Assembling device and method for display panel and a treatment device thereof and a baseplate delivery mechanism

A display panel and assembly device technology, which is applied in the direction of conveyor objects, furnace components, transportation and packaging, etc., can solve the problems of long length of display panel module assembly device and increased number of processing operation devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0119] Below, use Figure 1 to Figure 5 One embodiment of the present invention will be described.

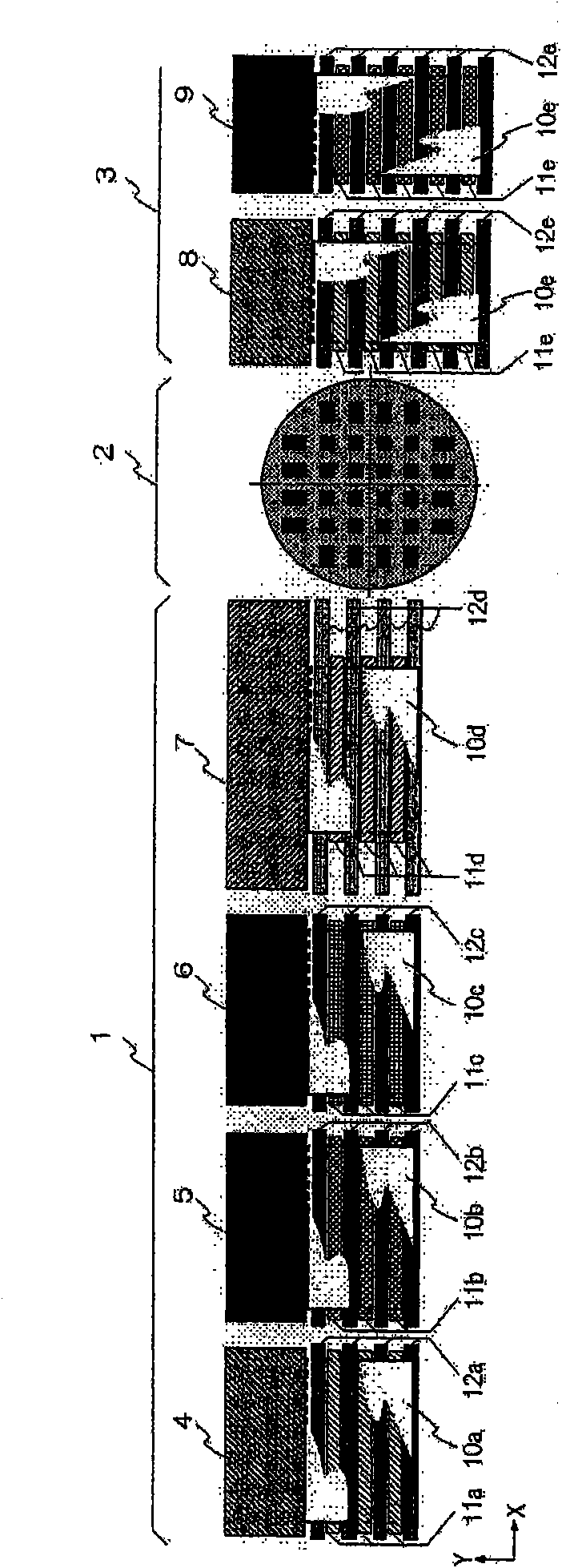

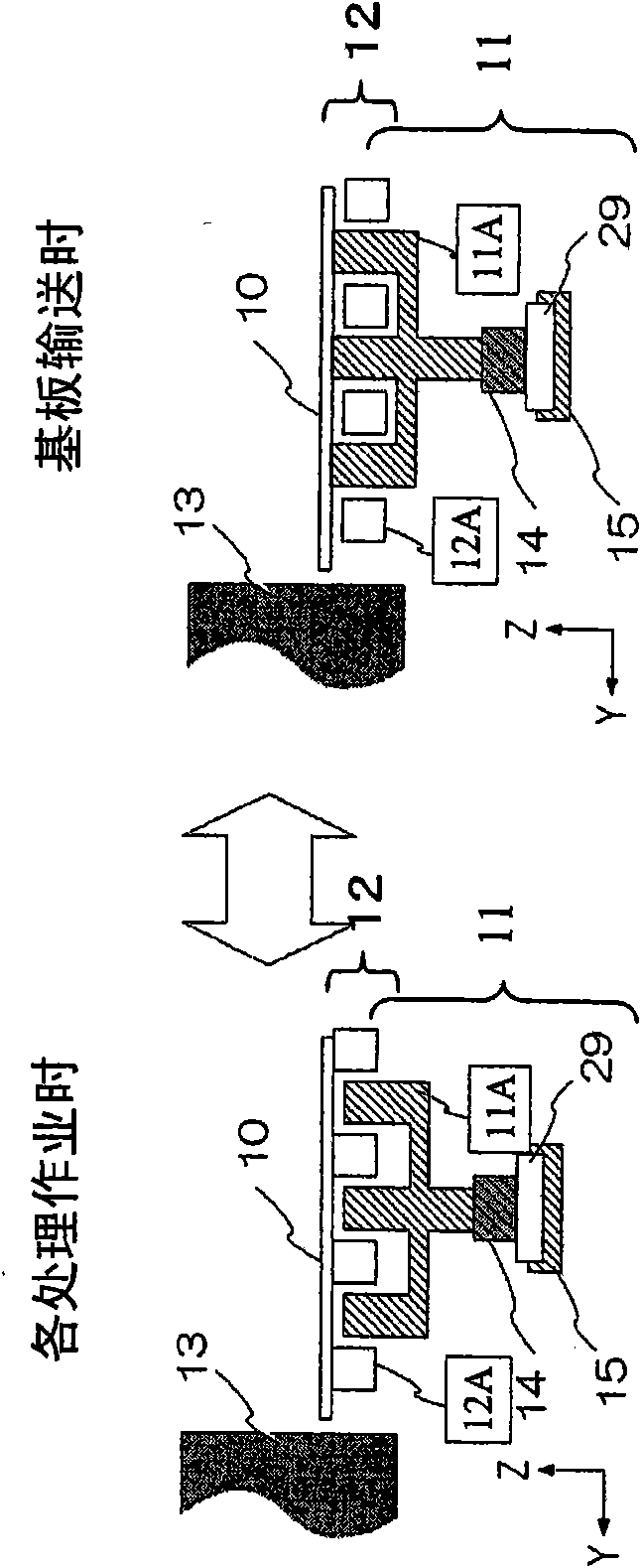

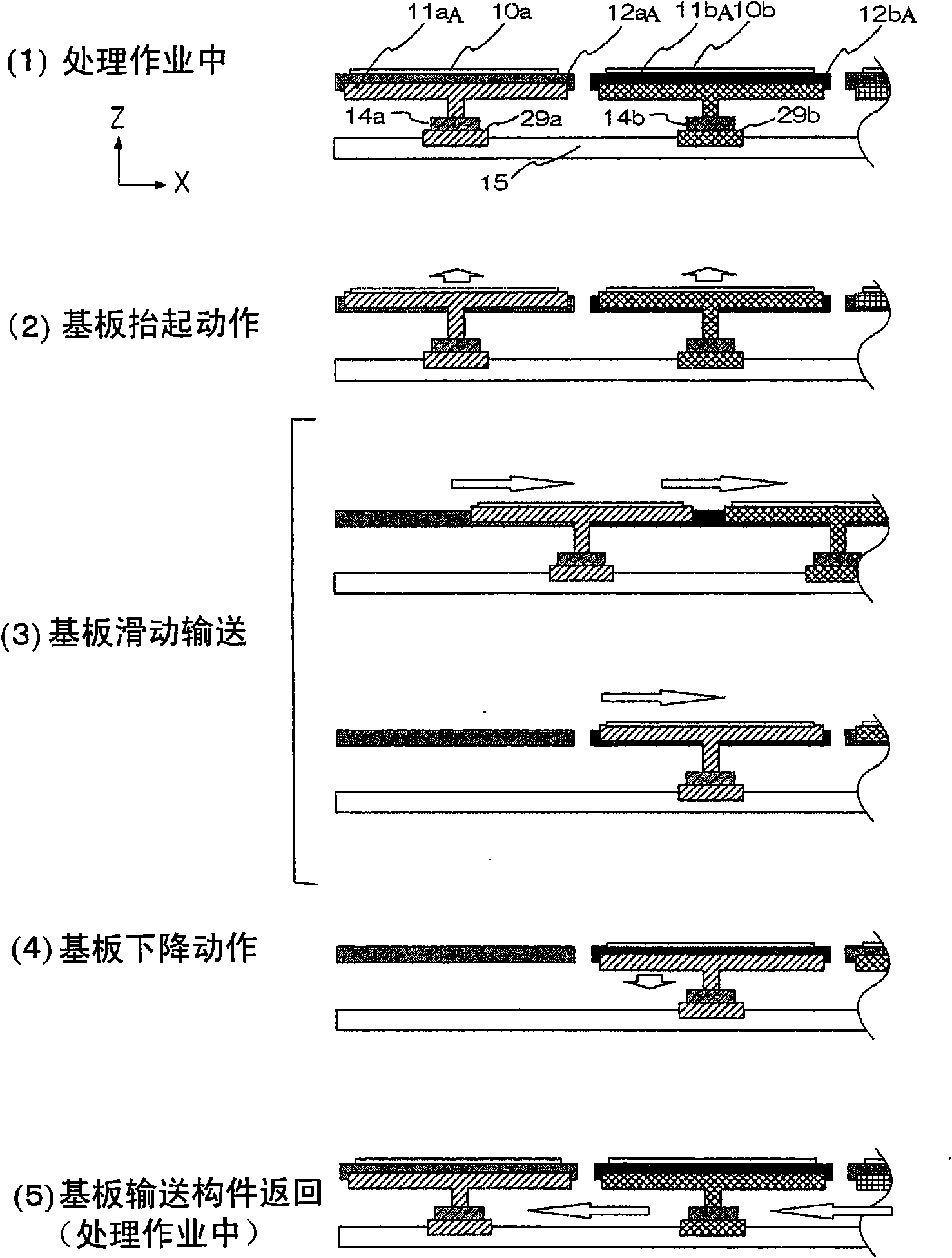

[0120] figure 1 It is a figure which shows one Example for demonstrating the basic structure of the display panel board|substrate conveyance apparatus of this invention, and the display panel module assembly apparatus using the same.

[0121] figure 1 The device in FIG. 1 is a device that sequentially transports the substrate 10 from left to right in the figure, and performs various processing operations on the peripheral portion of the substrate, and performs mounting and assembling operations such as ICs and TABs. exist figure 1 In the device, firstly, after processing the long side (source side) of the substrate using the processing unit 1 on the long side (source side) of the substrate, the substrate is rotated by the rotary table 2, and secondly, the short side of the substrate is used to The processing operation device group 3 (gate side) performs processing operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com