based aircraft catapulting device for aircraft carrier

A catapult device and carrier-based aircraft technology, which is applied in electromechanical devices, launch/drag transmission devices, and mechanical energy control, etc., can solve the problems of large moving magnet moving mass, limited electromagnetic force, unfavorable take-off acceleration, etc., and achieve small motion The effect of resistance, large bearing capacity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

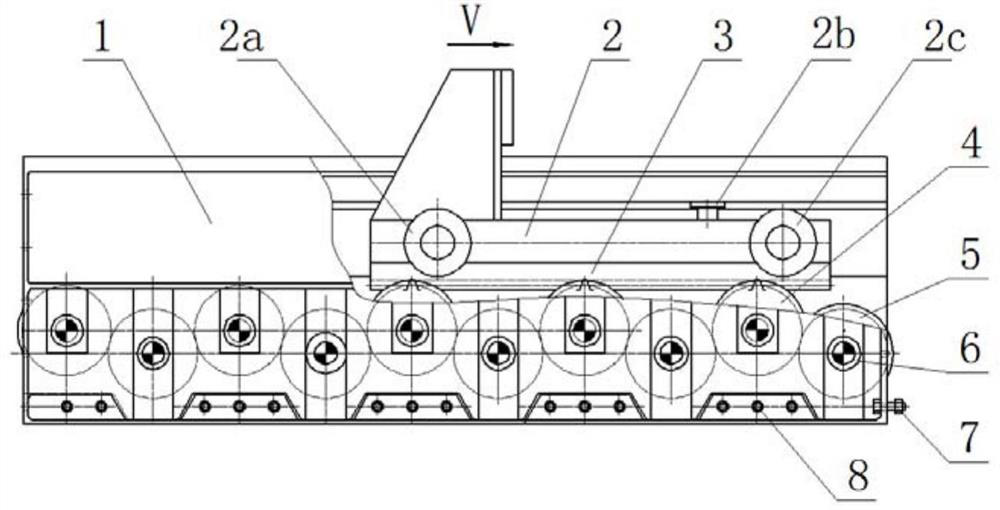

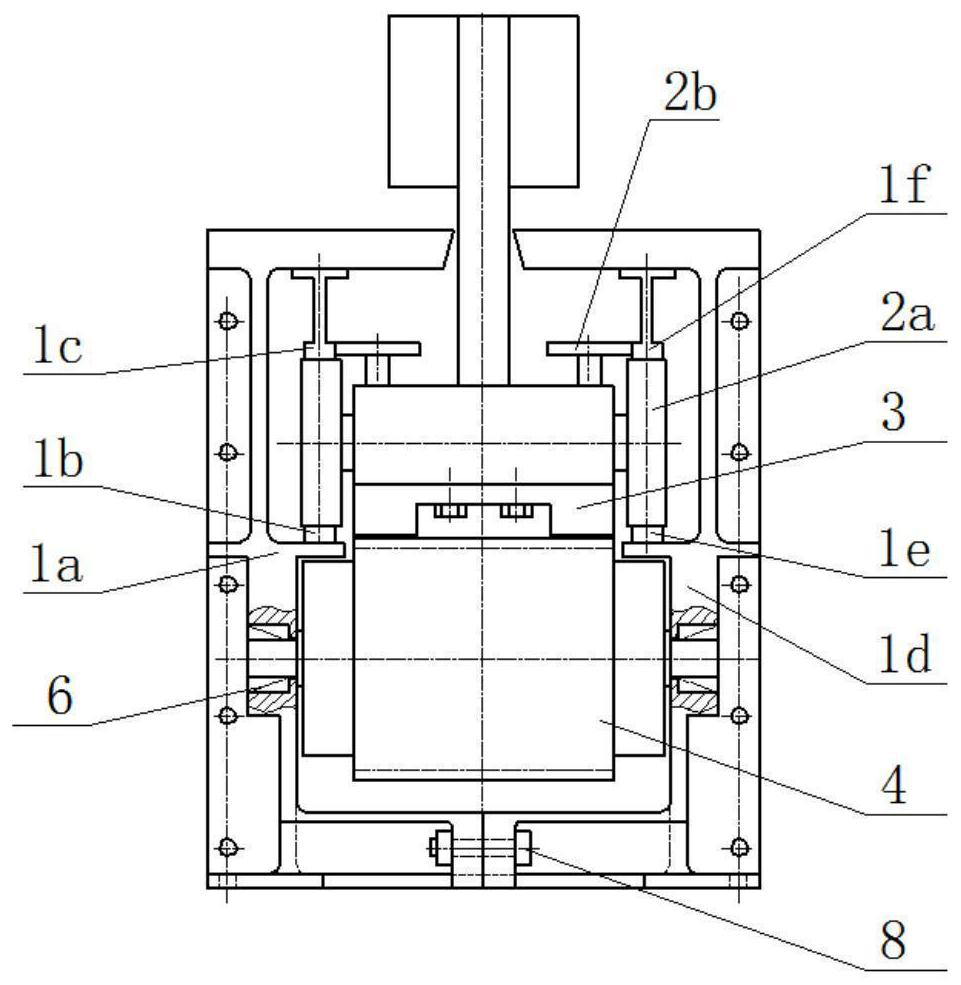

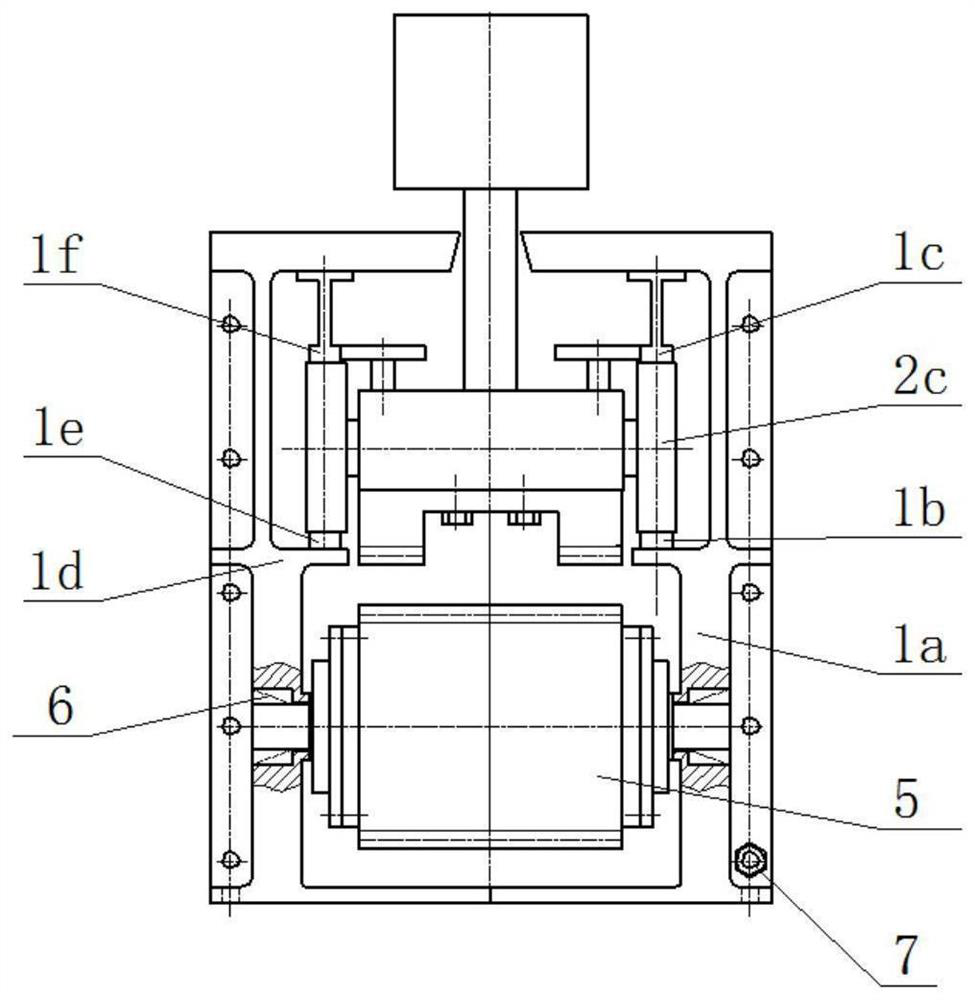

[0027] An ejection device for an aircraft carrier-based aircraft of the present invention comprises a working machine base, an ejection vehicle 2 and a tooth plate 3; The main motor 4 and the bridge motor 5 are assembled. The length of the working machine base meets the ejection requirements of aircraft carriers.

[0028] figure 1Among them, the frame unit 1 is assembled with the main motor 4 and the bridge motor 5 to form a base unit, and the front and rear of the base unit are connected by longitudinal bolt groups 7 to form working bases with different lengths. The longitudinal bolt group 7 includes bolts, nuts and washers. The base unit shown in the figure is equipped with 5 main motors 4 and 5 bridge motors 5, the main motor 4 and the bridge motor 5 are both outer rotor motors, and the two ends of the stator shaft of the outer rotor motor are respectively connected by the fastener 6 and the The rack unit 1 is firmly connected. The axes of the main motor 4 and the bridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com